Color toner prepared by emulsion polymerization-coagulation one-step method and method thereof

A color toner and emulsion technology, which is applied in the fields of instruments, developers, optics, etc., can solve the problems of long toner preparation time, complex process, high energy consumption, etc., and achieve the goals of shortening the preparation time, increasing the coagulation rate, and high conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

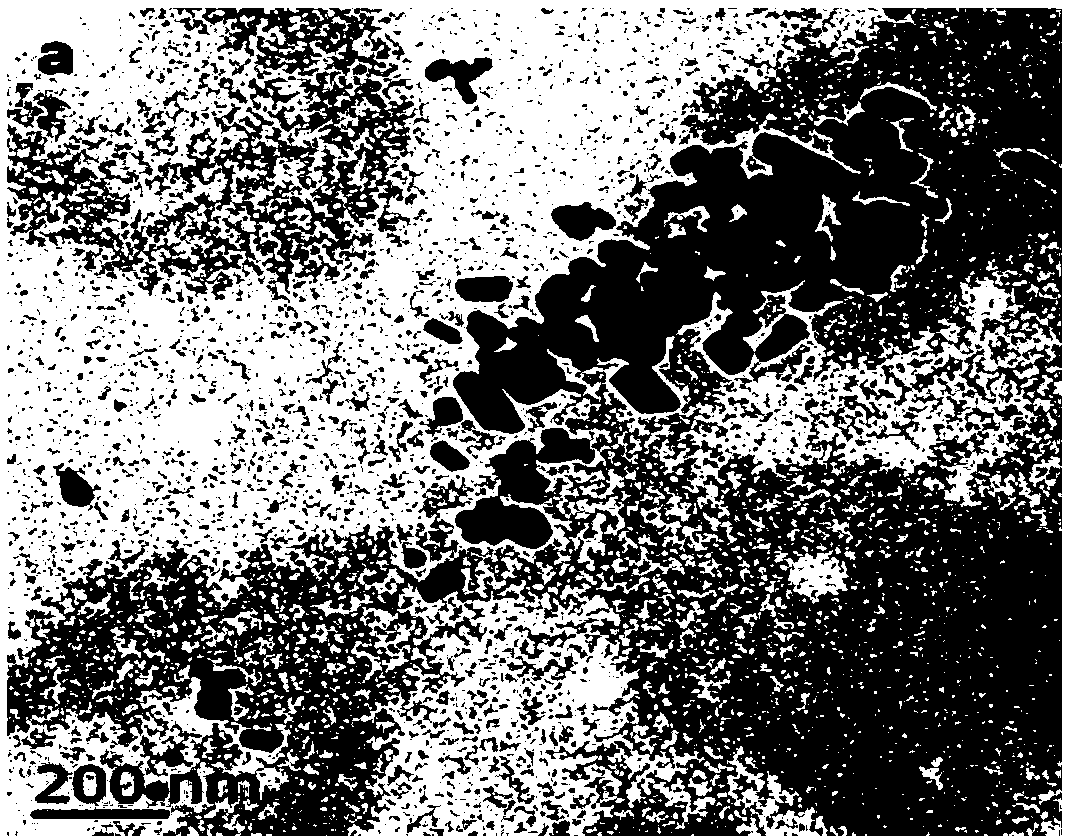

[0053] Step 1: Preparation of organic pigment, wax, and charge regulator dispersion: 7 parts of organic pigment blue RB15:3, 20 parts of oxidized polyethylene wax emulsion, 1 part of charge regulator, 8 parts of TX-100, 1.5 parts of SDS Put it into the container, add 650 parts of deionized water, ultrasonically disperse for 10 minutes, then transfer to a ball mill, and ball mill for 8 hours at a speed of 580r / min to obtain a dispersion with uniform particle size, good dispersibility, and no agglomeration. The TEM image of the morphology is shown in figure 1 shown;

