An electrolyte additive of a high-pressure solid lithium iron phosphate battery and an electrolyte containing the additive

An electrolyte additive, lithium iron phosphate technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem of affecting the rate performance, discharge capacity and service life of lithium batteries, the limited ability to absorb organic electrolytes, and the inability to participate Improve the discharge rate characteristics, reduce the battery interface impedance, good thermal stability and chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

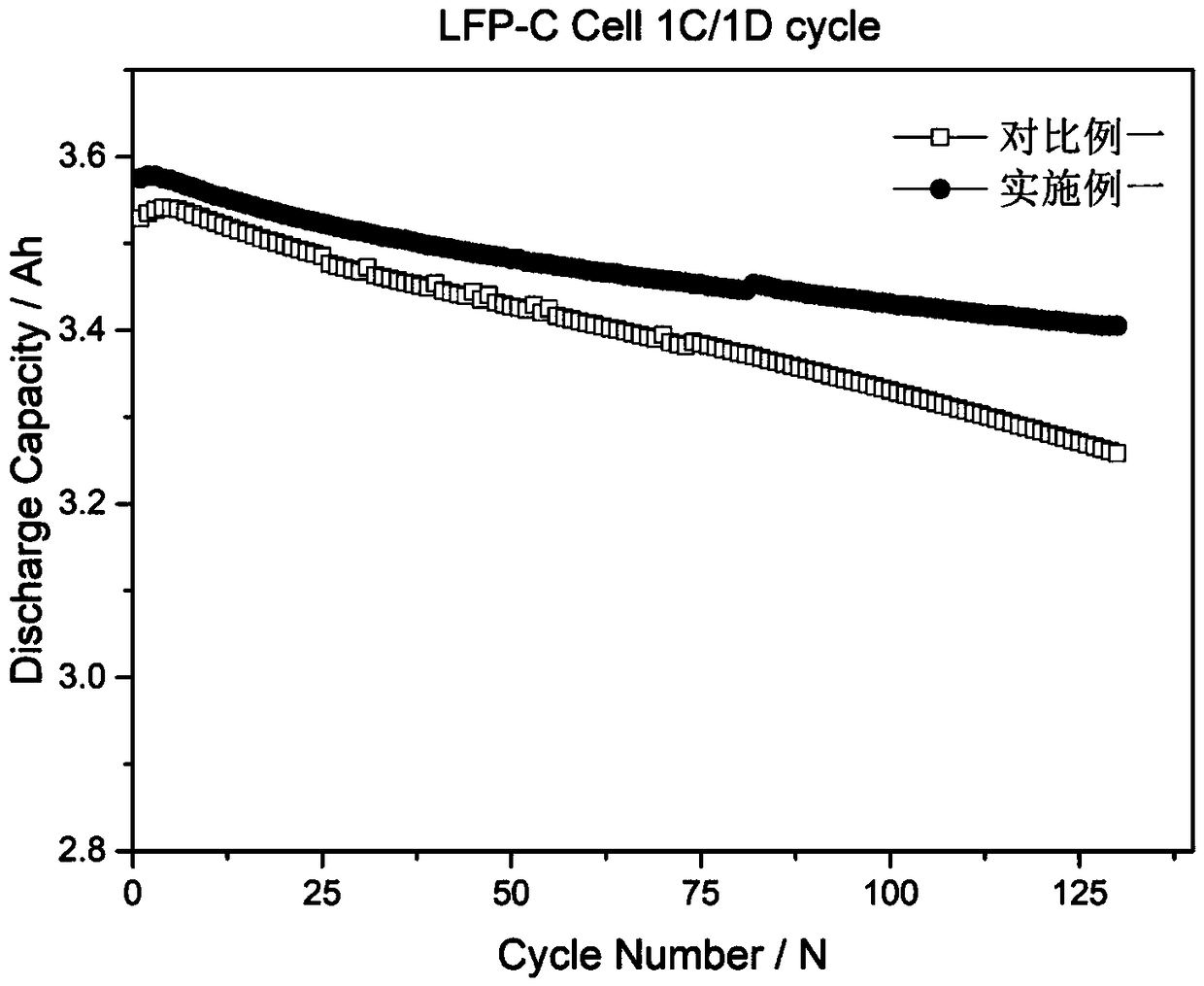

Embodiment 1

[0027] An electrolyte solution containing an electrolyte additive for a high-pressure lithium iron phosphate battery, the specific calculation formula of 100g electrolyte is: 25.65g ethylene carbonate, 59.85g methyl ethyl carbonate, 0.5g C 9 h 19 C 6 h 4 O(CH 2 CH 2 O) 6 -PO(OH) 2 , 1.5g vinylene carbonate, 12.5g LiPF 6 ; The specific preparation method is: prepare the electrolyte solution in a BRAUN glove box, the glove box is filled with argon gas with a purity of 99.999%, the moisture in the glove box is controlled at ≤ 5ppm, and the temperature is at room temperature; 25.65g ethylene carbonate, 59.85g carbonic acid Methyl ethyl ester, 0.5g C 9 h 19 C 6 h 4 O(CH 2 CH 2 O) 6 -PO(OH) 2 , 1.5g vinylene carbonate and mix evenly, then add 12.5gLiPF 6 Mix well to form 1.0mol / L LiPF 6 a.

