A kind of PDMS-PTFE transparent film and preparation method thereof for improving the performance of nano triboelectric generator

A technology of PDMS-PTFE and nano friction, which is applied in the field of friction nano power generation, can solve the problems of different application fields and the inability to make transparent films, etc., and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

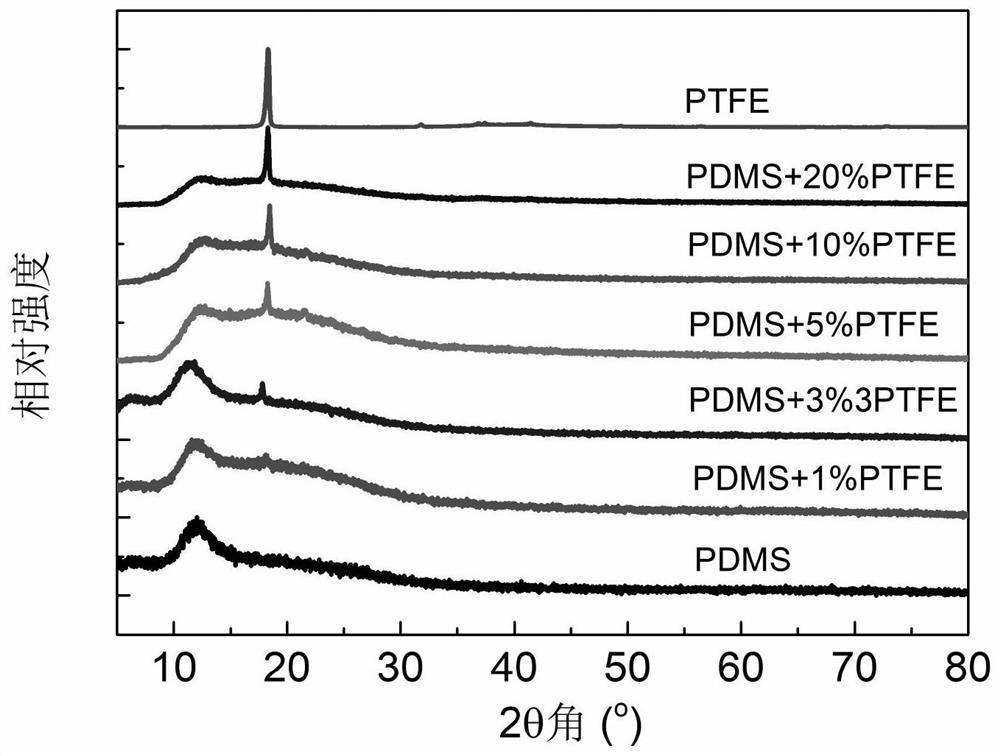

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 10g polydimethylsiloxane prepolymer and dissolve it in 0.1g n-hexane, mix and stir for 10min, so that the two are fully mixed evenly;

[0039] (2) Add PTFE emulsion (the net content of PTFE is 0.1g) to the mixed solution, and heat to 100°C and stir for 0.5h to prepare a mixed solution;

[0040] (3) Cool the above mixed solution to room temperature, add 0.8g tetraethyl orthosilicate cross-linking agent, then add 0.3g dibutyltin dilaurate catalyst, stir at room temperature for 0.5h to prepare uniformly mixed PDMS solution to be solidified; and carry out Degassing treatment to prepare a uniform and bubble-free PDMS solution to be cured;

