System and method for continuously purifying primary coolant loop of pressurized water reactor nuclear power unit

A technology for nuclear power units and pressurized water reactors, applied in nuclear power generation, radioactive purification, reactors, etc., can solve the problems of increasing the radiation exposure dose of maintenance personnel, low efficiency, filter blockage, etc., so as to reduce the radiation exposure dose and avoid Cross-contamination, the effect of preventing cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

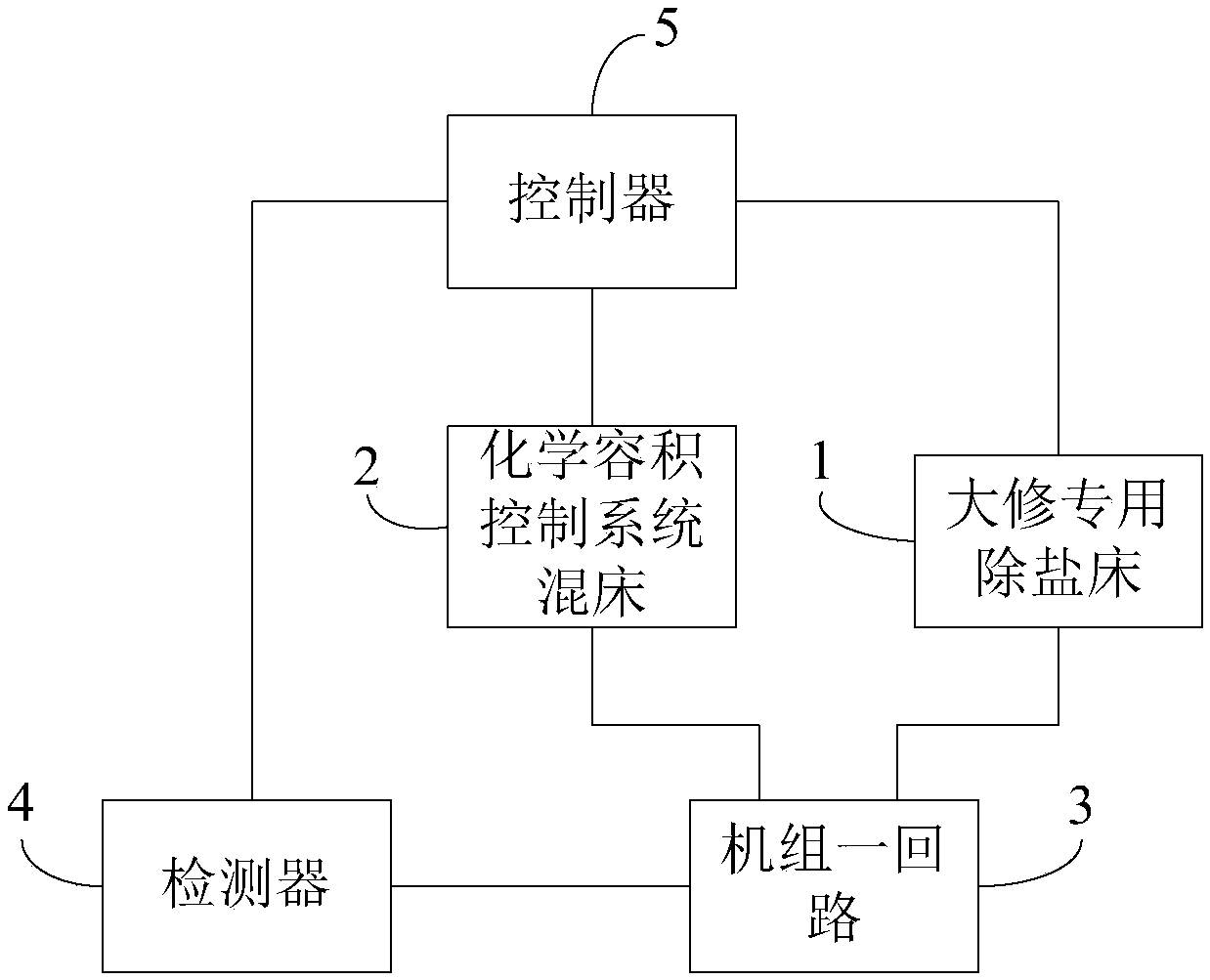

[0035] This embodiment provides a system for uninterrupted purification of the primary circuit of a pressurized water reactor nuclear power unit. This system is used for uninterrupted purification treatment of the primary circuit of a pressurized water reactor nuclear power unit. It has uninterrupted treatment, no cross-contamination, and reduces the radiation index The advantages.