Embodiment 2

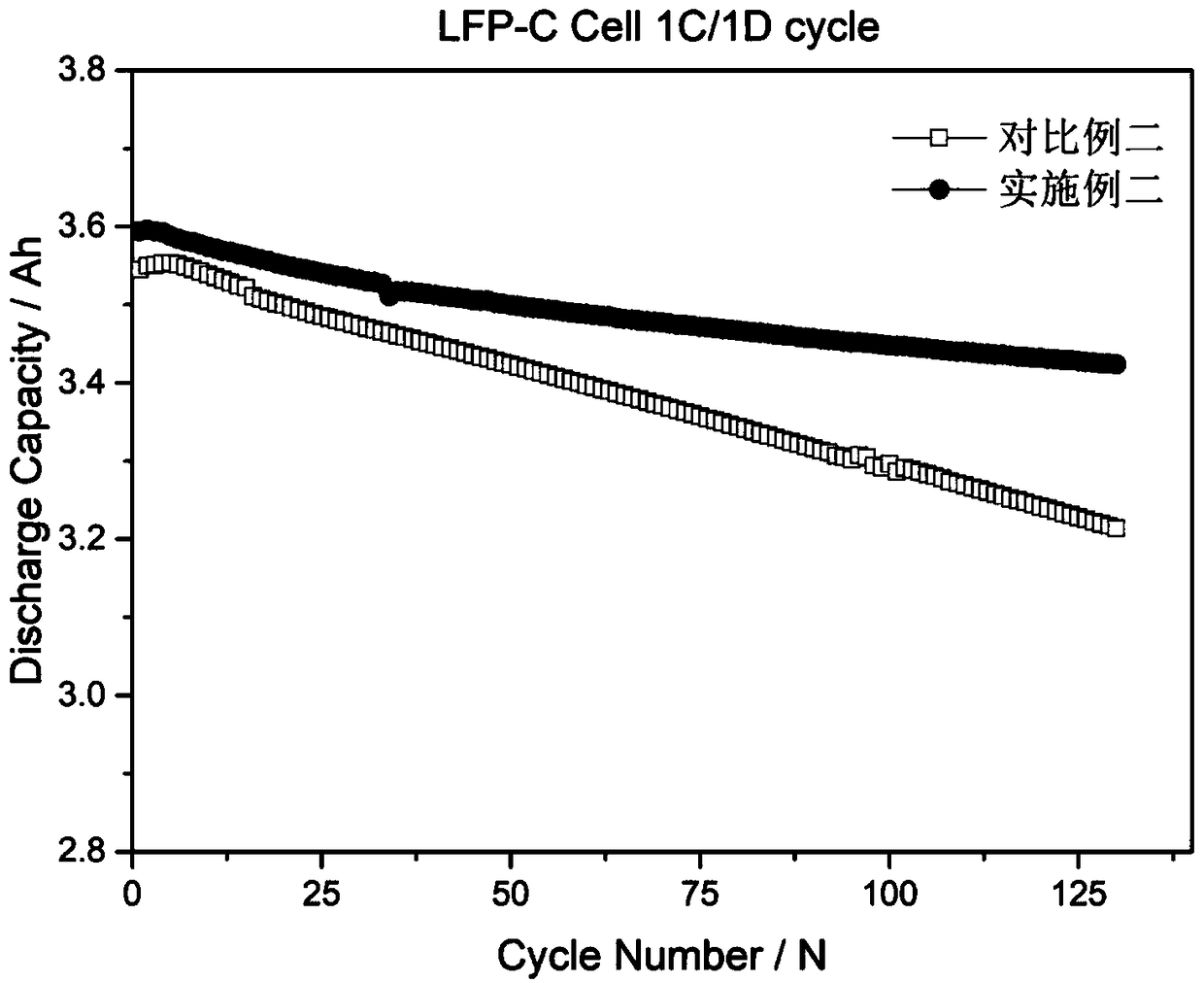

[0031]An electrolyte solution containing an electrolyte additive for a high-pressure lithium iron phosphate battery, the specific calculation formula of 100g electrolyte is: 24.75g ethylene carbonate, 33.0g methyl ethyl carbonate, 24.75g dimethyl carbonate, 0.5g C 9 h 19 C 6 h 4 O(CH 2 CH 2 O) 8 -PO(OH) 2 , 2.5g vinylene carbonate, 14.5g LiPF 6 ; The specific preparation method is: prepare the electrolyte solution in a BRAUN glove box, the glove box is filled with argon gas with a purity of 99.999%, the moisture in the glove box is controlled at ≤ 5ppm, and the temperature is at room temperature; 24.75g ethylene carbonate, 33.0g carbonic acid Methyl ethyl ester, 24.75g dimethyl carbonate, 0.5g C 9 h 19 C 6 h 4 O(CH 2 CH 2 O) 8 -PO(OH) 2 , 2.5g vinylene carbonate and mix evenly, then add 14.5g LiPF 6 Mix well to form 1.2mol / L LiPF 6 a.

