Method for preparing chitooligosaccharide with snailase and application thereof

A technology of snail enzyme and chitosan oligosaccharide, which is applied in the direction of medical preparations, applications, and pharmaceutical formulas containing active ingredients, and can solve the problems of limited source of specific enzymes, many steps in chemical degradation methods, and low efficiency of single enzyme degradation, etc. problems, achieve good industrial promotion practicability and value, improve idiopathic pulmonary fibrosis, and improve the effect of lung fibroblast activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a kind of method that prepares chitosan oligosaccharide with helicase

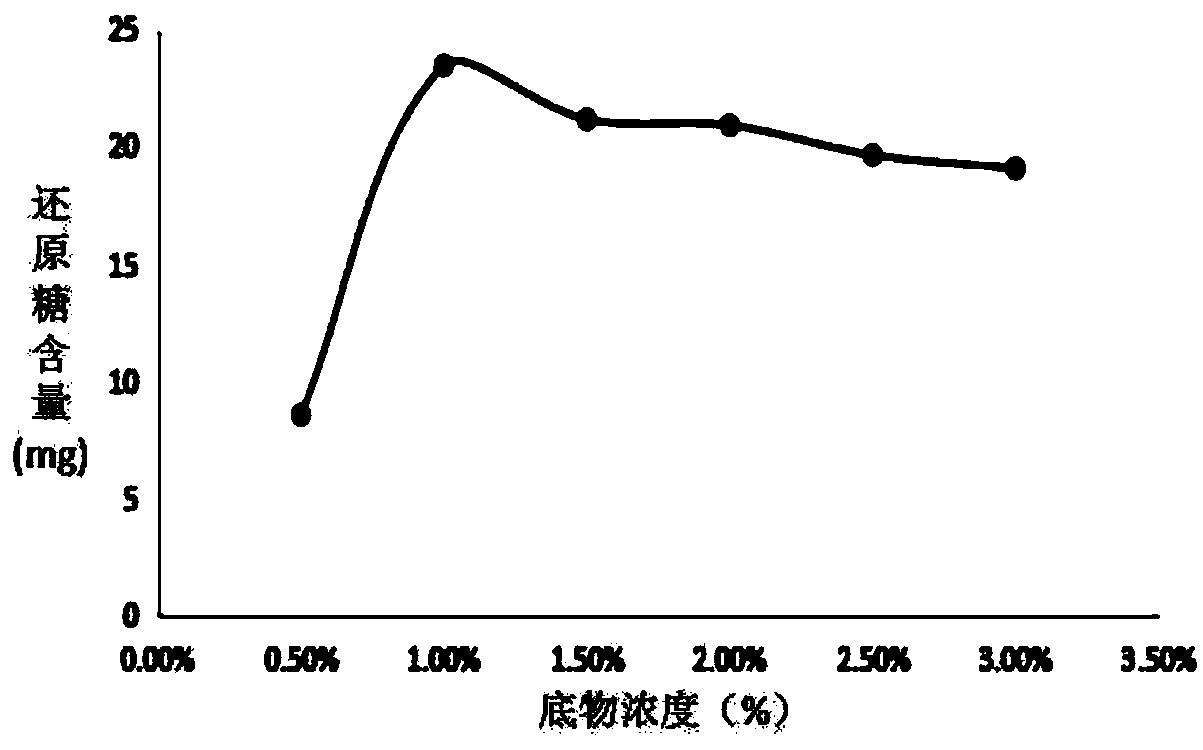

[0037] S1 Take the chitosan raw material and dry it to constant weight, dissolve it in 0.2mol / L acetic acid-sodium acetate buffer solution with a pH value of 4.5, stir and dissolve, and prepare a chitosan solution with a mass concentration of 1.0%;