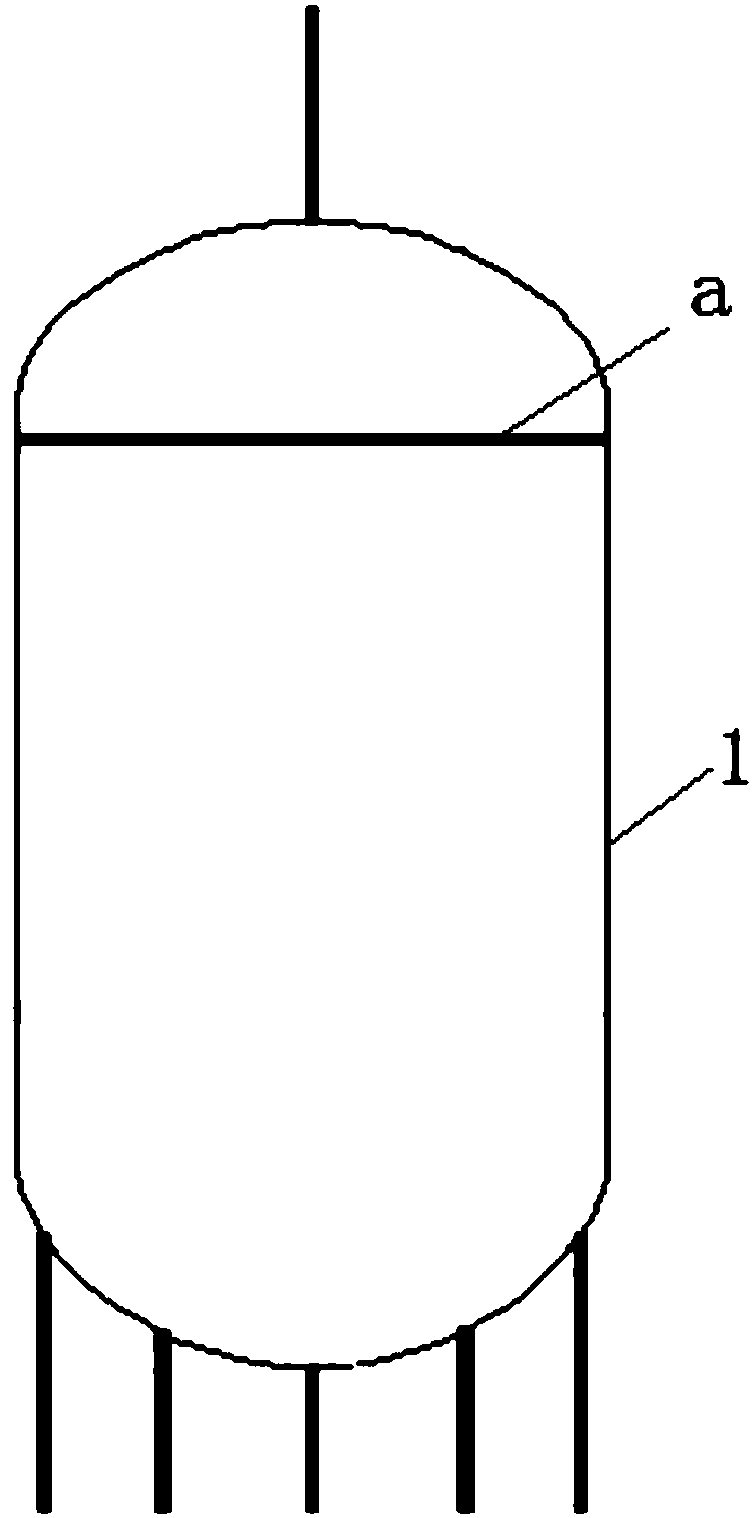

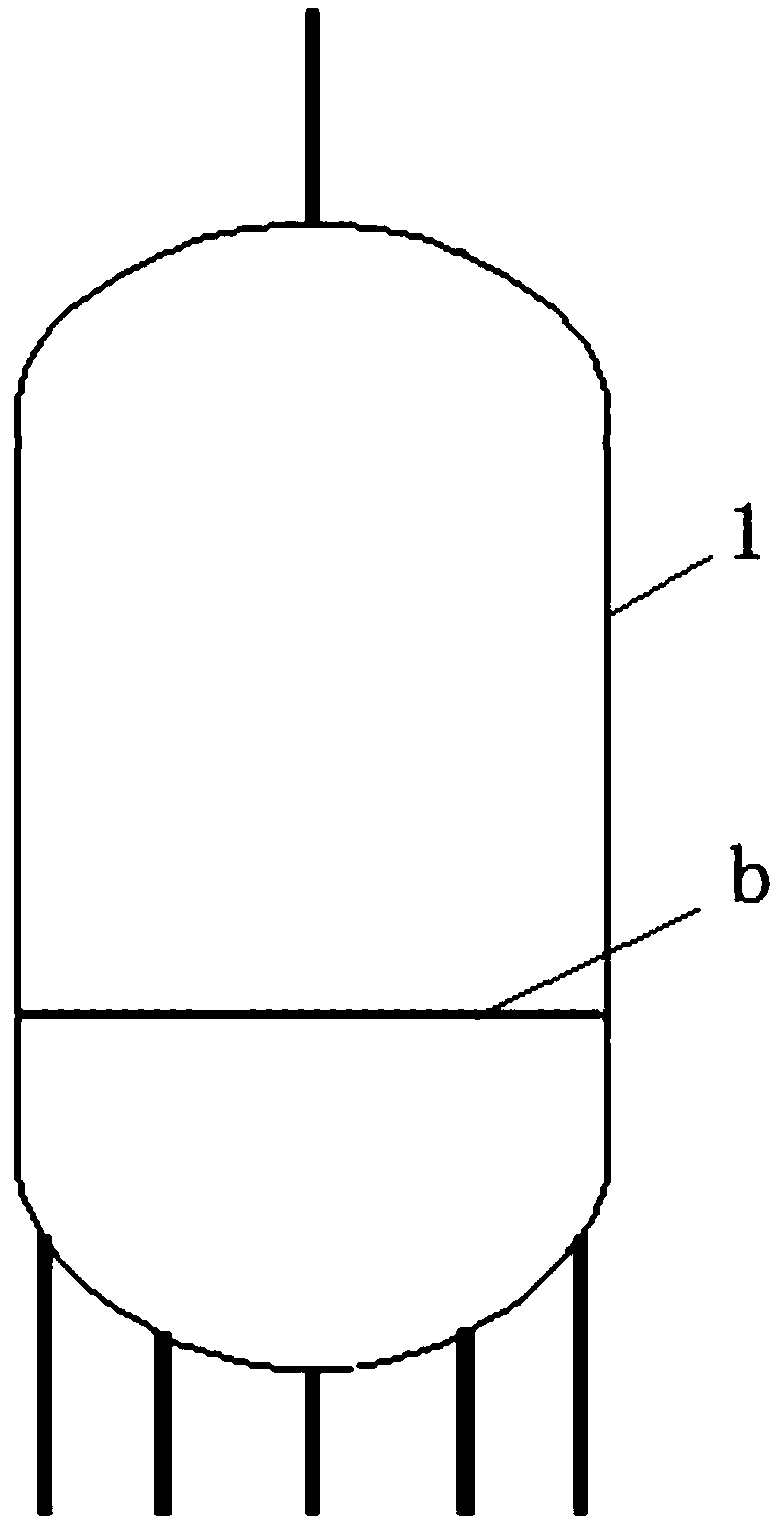

[0036] like figure 1 As shown, the system of this embodiment mainly includes the demineralization bed 1 dedicated for overhaul and the mixed bed 2 of the chemical volume control system, both of which are radioactive demineralization beds, for example, the special demineralization bed for overhaul Salt bed 1 is TEP006DE desalting bed, and mixed bed 2 of chemical volume control system is RCV mixed bed. Desalting bed 1 dedicated for overhaul and mixed bed 2 of chemical volume control system are cylindrical tanks filled with resin. The upper end of the cylindrical tank is provided with an inlet for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storey height | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com