Modified m-cresol-phenol-formaldehyde resin, preparation method and rubber composition modified from modified m-cresol-phenol-formaldehyde resin

A technology of rubber composition and formaldehyde resin, which is applied in the field of rubber processing aids, can solve complex and other problems, and achieve the effects of improving storage performance, improving water resistance, and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

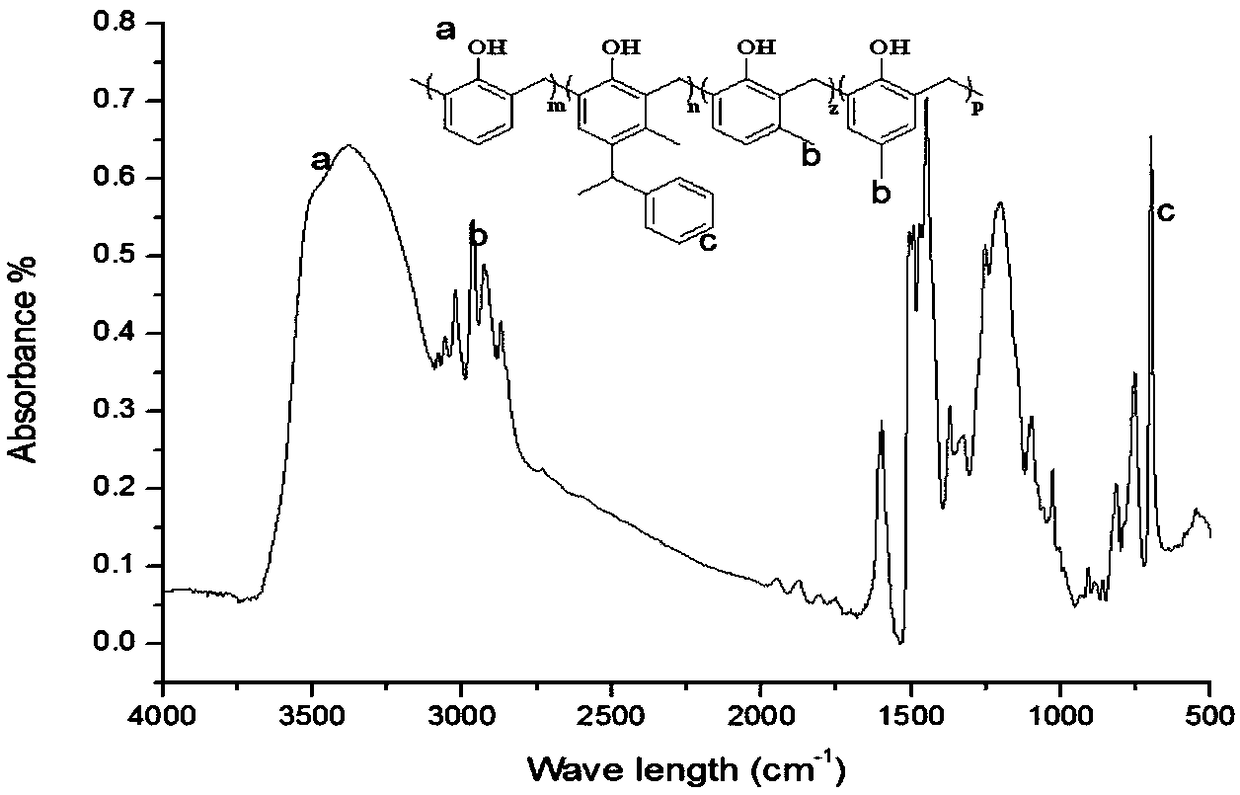

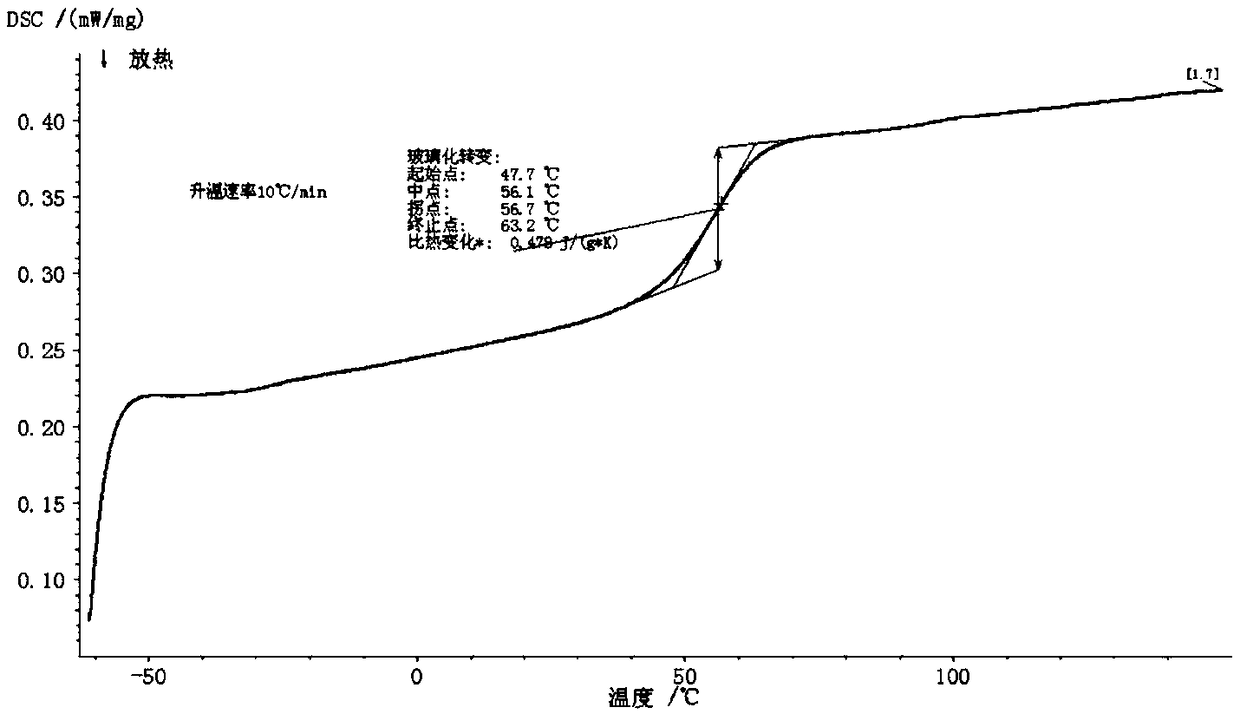

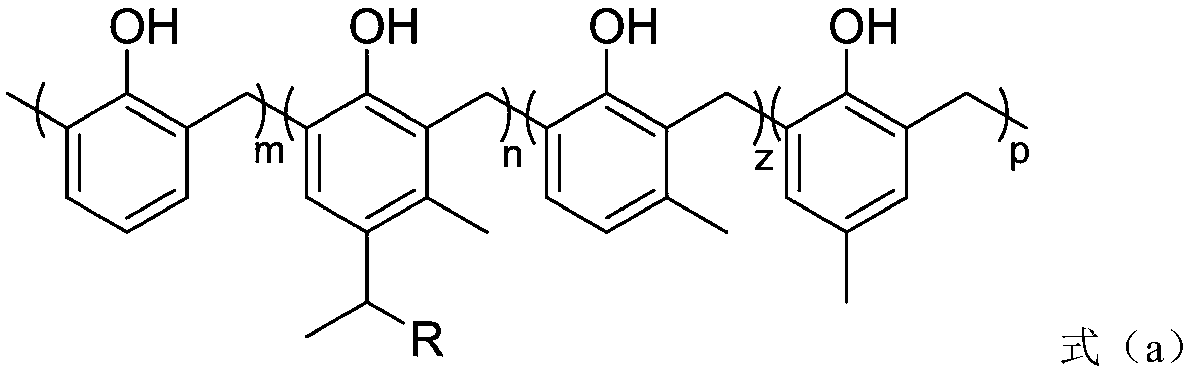

Embodiment 1

[0059] Add m-cresol 88g (0.8mol) and p-toluenesulfonic acid 2.9g to a 1L four-necked round-bottom flask equipped with stirring, temperature control, reflux condenser and constant pressure dropping funnel, and heat to 130°C, drop by drop Styrene 74.9 (0.72mol), after adding dropwise, keep warm for 90min, then add 94g (1mol) of phenol, then cool down to 100°C, add 103.0g of 37% formaldehyde (1.22mol) dropwise, keep warm for 90min after dropping, heat up to normal pressure Distill to 160°C, and distill at -0.08mpa for 60min under reduced pressure to obtain 258g of modified m-cresol-phenol-formaldehyde resin with a softening point of 105°C.

Embodiment 2

