A method for reduce spherical defects in deep submicron photolithography process

A photolithography process and spherical defect technology, applied in photosensitive material processing, pattern surface photoengraving process, photoengraving process coating equipment, etc. , to ensure consistency, to ensure the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

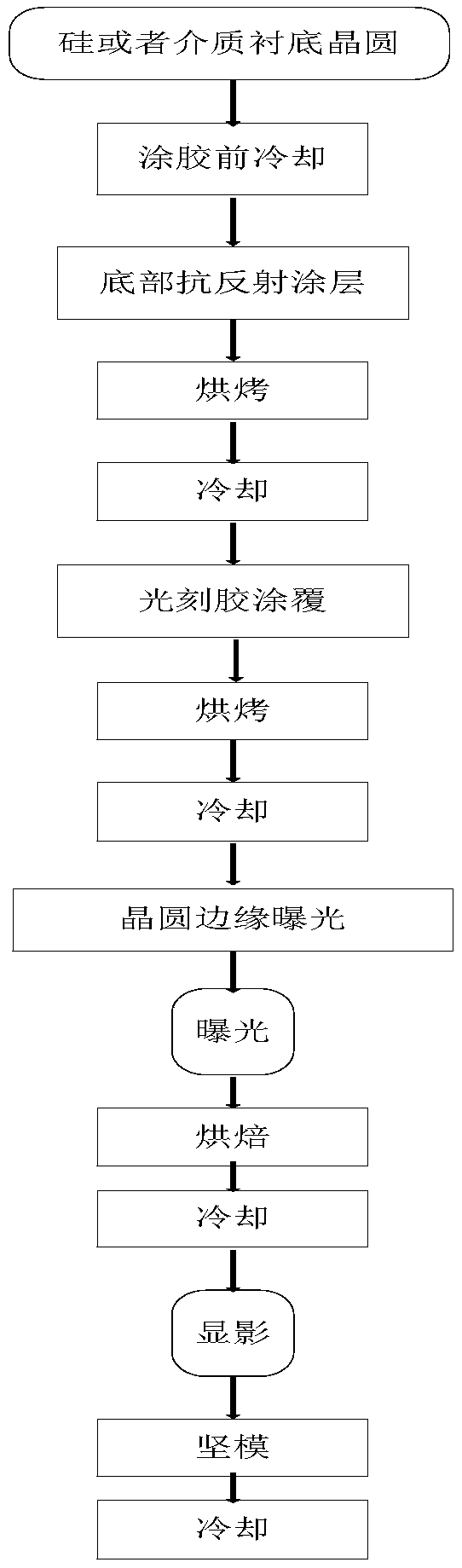

[0067] 1) Place the wafer on the 23°C cold plate in the gluing chamber of the gluing and developing all-in-one machine for cooling pretreatment before gluing, and the time is 60s;

[0068] 2) Coat the bottom anti-reflection coating on the wafer in the coating chamber and let it stand for 50s;

[0069] 3) Baking the finished wafer on a 180°C high-temperature hot plate for 60s to evaporate the solvent in the anti-reflective coating;

[0070] 4) Transfer the wafer to the cold plate to lower the temperature to room temperature to prepare for the next process;

[0071] 5) The required photoresist coating is carried out on the wafer, so that the graphics on the photoresist plate are printed into the film after exposure;

[0072] 6) Transfer the wafer to a 90°C low-temperature hot plate and bake for 60s to discharge the water vapor and other liquids in the adhesive layer;

[0073] 7) Transfer the wafer to a 23°C cold plate to cool to room temperature;

[0074] 8) Expose the photor...

Embodiment 2

[0082] Present embodiment is identical with embodiment 1 except step 2), and step 2) is in the present embodiment:

[0083] Coat the bottom anti-reflection coating on the wafer in the coating chamber and let it stand for 60s.

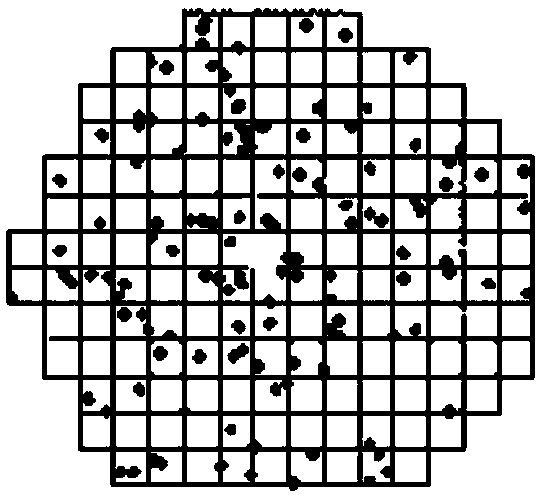

[0084] The spherical defect analysis is carried out on the wafer completed by photolithography in this embodiment, and the spherical defect distribution results can be found in Figure 7 , Through the inspection of defects one by one, the number of spherical defects is significantly reduced compared with the original method, and the number of defects is about 2 to 3, which is acceptable for general semiconductor wafer manufacturing processes.

Embodiment 3

[0086] Present embodiment is identical with embodiment 1 except step 2), and step 2) is in the present embodiment:

[0087] Coat the bottom anti-reflection coating on the wafer in the coating chamber and let it stand for 70s.

[0088] The spherical defect analysis is carried out on the wafer completed by photolithography in this embodiment, and the spherical defect distribution results can be found in Figure 8 , Through checking the defects one by one, no spherical defects were found.

[0089] The experiment was repeated 10 times, and the completed wafer was scanned for defects and reviewed for defects, and no spherical defects were found. in, Figure 9 It is a schematic diagram of the defect distribution of two of them extracted, Figure 9 (a) Schematic diagram of the distribution of spherical defects in the first experiment, Figure 9 (b) is a schematic diagram of the distribution of spherical defects in the eighth experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com