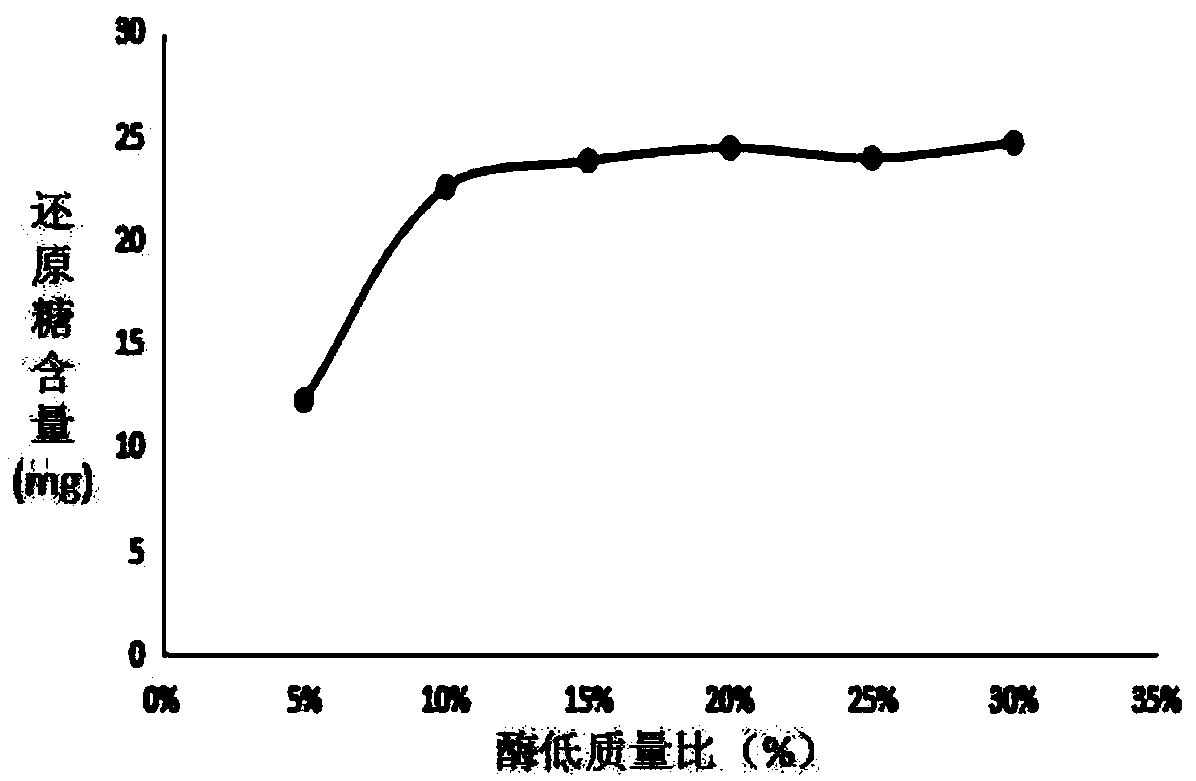

[0038]S2 Adding a helicase solution with a mass concentration of 1.0% to the chitosan solution obtained in step S1, the mass ratio of the helicase to the chitosan substrate is 1:10, after enzymolysis in a water bath at 40°C for 2.5h, Inactivate in a water bath at 100°C for 10 minutes, cool to room temperature, stir continuously, add dropwise NaOH solution with a mass concentration of 5%, adjust the pH value to 4.5, filter, and collect the filtrate;

[0039] S3 put the filtrate obtained in step S2 into a dialysis device with a regenerated cellulose dialysis bag with a molecular weight cut-off of 3000 Da in the inner layer and a regenerated ...

Embodiment 2

[0041] Embodiment 2, a kind of method that prepares chitosan oligosaccharide with helicase

[0042] S1 Take the chitosan raw material and dry it to constant weight, dissolve it in 0.2mol / L acetic acid-sodium acetate buffer solution with a pH value of 4.5, stir and dissolve, and prepare a chitosan solution with a mass concentration of 1.0%;

[0043] S2 adds the helicase solution that mass concentration is 1.0% to the chitosan solution obtained in step S1, and described helicase and chitosan substrate mass ratio are 1:10, after enzymolysis 2h in 40 ℃ of water bath boxes, 100 Inactivate in a water bath at ℃ for 15 minutes, cool to room temperature, stir continuously, add NaOH solution with a mass concentration of 5% dropwise, adjust the pH value to 6, filter, and collect the filtrate;

[0044] S3 put the filtrate obtained in step S2 into a dialysis device with a regenerated cellulose dialysis bag with a molecular weight cut-off of 3000 Da in the inner layer and a regenerated cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com