Method and device for extracting caprolactam crude oil

A caprolactam, crude oil technology, applied in the separation/purification of lactam, chemical instruments and methods, liquid solution solvent extraction, etc., can solve the requirements of motor shaft wear and sealing, low extraction and separation efficiency, and large power consumption of rotary disk towers, etc. problems, to achieve the effect of loose sealing conditions, avoiding wall flow and short-circuit flow, and saving manpower, material resources and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Implementation process:

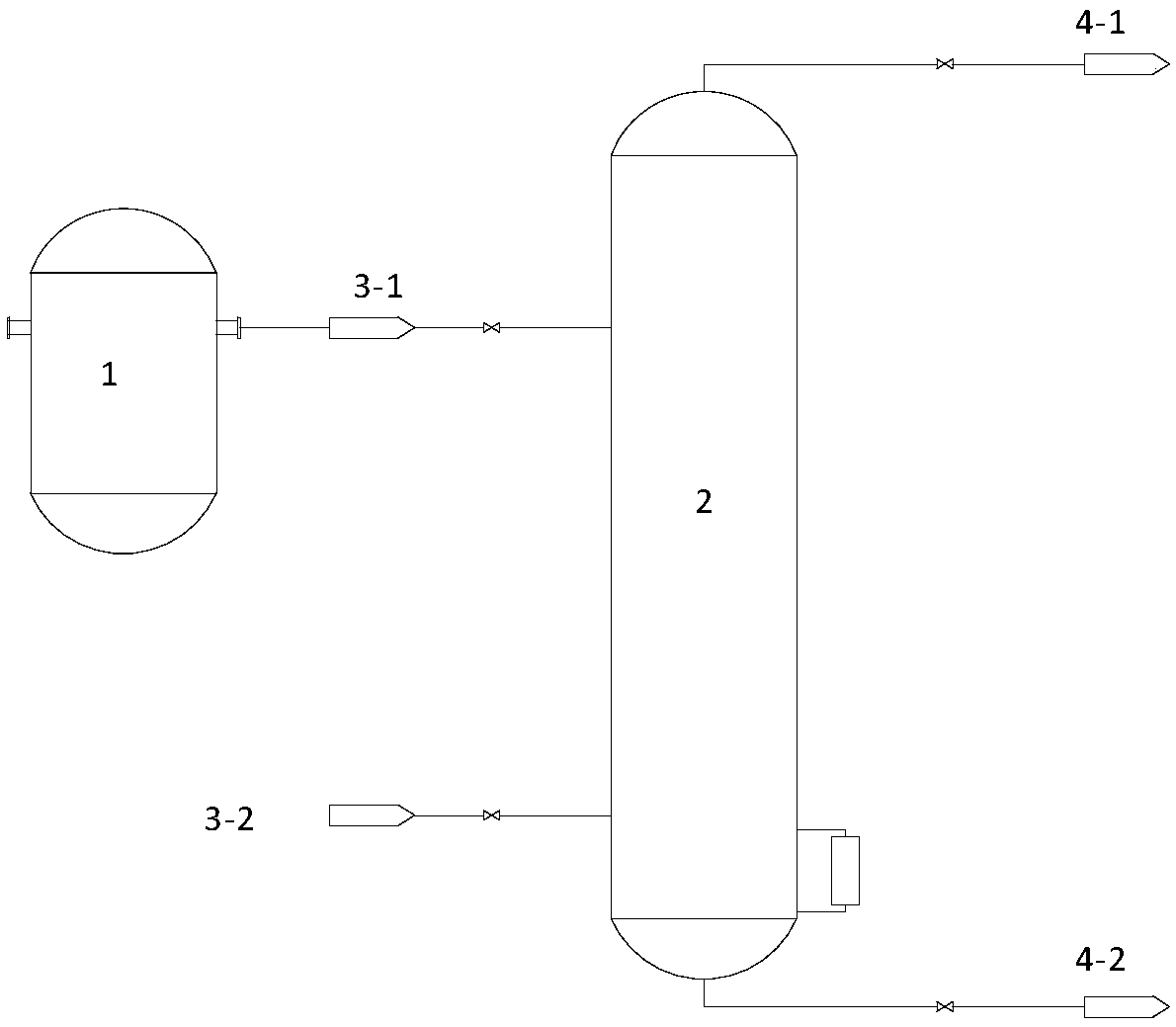

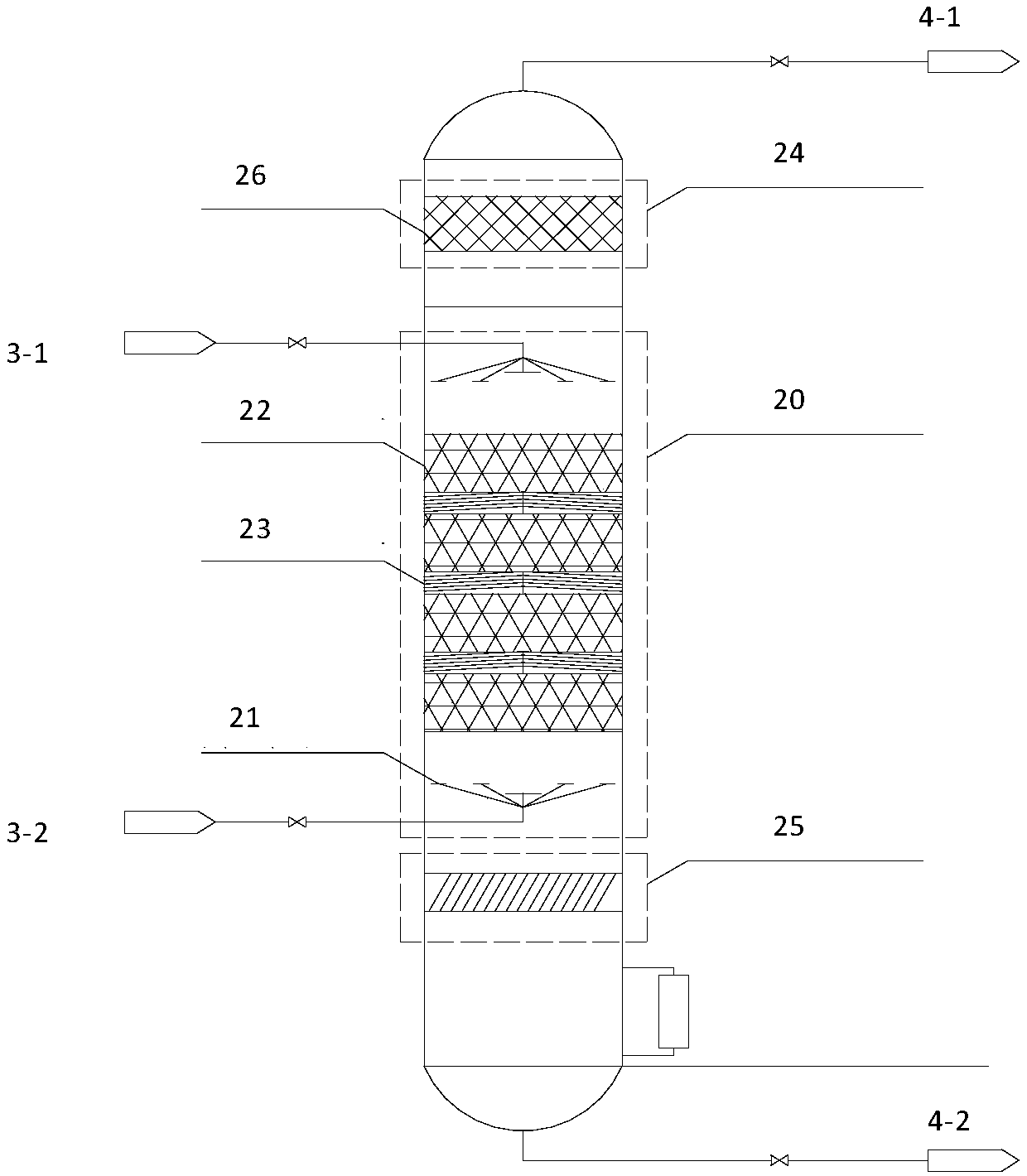

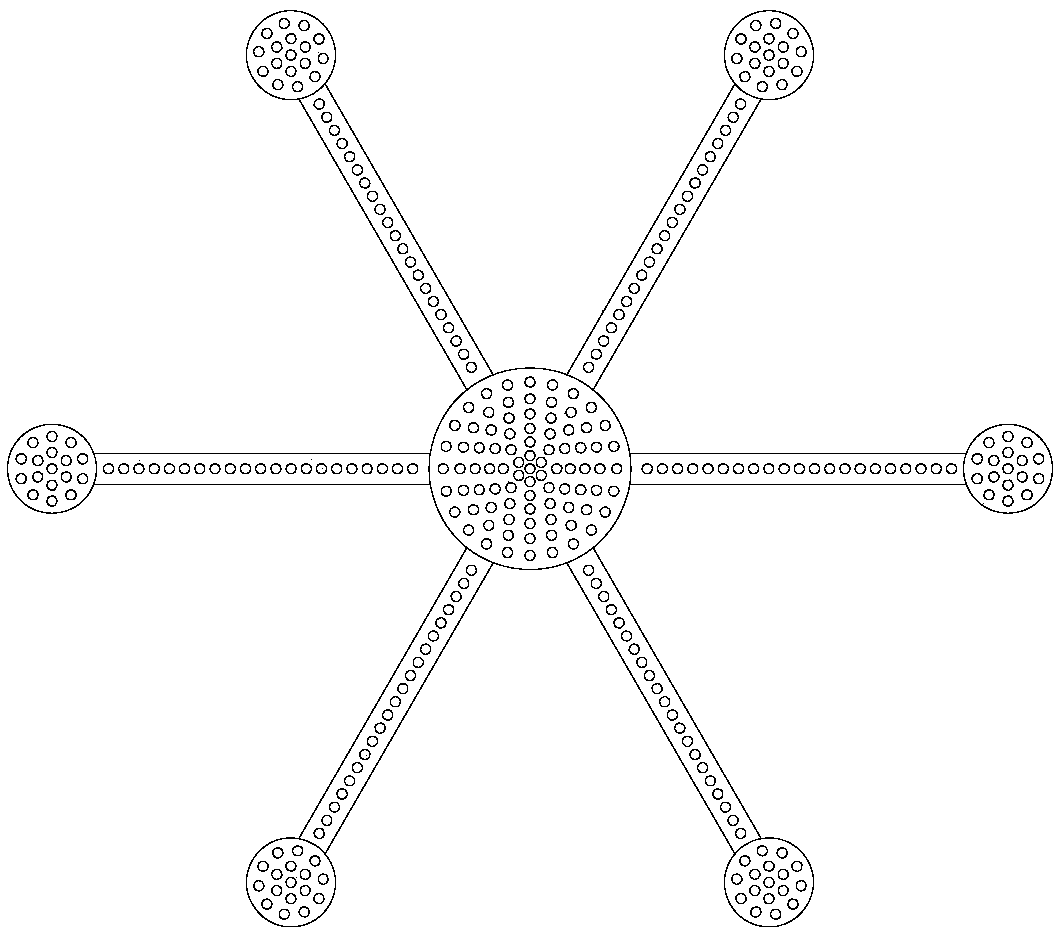

[0065] A certain chemical plant uses the novel caprolactam extraction device of the present invention, and the schematic diagram of the device is as follows figure 1 shown. The device consists of two parts: a filter and an extraction tower. Wherein the extraction tower includes an extraction section and a separation section; the extraction section is used to extract the caprolactam crude oil with benzene, including a distributor, a mass transfer packing and a redistributor, and an inlet for the caprolactam crude oil