Method for preparing high-refractive index nano-composite silicone encapsulation adhesive

A technology of nanocomposite and encapsulating adhesive materials, which is applied in the field of LED packaging and optical material preparation, and can solve the problems of particle reunion compatibility, small particle size of nano oxide particles, and difficulty in agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 37.04 g of zirconium n-propoxide, 23.56 g of acetic acid, and 50 g of OE-6636A glue in a beaker to dissolve with 100 ml of solvent, and control the temperature of the solution at about 0°C;

[0035] 2) Measure 4.10 g of water and dissolve it with 4 ml of solvent in a beaker, and control the temperature of the solution at about 0°C;

[0036] 3) Simultaneously send the solutions in the two beakers into the high gravity reactor, pass circulating water into the reactor, adjust the system temperature to a preset temperature, control the reactor speed to 500 rpm, and the circulation time is 10 minutes;

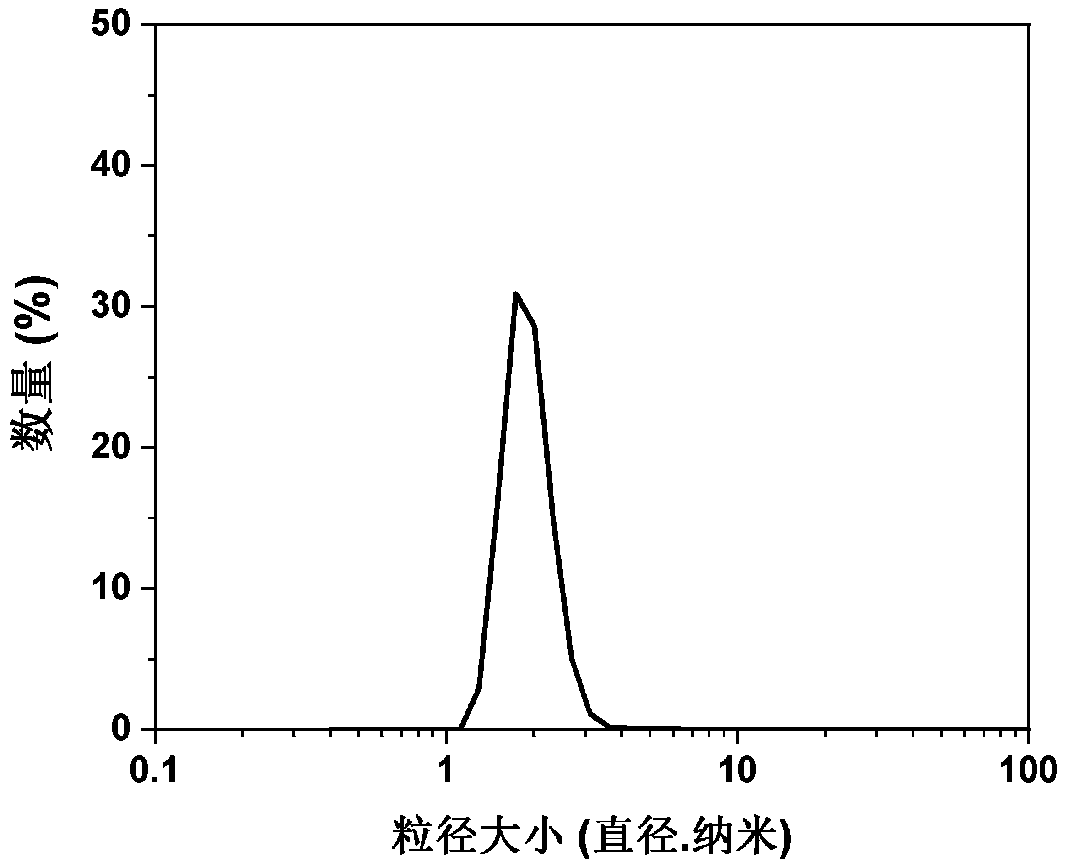

[0037] 4) The resulting solution was evaporated under reduced pressure at 50°C for 30 minutes, and 50 grams of OE-6636B glue was added. After testing, the particle size of nano-zirconia uniformly dispersed in silica gel is 2 nanometers. The film is prepared by spin coating (4000 rpm, 15 seconds), and cured at 100 degrees for 1.5 hours. The composite packaging adhesive has ...

