Construction system for conveying mortar by long distance to fill sand bags

A long-distance, mortar technology, applied in water conservancy projects, sea area engineering, infrastructure engineering, etc., can solve problems such as lower work efficiency, high cost, and long distance of dredging and filling, so as to solve engineering problems, facilitate rapid circulation, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

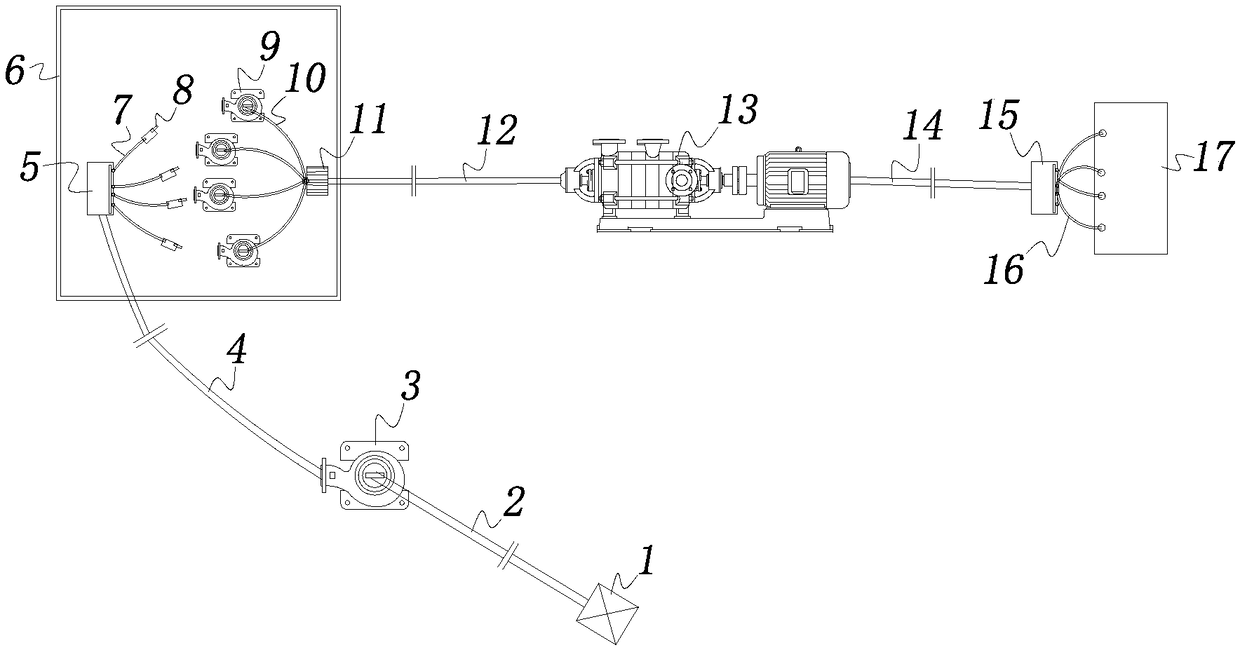

[0019] See figure 1 , The distance conveying mortar filling sand bag construction system of the present invention includes a sand storehouse 6 storing sand sources, and a high-pressure water distributor 5, a plurality of sediment pumps 9 and a confluencer 11 are arranged in the sand storehouse 6. The sand source in the sand storehouse 6 can be obtained from outsourcing, and can also be obtained from high-quality sand screened during engineering construction for sand preparation.

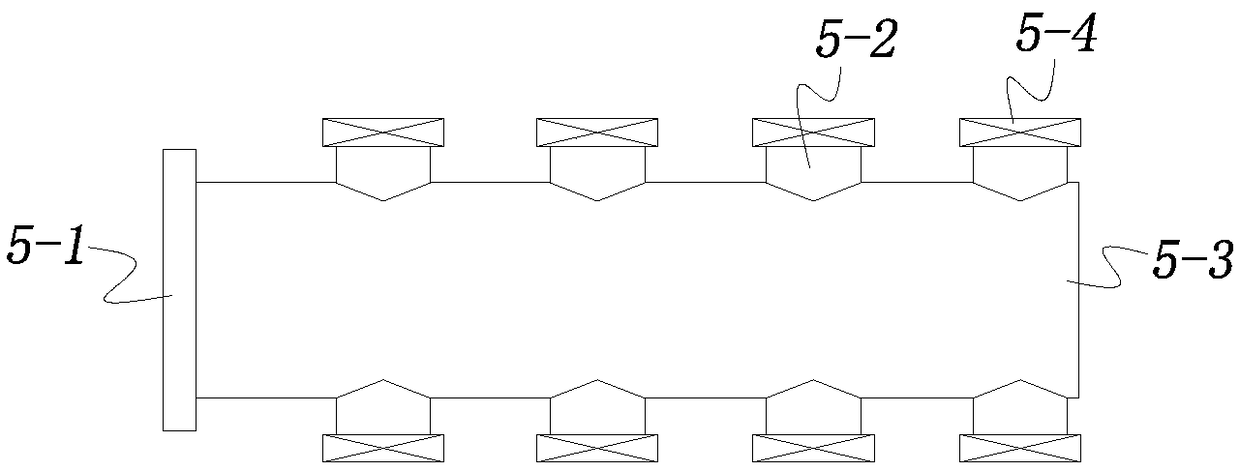

[0020] High pressure water distributor 5 comprises water tank 5-3, is provided with a plurality of water branch pipes 5-2 on the side wall of water tank 5-3, and the inlet of water tank 5-3 is connected to the outlet of a water pump 3 by water main pipe 4, and water pump The inlet of 3 is connected to water source by upper water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com