and an inlet for benzene ; The separation section is used to separate the extracted benzene ethyl alcohol and the raffinate, including a separation packing strengthening separation section and a gravity sedimentation separation section, as well as an outlet for the benzene ethyl alcohol outlet and an outlet for the raffinate. Filling starts from the top of the benzene phase distributor, and the filling is installed in sections, ea...

Embodiment 2

[0069] Implementation process:

[0070] A certain chemical plant uses the novel caprolactam extraction device of the present invention, and the schematic diagram of the device is as follows figure 1 shown. The device consists of two parts: a filter and an extraction tower. Wherein the extraction tower includes an extraction section and a separation section; the extraction section is used for the extraction of the caprolactam crude oil by benzene, and the extraction section of the caprolactam crude oil includes a distributor, a mass transfer packing and a redistributor, and an inlet for the caprolactam crude oil and an inlet for benzene; the separation section is used to separate the extracted benzene ethyl alcohol and the raffinate, including a separation packing strengthening separation section and a gravity sedimentation separation section, and one for the benzene ethyl alcohol outlet and one for the residual liquid liquid outlet. Filling starts from the top of the benzen...

Embodiment 3

[0074] Implementation process:

[0075] A certain chemical plant uses the novel caprolactam extraction device of the present invention, and the schematic diagram of the device is as follows figure 1shown. The device consists of two parts: a filter and an extraction tower. Wherein the extraction tower includes an extraction section and a separation section; the extraction section is used for the extraction of the caprolactam crude oil by benzene, and the extraction section of the caprolactam crude oil includes a distributor, a mass transfer packing and a redistributor, and an inlet for the caprolactam crude oil and an inlet for benzene; the separation section is used to separate the extracted benzene ethyl alcohol and the raffinate, including a separation packing strengthening separation section and a gravity sedimentation separation section, and one for the benzene ethyl alcohol outlet and one for the residual liquid liquid outlet. Filling starts from the top of the benzene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com