Blue light conversion diffusion barrier

A diffusion film and optical conversion technology, applied in the direction of optics, optical filters, optical components, etc., can solve the problems of increased toxins in the macular area, excessive blue light, low color rendering, etc., to avoid damage, reduce blue light radiation, Improves the effect of color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

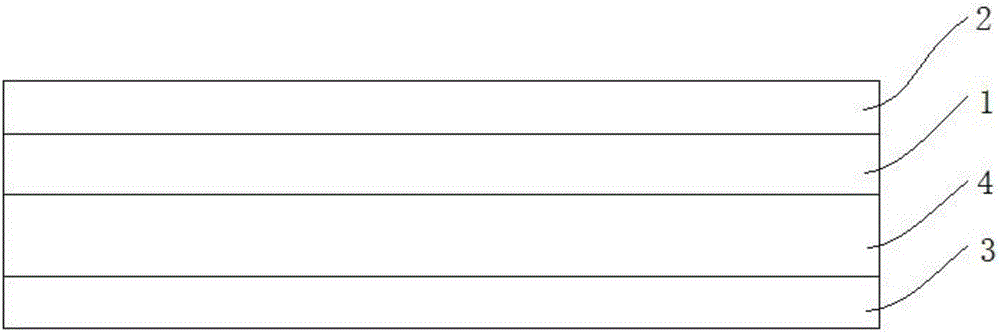

[0032] Such as figure 1 The structure of the diffusion film shown is, from top to bottom, an optical diffusion coating 2 with a thickness of 10 μm, a transparent substrate 1 of cellulose triacetate film with a thickness of 10 μm, a single-layer optical conversion layer 4 with a thickness of 50 μm, and a thickness of 10 μm. 10 μm isolation layer 3 .

[0033] The optical diffusion coating 2 of this embodiment is composed of polyester resin and acrylic diffusion particles; the material used for the isolation layer 3 is acrylic resin; the optical conversion material of the optical conversion layer 4 is a rare earth fluorescent material: Eu 2+ Doped phosphor, the transparent resin is epoxy resin, the mass ratio of rare earth fluorescent material to transparent resin is 2:100, Eu 2+ The doped fluorescent powder is dispersed in the epoxy resin by ultrasound, and fixed on the surface of the transparent substrate 1 by coating. Eu 2+ The doped phosphor can be excited by blue light w...

Embodiment 2

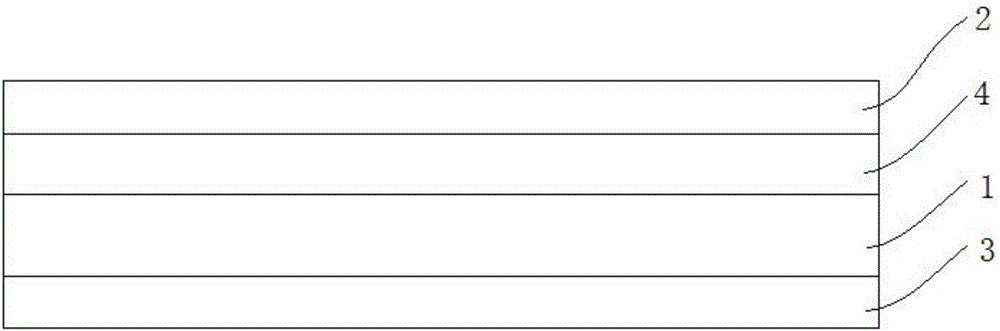

[0035] Such as figure 2 The structure of the diffusion film shown is, from top to bottom, an optical diffusion coating 2 with a thickness of 10 μm, a single-layer optical conversion layer 4 with a thickness of 1 μm, and a PET (polyethylene terephthalate) with a thickness of 50 μm Transparent substrate 1, isolation layer 3 with a thickness of 10 μm.

[0036] The optical diffusion coating 2 in this implementation case is composed of polyester resin and acrylic diffusion particles; the material used for the isolation layer 3 is acrylic resin; the optical conversion material of the optical conversion layer 4 is a rare earth fluorescent material: Eu 2+ A mixed material doped with fluorescent powder and xanthene derivatives, the transparent resin is acrylic resin, the mass ratio of the light conversion material to the transparent resin is 1.5:100, and the light conversion material is dispersed in the acrylic resin by high-speed shearing. The cloth method is fixed on the surface of...

Embodiment 3

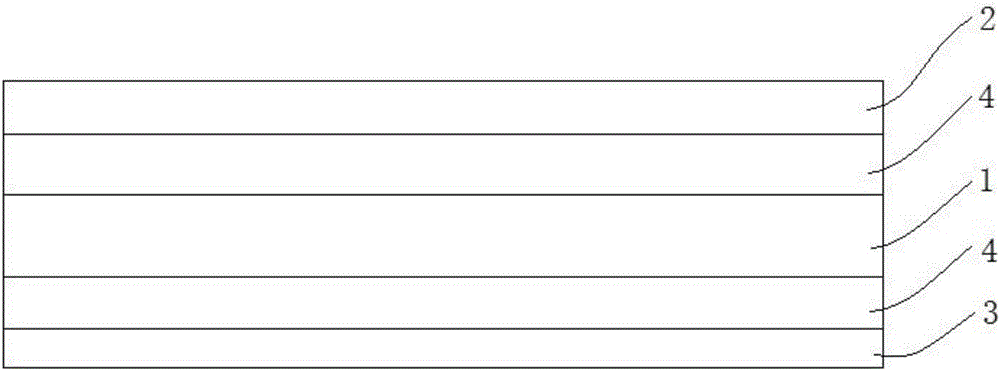

[0038] Such as image 3 The structure of the diffusion film shown is, from top to bottom, an optical diffusion coating 2 with a thickness of 10 μm, a single-layer optical conversion layer 4 with a thickness of 100 nm, and a transparent substrate 1 of polycarbonate film with a thickness of 100 μm and a thickness of 100 nm. A single-layer optical conversion layer 4 and an isolation layer 3 with a thickness of 10 μm.

[0039] The optical diffusion coating 2 of this embodiment is composed of polyester resin and acrylic diffusion particles; the material used for the isolation layer 3 is acrylic resin; the optical conversion material of the optical conversion layer 4 located above the transparent substrate 1 is an organic small molecule fluorescent dye oxygen Xanthene derivatives, the transparent resin is polyester resin, the mass ratio of xanthene derivatives to polyester resin is 0.01:100, and the xanthene derivatives are dissolved in isopropanol solvent and mixed with polyester r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com