Separator for electrochemical elements, and electrochemical element using same

一种电化学元件、隔离物的技术,应用在电气元件、电解电容器、电池组零部件等方向,能够解决阻碍密封等问题,达到故障少、内部短路故障率小、表面平滑性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

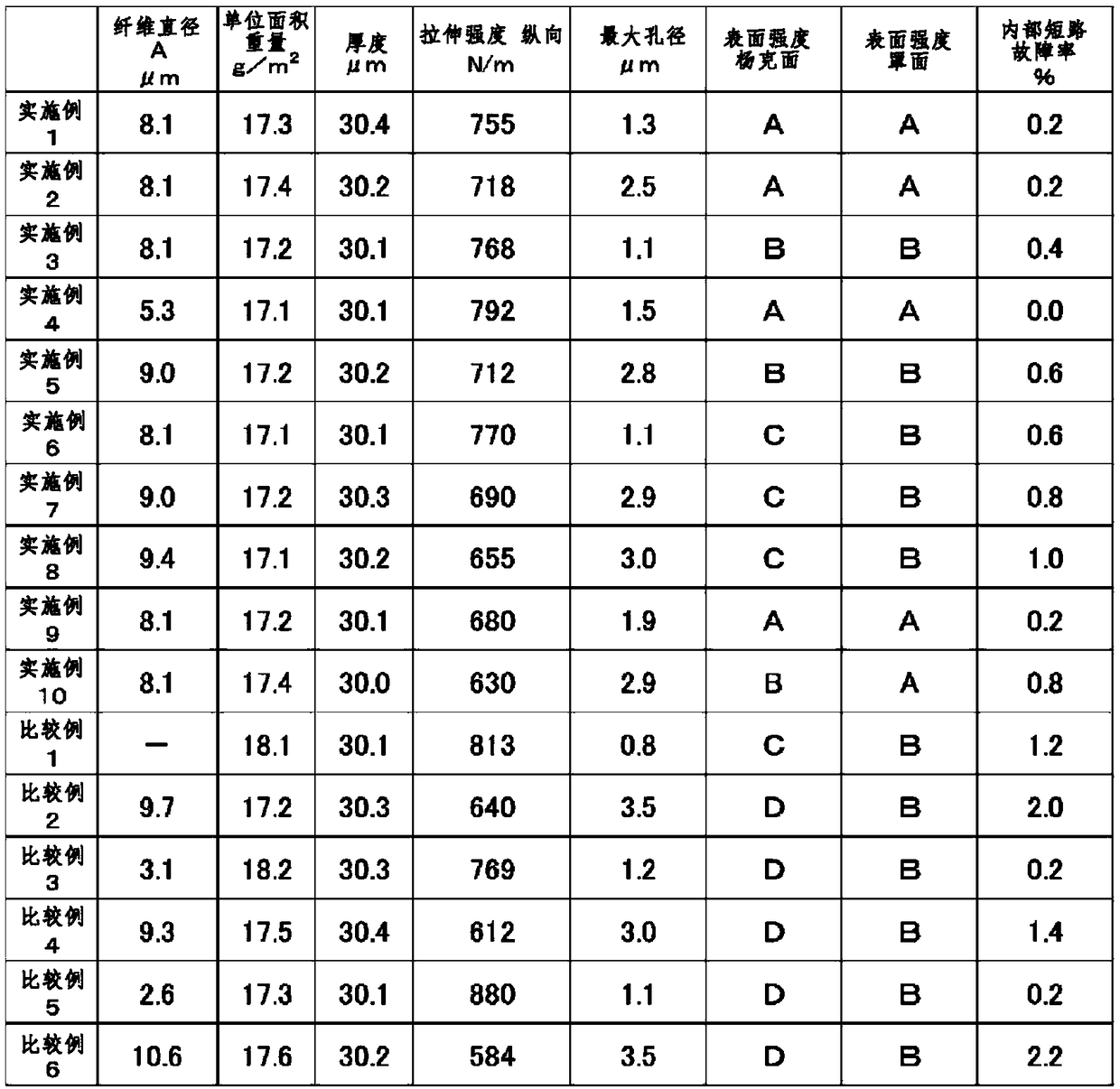

Embodiment 1

[0082] Mix 15 parts of rayon fibers with a fineness of 0.8 dtex and a fiber length of 3 mm and 85 parts of solvent-spun cellulose fibers with a beating degree of 90 ml by a modified method, and dissociate them in the water of a pulper, and use a stirrer to After stirring, a uniform raw material slurry (0.3% concentration) was prepared. The beaten solvent-spun cellulose fibers were obtained by finely refining solvent-spun cellulose fibers having a fiber diameter R of 10 μm and a fiber length of 4 mm. A wet-laid fiber web was obtained from the raw material slurry using an inclined short-wire paper machine. The wet fiber web was dried using a Yankee dryer (temperature 120° C.) and a hot air hood dryer (temperature 120° C.) installed on the upper surface of the Yankee dryer to obtain a dried fiber web. Thereafter, the dried web was subjected to a calender treatment using metal rolls and elastic rolls to obtain a basis weight of 17.3 g / m 2 , A spacer with a thickness of 30.4 μm. ...

Embodiment 2

[0084] The rayon fibers in Example 1 were set to 25 parts, and the solvent-spun cellulose fibers formed by beating were set to 75 parts, except that, the same method was used to obtain a weight per unit area of 17.4 g / m 2 , A spacer with a thickness of 30.2 μm.

Embodiment 3

[0086] The rayon fiber in Example 1 was set as 10 parts, and the solvent spinning cellulose fiber formed by beating was set as 90 parts, except that, the same method was used to obtain a weight per unit area of 17.2 g / m 2 , A spacer with a thickness of 30.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com