Silkworm cocoon drying method for improving mechanical properties and thermal stability of silk

A drying method and thermally stable technology, applied in the direction of heating to dry solid materials, drying solid materials, lighting and heating equipment, etc., can solve the problem that cocoon drying technology cannot be improved, drying technology is fixed, silk mechanical properties and thermal stability performance Can not be improved and other problems, to achieve the effect of promoting further development, shortening drying time, and increasing the temperature at the point of weight loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

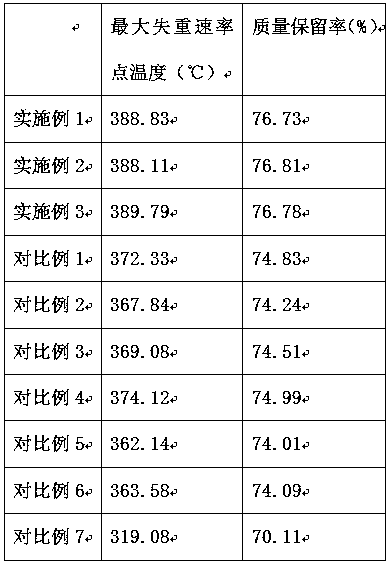

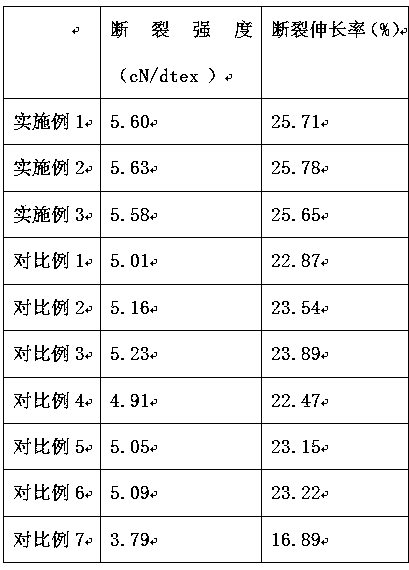

Examples

Embodiment 1

[0015] In the embodiment of the present invention, a cocoon drying method for improving the mechanical properties and thermal stability of silk, the specific method is as follows:

[0016] (1) Put the fresh silkworm cocoons into the electric field for electric field treatment, immerse them in the sodium alginate solution at a temperature of 49°C and soak for 18 minutes, drain the liquid, and drain until there is no water dripping, and put it into the condition at a temperature of 0.3°C Refrigerate at a constant temperature for 22 minutes, raise the temperature to 6.7°C at a heating rate of 0.3°C / min, continue to refrigerate at a constant temperature for 34 minutes, and dry in microwave for 10 minutes at a temperature of 73°C and a power of 66W to obtain pre-dried cocoons;

[0017] (2) Submerge the pre-dried cocoons in the treatment agent for 31 minutes, remove the agent, drain until no water drips, and perform nitrogen plasma treatment. Microwave drying treatment is performed a...

Embodiment 2

[0023] In the embodiment of the present invention, a cocoon drying method for improving the mechanical properties and thermal stability of silk, the specific method is as follows:

[0024] (1) Put the fresh silkworm cocoons in the electric field for electric field treatment, immerse them in the sodium alginate solution at a temperature of 50°C for 20 minutes, drain the liquid, and drain until there is no water drop, and put it in the condition of a temperature of 0.5°C Refrigerate at a constant temperature for 24 minutes, raise the temperature to 6.9°C at a heating rate of 0.35°C / min, continue to refrigerate at a constant temperature for 36 minutes, and dry in microwave for 11 minutes at a temperature of 74°C and a power of 68W to obtain pre-dried cocoons;

[0025] (2) Submerge the pre-dried cocoons in the treatment agent for 33 minutes, remove the agent, drain until no water drips, perform nitrogen plasma treatment, and microwave drying treatment at a temperature of 65°C and a...

Embodiment 3

[0031] In the embodiment of the present invention, a cocoon drying method for improving the mechanical properties and thermal stability of silk, the specific method is as follows:

[0032] (1) Put the fresh silkworm cocoons into the electric field for electric field treatment, immerse them in the sodium alginate solution at a temperature of 51°C for 22 minutes, drain the liquid, and drain until there is no water drop, and put it in the condition of 0.7°C Refrigerate at a constant temperature for 26 minutes, raise the temperature to 7.1°C at a heating rate of 0.4°C / min, continue to refrigerate at a constant temperature for 38 minutes, and dry in microwave for 12 minutes at a temperature of 75°C and a power of 70W to obtain pre-dried cocoons;

[0033] (2) Submerge the pre-dried cocoons in the treatment agent for 35 minutes, remove the agent, drain until no water drips down, perform nitrogen plasma treatment, and microwave dry treatment for 30 minutes at a temperature of 66°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com