Thermal non-contact voltage and non-contact current devices

A non-contact, measurement equipment technology, applied in non-contact circuit testing, voltage/current isolation, phase angle between voltage and current, etc., can solve the problem that infrared imaging cannot quantify energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

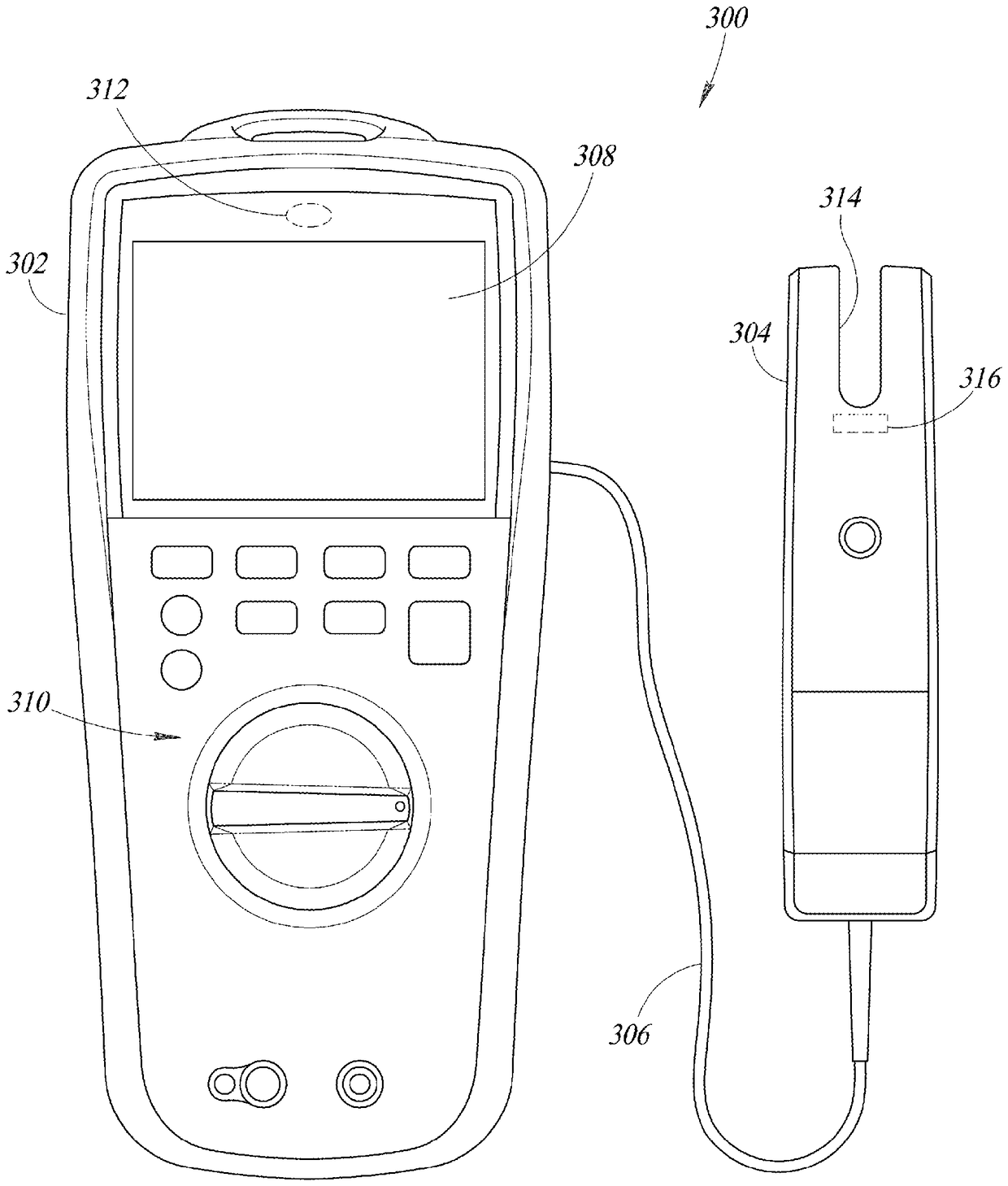

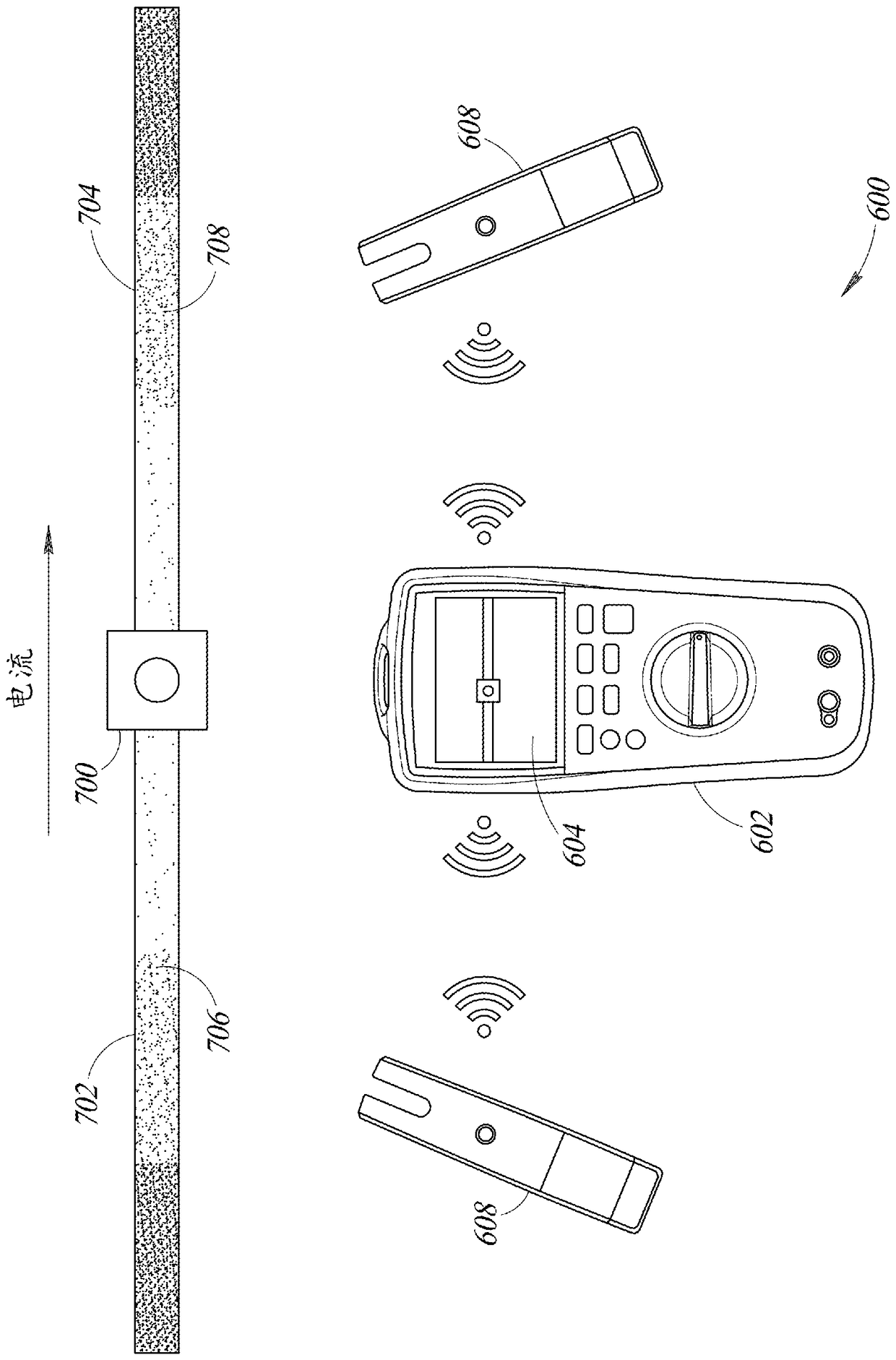

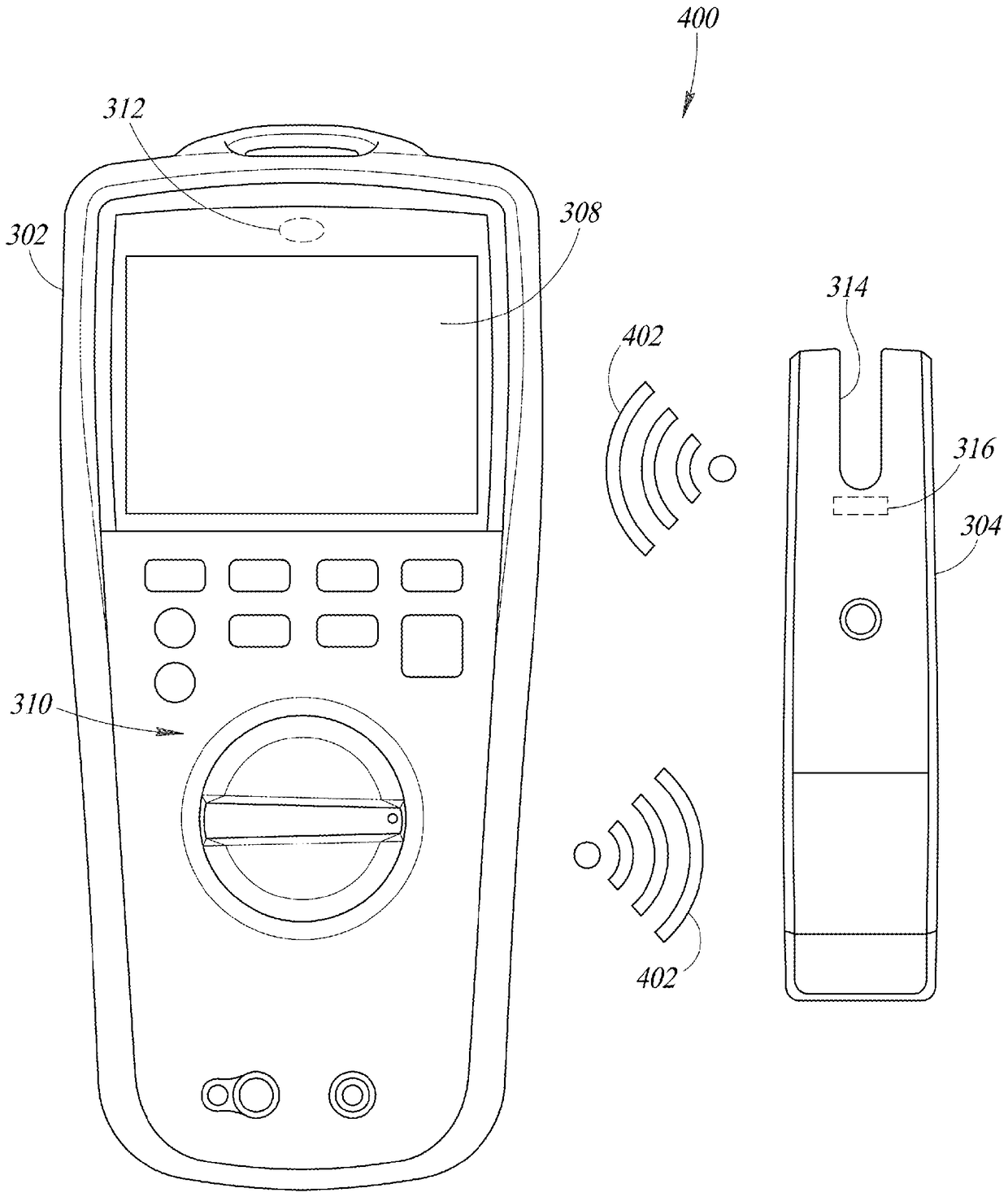

[0023] One or more implementations of the present disclosure provide systems and methods that provide thermal imaging and non-contact voltage or current measurement sensors to detect or measure anomalies in electrical circuits. Such systems and methods may be implemented in a single test device, or in a wired combination, or in wireless communication with multiple test devices and / or accessories, or with one or more additional devices such as mobile phones, tablets, A combination of personal computers (PCs), cloud-based servers, etc. is implemented.

[0024] In at least some implementations, a thermal imaging system or tool of a measurement device including an infrared sensor may first find and image one or more thermal anomalies in an object, such as an electrical circuit. A user or measurement device may then analyze the detected thermal patterns, which may indicate a localized high resistance electrical connection, or high resistance due to incorrect conductor or component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com