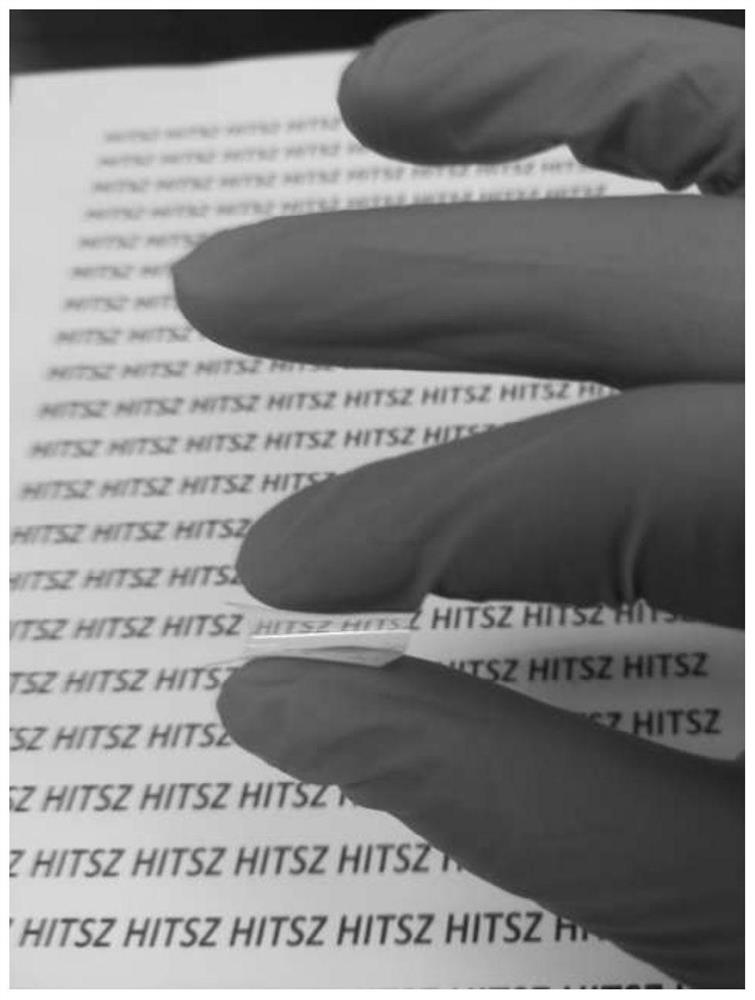

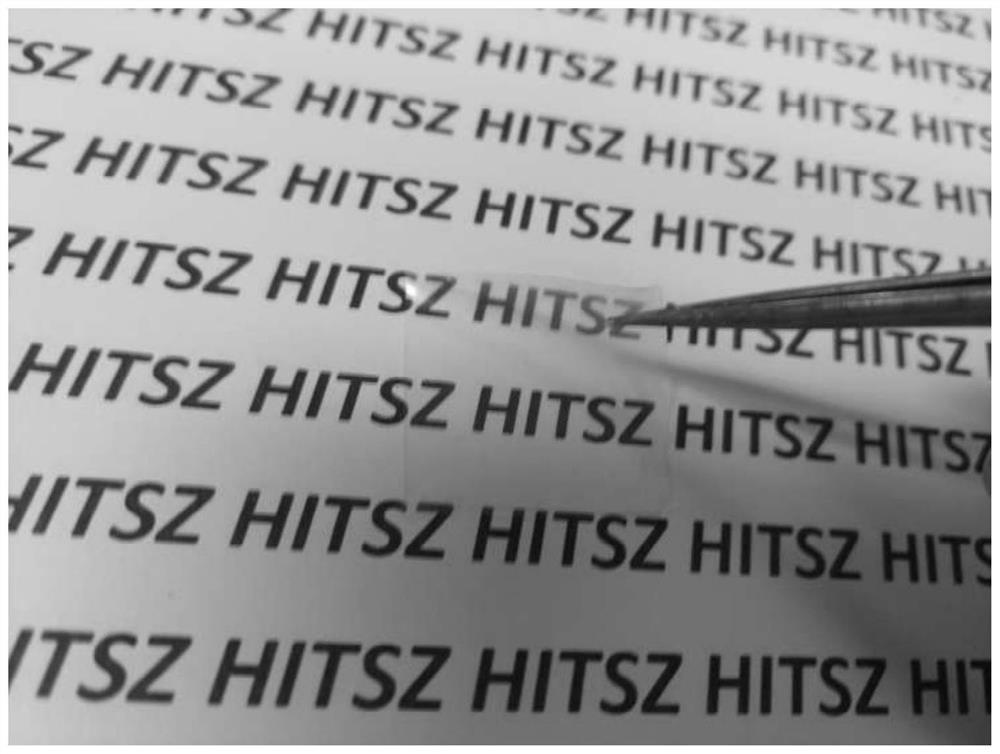

[0041] (4) The above solution was coated on the substrate glass of the nanogenerator, and cured at 40° C. for 8 hours, and the film was peeled off from the substrate to prepare a PDMS-PTFE film.

Embodiment 2

[0043] (1) Weigh 10g of polydimethylsiloxane prepolymer and dissolve it in 1g of n-hexane, mix and stir for 5min, so that the two are fully mixed evenly;

[0044] (2) Add PTFE emulsion (wherein the net content of PTFE is 0.3g) to the mixed solution, and stir for 5 hours in a hot environment at 60°C to prepare a mixed solution;

[0045] (3) Cool the above mixed solution to room temperature, add 0.9g tetraethyl orthosilicate crosslinking agent, then add 0.3g dibutyltin dilaurate catalyst, stir at room temperature for 0.5h to obtain a uniformly mixed PDMS solution to be solidified, and carry out Degassing treatment to prepare a uniform and bubble-free PDMS solution to be cured;

[0046] (4) Coating the above-mentioned solution on the substrate silicon wafer of the nanogenerator, and curing at 60° C. for 6 hours, peeling off the film from the substrate to prepare a PDMS-PTFE film.

Embodiment 3

[0048] (1) By weight, take 10g of polydimethylsiloxane prepolymer and dissolve it in 1g of n-hexane, mix and stir for 5min, so that the two are fully mixed evenly;

[0049] (2) Add PTFE emulsion (wherein the net content of PTFE is 0.5g) to the mixed solution, and stir in a hot environment of 70°C for 3.5h to prepare a mixed solution;

[0050] (3) Cool the above mixed solution to room temperature, add 1g of tetraethyl orthosilicate crosslinking agent, then add 0.2g of dibutyltin dilaurate catalyst, stir at room temperature for 1h to obtain a uniformly mixed PDMS solution to be solidified, and remove it Gas treatment to obtain a uniform and bubble-free PDMS solution to be cured;

[0051] (4) The above solution was coated on the substrate PET plate of the nanogenerator, and cured at 120° C. for 20 minutes, and the film was peeled off from the substrate to obtain a PDMS-PTFE film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com