Embodiment 3

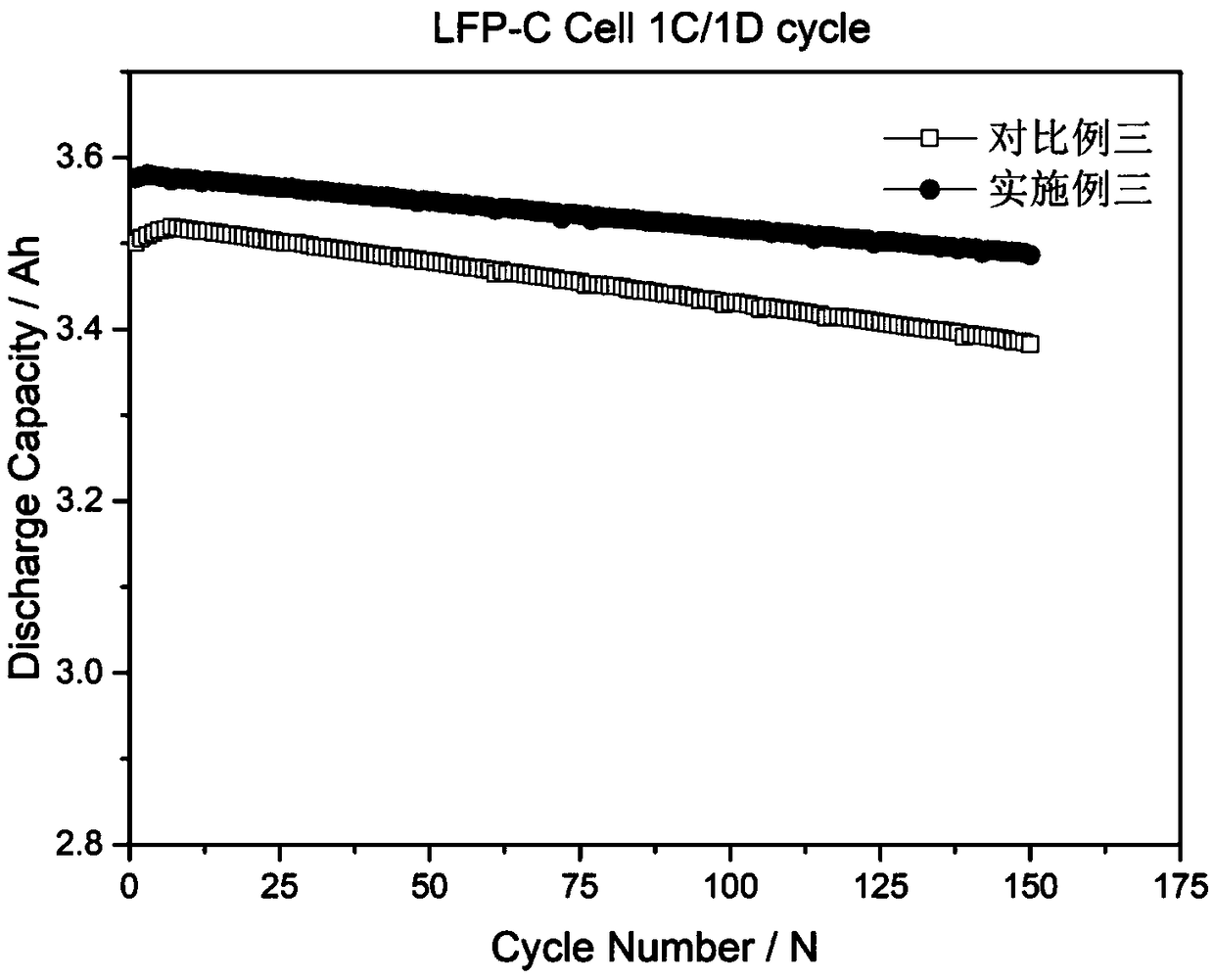

[0035] An electrolyte solution containing an electrolyte additive for a high-pressure lithium iron phosphate battery, the specific calculation formula of 100g electrolyte is: 24.6g ethylene carbonate, 41.0g methyl ethyl carbonate, 16.4g diethyl carbonate, 1.5g C 9 h 19 C 6 h 4 O(CH 2 CH 2 O) 12 -PO(OH) 2 , 1.0g vinylene carbonate, 1.0g 1,3-propane sultone, 12.5g LiPF 6 and 2.0gLiTFSI; the specific preparation method is: prepare the electrolyte solution in the BRAUN glove box, the glove box is filled with argon gas with a purity of 99.999%, the moisture in the glove box is controlled at ≤ 5ppm, and the temperature is at room temperature; 24.6g ethylene carbonate, 41.0g ethyl methyl carbonate, 16.4g diethyl carbonate, 1.5g C 9 h 19 C 6 h 4 O(CH 2 CH 2 O) 12 -PO(OH) 2 , 1.0g vinylene carbonate, 1.0g 1,3-propane sultone mixed evenly, then add 12.5gLiPF 6 Mix well with 2.0gLiTFSI to form 1.0mol / L LiPF 6 and a mixed electrolyte solution of 0.2mol / L LiTFSI.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com