Z-type natural gas moisture real-time measuring device and method based on in-pipe phase separation

A technology for real-time measurement and natural gas, applied in measuring devices, volumetric flow measuring devices, liquid/fluid solid measurement, etc., can solve problems such as high production process and operating environment, high process and operation requirements, and increased moisture retention time , to achieve the effects of compact structure, high operational safety performance, low processing technology and production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and the present invention will become clearer and easier to understand by illustrating.

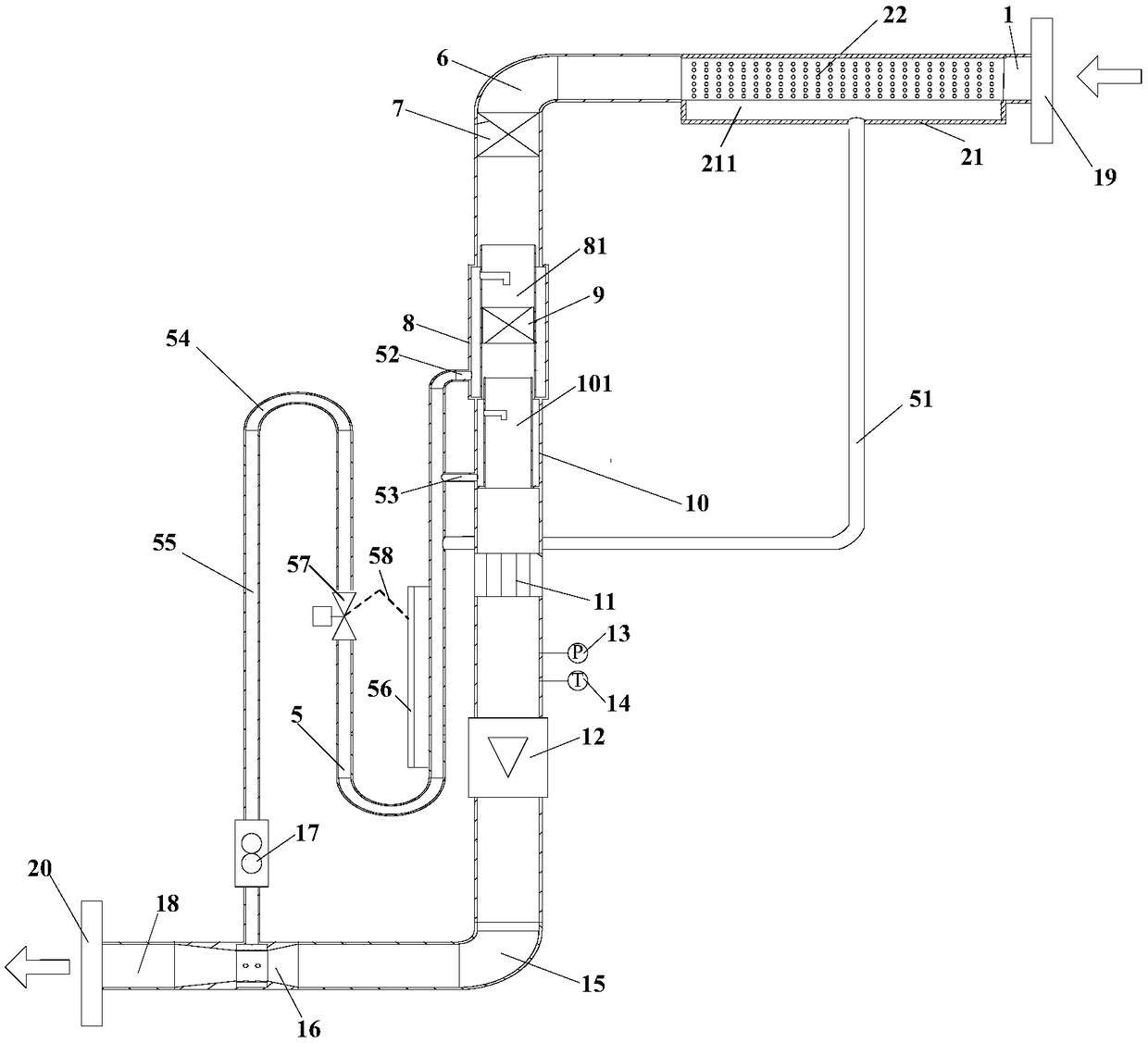

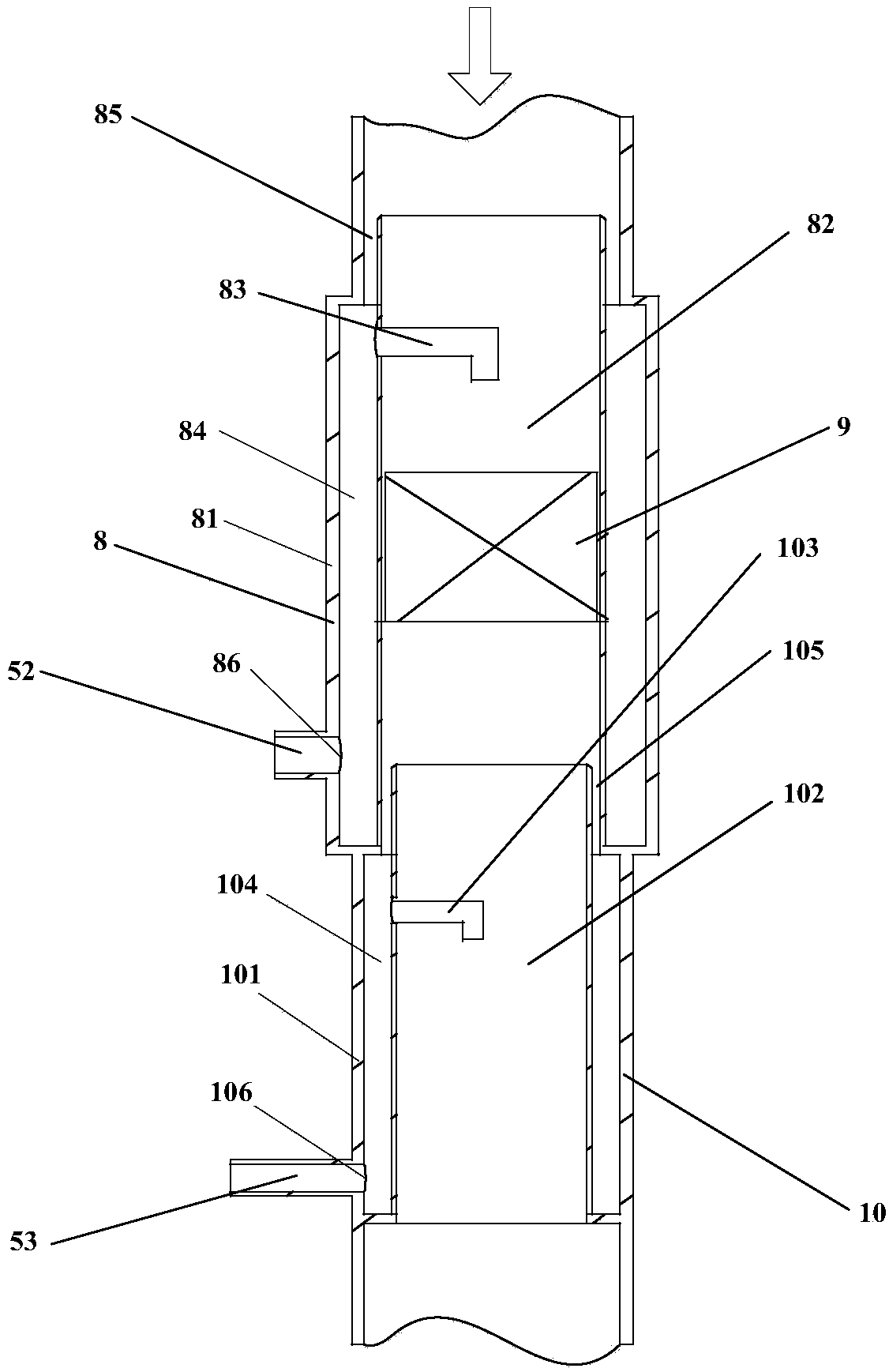

