Mechanical low-frequency vibration drilling device

A low-frequency vibration, mechanical technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problem of inability to achieve high-speed rotational axial vibration, inability to achieve quick adjustment of amplitude, and limitations Vibration hole making technology and other issues to achieve the effect of improving cooling and lubrication effects, solving the problem of chip breaking and chip removal, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

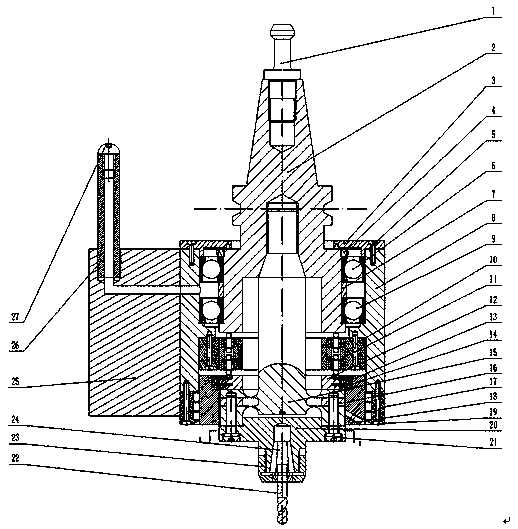

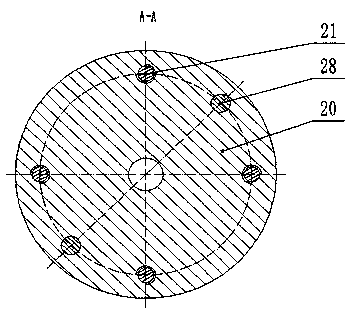

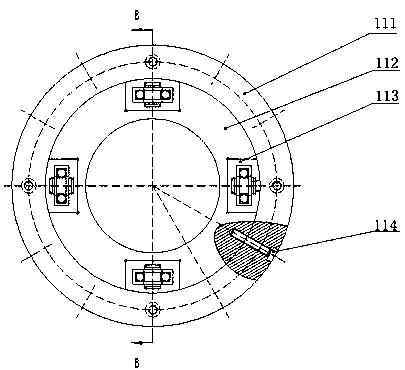

[0022] Example: see Figure 1-Figure 4 , in the figure, 1-pull stud, 2-end cam with tapered shank, 3-sealing cover ring, 4-compression nut, 5-screw, 6-angular contact ball bearing, 7-spacer, 8-device shell, 9-angular contact ball bearing, 10-screw, 11-fixed disc, 12-driven cam, 13-female key, 14-screw, 15-annular flexible hinge, 16-supporting half disc, 17-sealing ring , 18-adjusting nut, 19-screw, 20-vibration output rod, 21-screw, 22-drill, 23-nut, 24-spring collet, 25-shell fixing handle, 26-shell fixing rod, 27-cap, 28-location pin, 111-fixed disc inner ring, 112-fixed disc inner ring, 113-slider, 1131-slider body, 1132-support roller bearing, 1133-snap ring, 1134-support shaft, 114-screw.

[0023] A mechanical low-frequency vibration drilling device of the present invention includes six components such as a device housing 8, a tapered shank end cam 2, a driven end cam 12, a fixed disc 11, an annular flexible hinge 15 and a vibration output rod 20.

[0024] The device ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com