[0061] Add cresol 176g (1.6mol) in the 1L four-neck round-bottomed flask that is equipped with stirring, temperature control, reflux condenser and constant pressure dropping funnel, wherein m-cresol content is 70% and p-toluenesulfonic acid 1.1g, 1.1g of oxalic acid, heated to 130°C, added dropwise 108.2 (1.04mol) of styrene, kept warm for 90 minutes after the dropwise addition, then added 94g (1mol) of phenol, cooled to 100°C, then added dropwise 155.3g of 37% formaldehyde ( 1.87mol), after the dropwise addition, keep warm for 90min, heat up and distill at normal pressure to 160°C, and distill under reduced pressure at -0.08mpa for 60min to obtain 370g of modified m-cresol-phenol-formaldehyde resin with a softening point of 95°C.

Embodiment 3

[0063] Add m-cresol 132g (1.2mol) in a 1L four-neck round bottom flask equipped with stirring, temperature control, reflux condenser and constant pressure dropping funnel, wherein m-cresol content is 99.5% and p-toluenesulfonic acid 1.36g Heat to 130°C, add styrene 114.4 (1.1mol) dropwise, keep the temperature for 90 minutes after the dropwise addition, then add 94g (1mol) phenol, cool down to 100°C, then add 127.8g of 37% formaldehyde (1.54mol) dropwise, After the dropwise addition, keep the temperature for 90 minutes, raise the temperature and distill to 160°C under normal pressure, and then distill under reduced pressure at -0.08mpa for 60 minutes to obtain 342g of modified m-cresol-phenol-formaldehyde resin with a softening point of 98°C.

[0064] The specific relevant performance tests are as follows:

[0065] (1) The results of free phenol content are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com