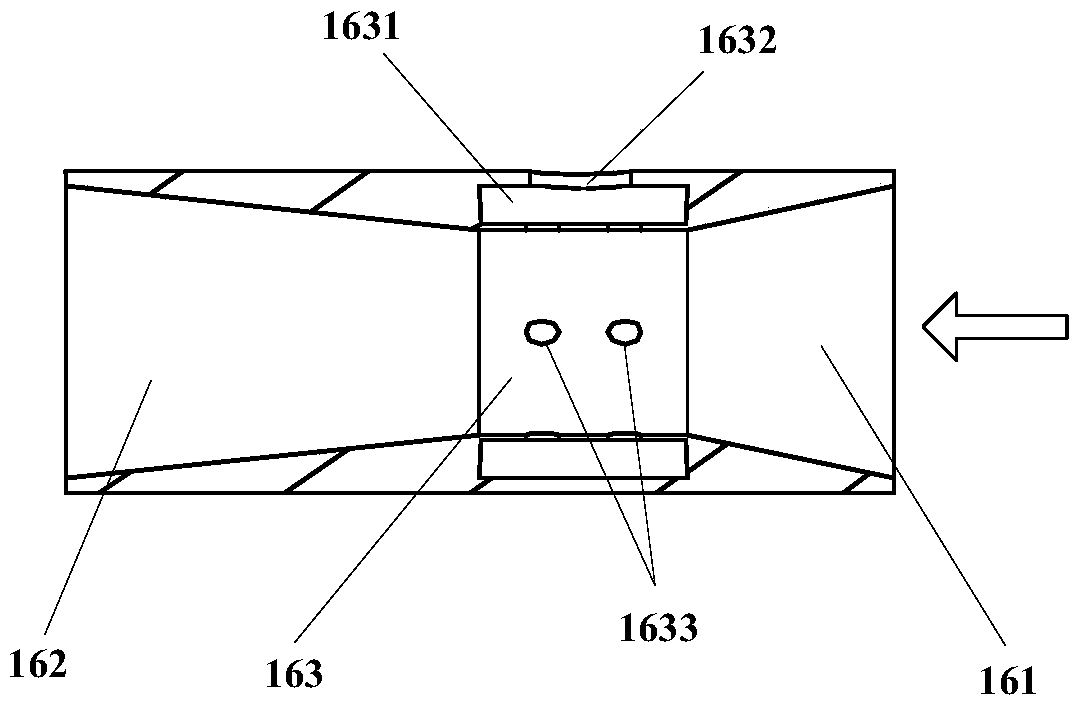

[0041] Such as figure 1 As shown, based on the Z-type natural gas moisture real-time measurement device separated in the pipe, it includes a horizontal inlet pipe 1, an upper horizontal pipeline 6, a lower horizontal pipeline 15, and a horizontal outlet pipe 18. It is characterized in that it also includes a gas-liquid rough separation system, a gas-liquid Liquid separation system, gas metering system, gas-liquid mixing system and liquid metering system; the gas-liquid rough separation system is arranged between the horizontal inlet pipe 1 and the upper horizontal pipeline 6; the gas-liquid separation system and the gas metering system are arranged in sequence On the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com