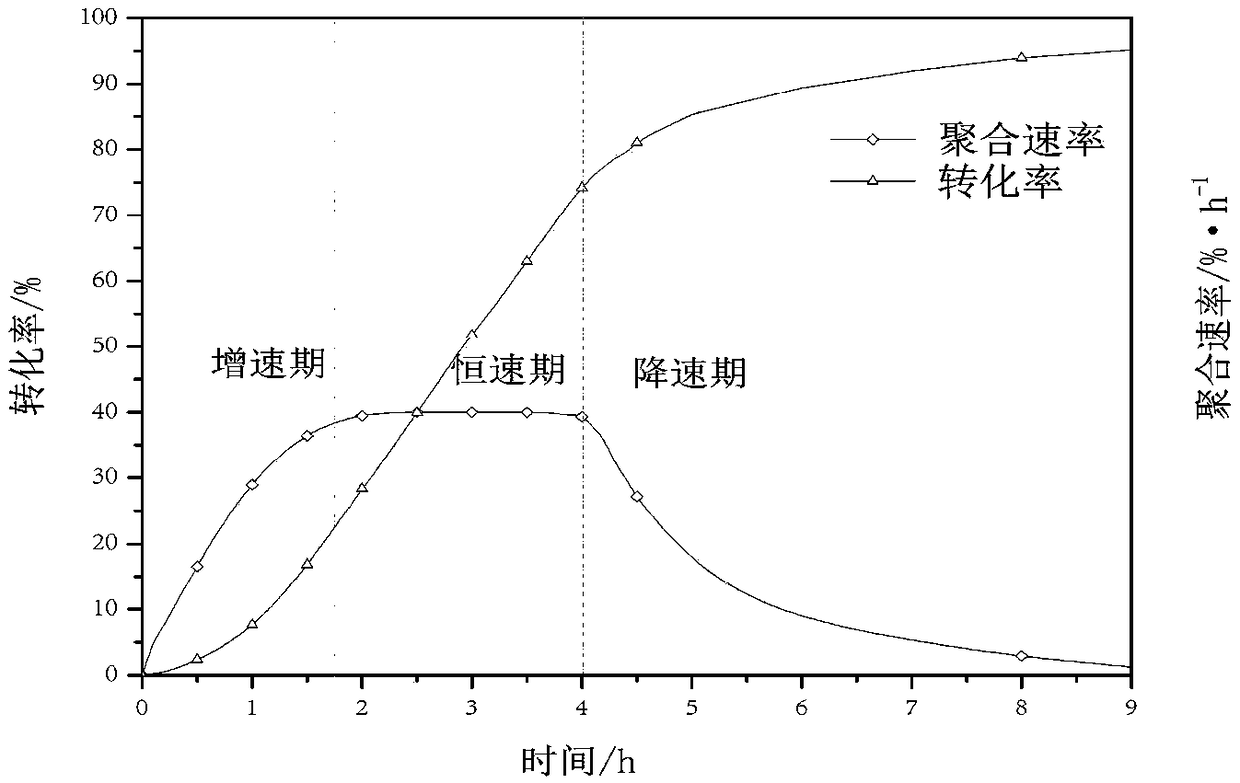

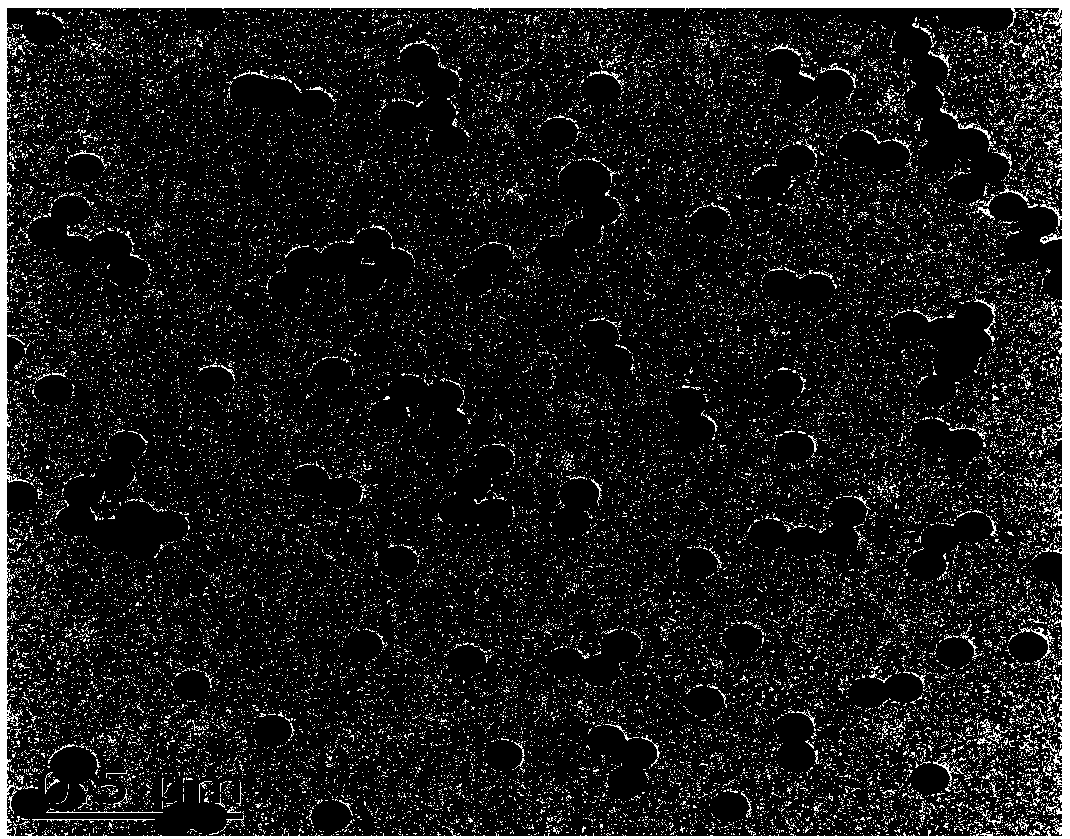

[0054] Step 2: Preparation of resin-coated pigment, wax and charge agent composite latex particles: transfer the dispersion prepared in step (1) to the reactor, add 75 parts of styrene and 20 parts of butyl acrylate into the container, and ultrasonically Mix evenly, and then add dropwise to the dispersion in the reactor within 40 minutes under stirring at a rotation speed of 450 rpm. Dissolve 3 parts of water-sol...

Embodiment 2

[0062] Step 1: Preparation of organic pigment, wax, and charge regulator dispersion: Add 5 parts of organic pigment yellow RY17, 15 parts of oxidized polyethylene wax emulsion, 0.5 parts of charge regulator, 5 parts of TX-100, and 1 part of SDS into In the container, add 600 parts of deionized water, ultrasonically disperse for 8 minutes, then transfer to a ball mill, and ball mill for 7 hours at a speed of 580 rpm to obtain a dispersion with uniform particle size, good dispersibility, and no agglomeration;

[0063] Step 2: Preparation of resin-coated pigment, wax and charge regulator composite latex particles: transfer the dispersion prepared in step (1) to the reactor; add 65 parts of styrene and 15 parts of butyl acrylate into the container , ultrasonically mixed evenly, and then added dropwise to the dispersion in the reactor within 35 minutes under stirring at a rotational speed of 400 rpm. Dissolve 2 parts of water-soluble initiator KPS in 90 parts of deionized water, af...

Embodiment 3

[0068] Step 1: Preparation of organic pigment, wax, and charge regulator dispersion: 3 parts of organic pigment red PR48:2, 10 parts of oxidized polyethylene wax emulsion, 0.2 part of charge regulator, 2 parts of TX-100, 0.4 part of SDS Add to the container, add 500 parts of deionized water, ultrasonically disperse for 5 minutes, then transfer to a ball mill, and ball mill at 580rpm for 4 hours to obtain a dispersion with uniform particle size, good dispersibility, and no agglomeration;

[0069] Step 2: Preparation of resin-coated pigment, wax and charge regulator composite latex particles: transfer the dispersion prepared in step (1) to the reactor; add 55 parts of styrene and 10 parts of butyl acrylate into the container, Ultrasonic mixing is uniform, and then it is added dropwise to the dispersion in the reactor within 30 minutes under stirring at a rotational speed of 350 rpm. Dissolve 1.5 parts of water-soluble initiator KPS in 80 parts of deionized water, and slowly drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com