Embodiment 2

[0039] 1) Weigh 0.3704 g of tetraisopropyl titanate, 0.2356 g of acetic acid and 0.5 g of OE-6636A glue in a beaker and dissolve with 100 ml of solvent, and control the temperature of the solution at 0°C

[0040] about;

[0041] 2) Measure 0.0410 g of water and dissolve it with 4 ml of solvent in a beaker, and control the temperature of the solution at about 0°C;

[0042] 3) Simultaneously send the solutions in the two beakers into the high gravity reactor, pass circulating water into the reactor, adjust the system temperature to a preset temperature, control the reactor speed to 500 rpm, and the circulation time is 10 minutes;

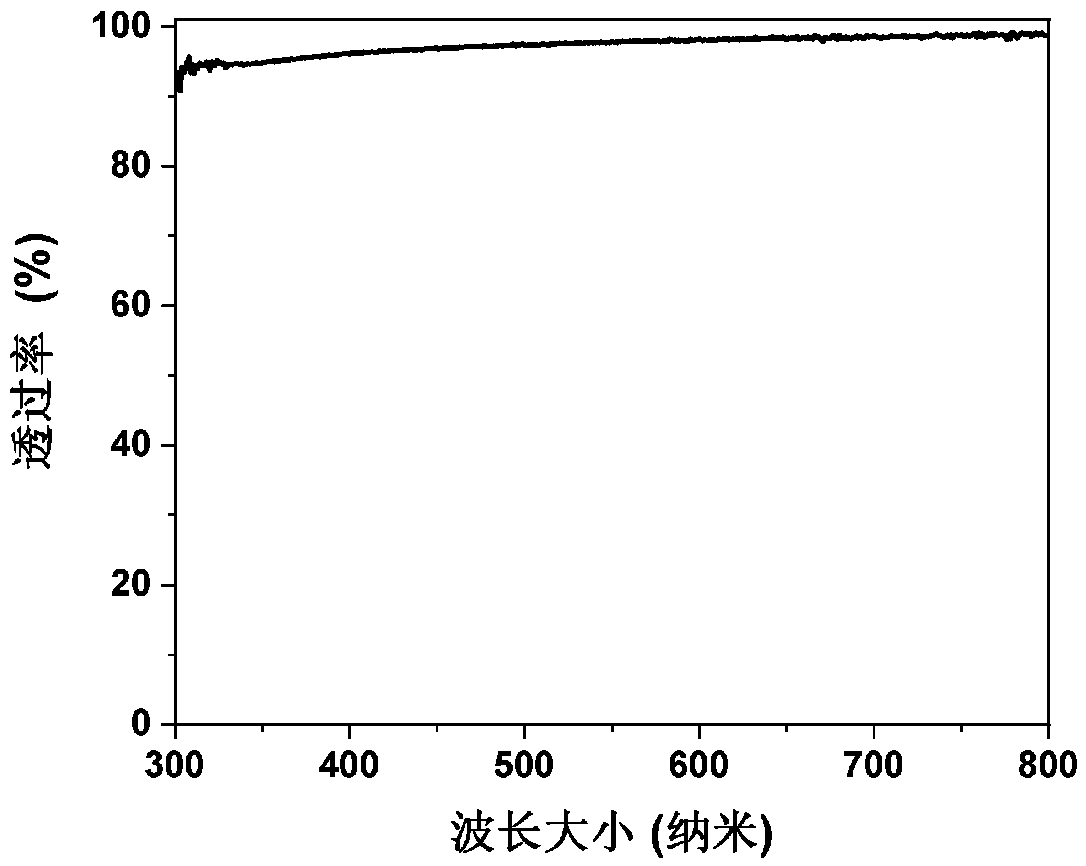

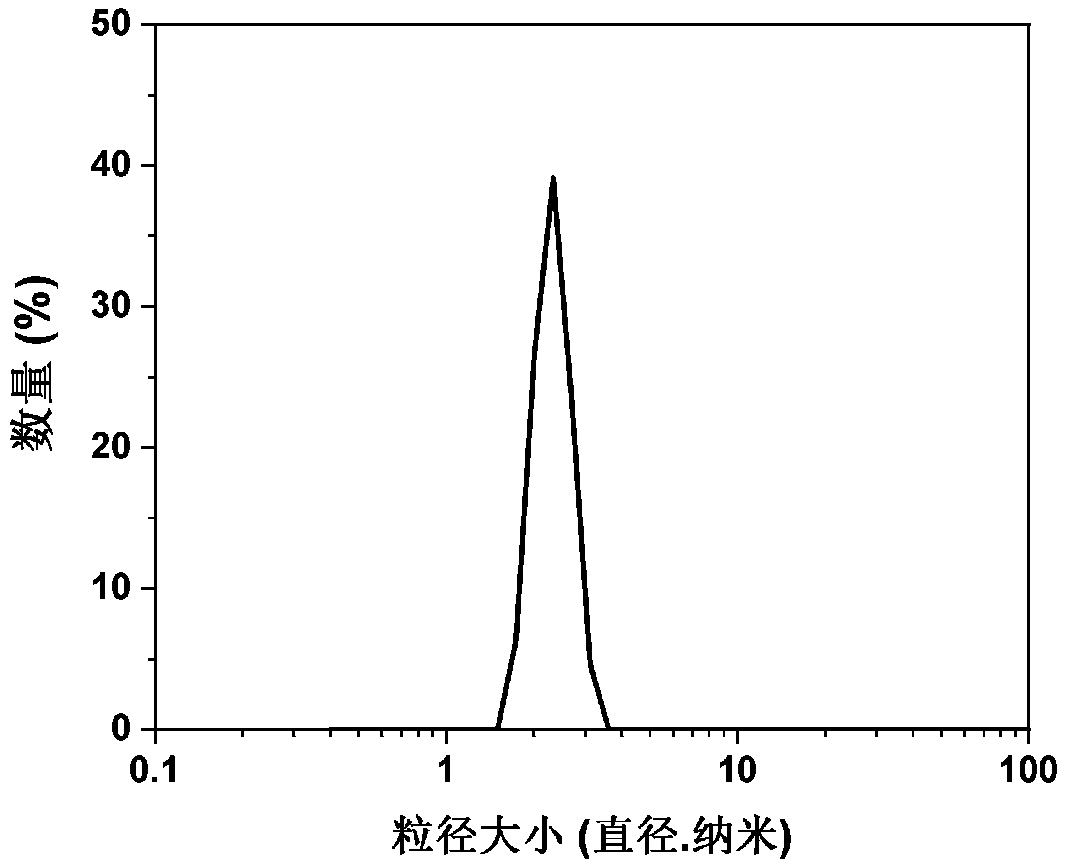

[0043] 4) The resulting solution was rotary evaporated under reduced pressure at 50°C for 30 minutes, and 0.5 g of OE-6636B glue was added. After testing, the particle size of nano titanium oxide uniformly dispersed in silica gel is 2.5 nanometers. The film was prepared by spin coating (4000 rpm, 15 seconds), and cured at 100 degrees for 1.5 hours. The compo...

Embodiment 3

[0045] 1) Weigh 0.277 g of zirconium n-propoxide, 0.101 g of acetic acid, and 0.468 g of organic silica gel A, and dissolve it in a bottle with 1.667 ml of solvent, and control the temperature of the solution at about 0°C;

[0046] 2) Add 0.030 grams of water to the solution prepared in 1), and control the temperature of the solution at about 0°C;

[0047] 3) Put the solution in an ice water bath and sonicate for 40 minutes to obtain a transparent zirconia nanoparticle dispersion.

[0048] 4) The resulting solution was rotary evaporated under reduced pressure at 50°C for 30 minutes, and 0.5 g of OE-6636B glue was added. After testing, the particle size of nano-zirconia uniformly dispersed in silica gel is 3.7 nanometers. The film is prepared by spin coating (4000 revolutions per minute, 1 second), and cured at 100 degrees for 1.5 hours. The composite packaging adhesive has a refractive index of 1.590 and a transmittance of 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com