Method for determining components of medium and low-temperature coal tar on basis of mixed internal standard method

A technology of low-temperature coal tar and internal standard method, which is applied in the direction of measuring devices, material separation, and analysis of materials, can solve the problems of weak quantitative analysis ability and achieve the effect of convenient qualitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

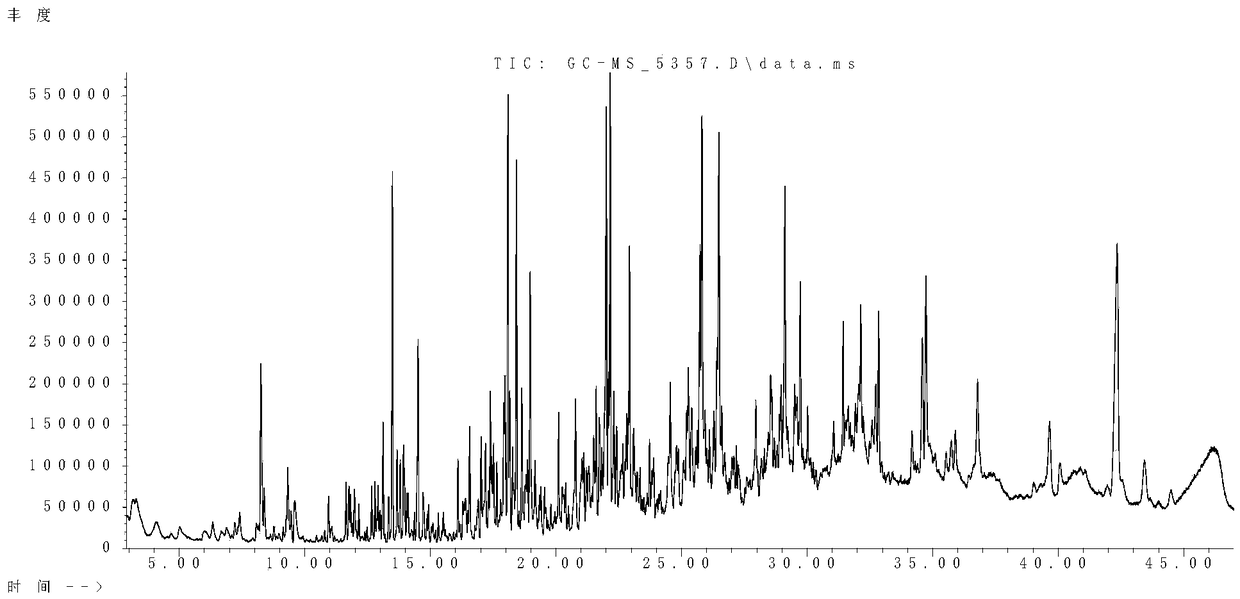

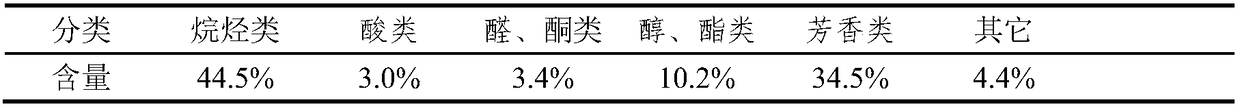

Image

Examples

Embodiment 1

[0035] Example 1: The method of the present invention for determining the components of medium and low temperature coal tar based on the mixed internal standard method is suitable for medium and low temperature coal tar, clear oil of medium and low temperature coal tar, and heavy oil of medium and low temperature coal tar.

[0036] Detect the components of medium and low temperature coal tar provided by Yulin Coal Chemical Industry Promotion Center (known to contain five components)

[0037] 1. Sample preparation

[0038] Accurately weigh 1,3,5-tri-tert-butylbenzene (purity greater than 99.5%, the same below) triphenylene, methyl nonadecanate, 2,4-dichlorobenzoic acid, 4-bromobenzaldehyde each 1mg Dissolved in acetone (analytical grade), 10mL volumetric flask to constant volume, configured into a mixed standard solution of 1mg / ml; accurately weigh 1mg of medium and low temperature coal tar (provided by Yulin Coal Chemical Industry Promotion Center), dissolve in 1ml of acetone,...

Embodiment 2

[0058] Example 2: Accuracy experiment, respectively take 0.01mg / ml, 0.5mg / ml, 1mg / ml, 2mg / ml, 5mg / ml, 10mg / ml, 20mg / ml mixed standard solution, and 1mg medium and low temperature coal tar The mixture dissolved in 1ml of acetone was measured by the same method as in Example 1, and the results showed that the linear range was 0.02mg / ml-10mg / ml. In this linear range, the accuracy of the method is high.

[0059] Control test: Take the acetone solution of methyl nonadecanoate with a concentration of 10mg / ml, and dilute it 10 times, 100 times, 1000 times, 10000 times respectively, that is, the final concentrations are 0.01mg / ml, 0.001mg / ml, 0.0001 mg / ml, 0.00001mg / ml, sample injection respectively, near the detection limit, that is, when S / N=3, the detection concentration is determined to be 0.00001mg / ml, indicating that the detection limit of this method is very low, and it is a gas phase 10-100 times that of chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com