A kind of zone oxidation ozone distributor and its layout and application

A distributor and ozone technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large ozone consumption, reduction of oxidation, ozone escape, etc., and achieve strong operability, rapid response, The effect of reducing the cost-benefit ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

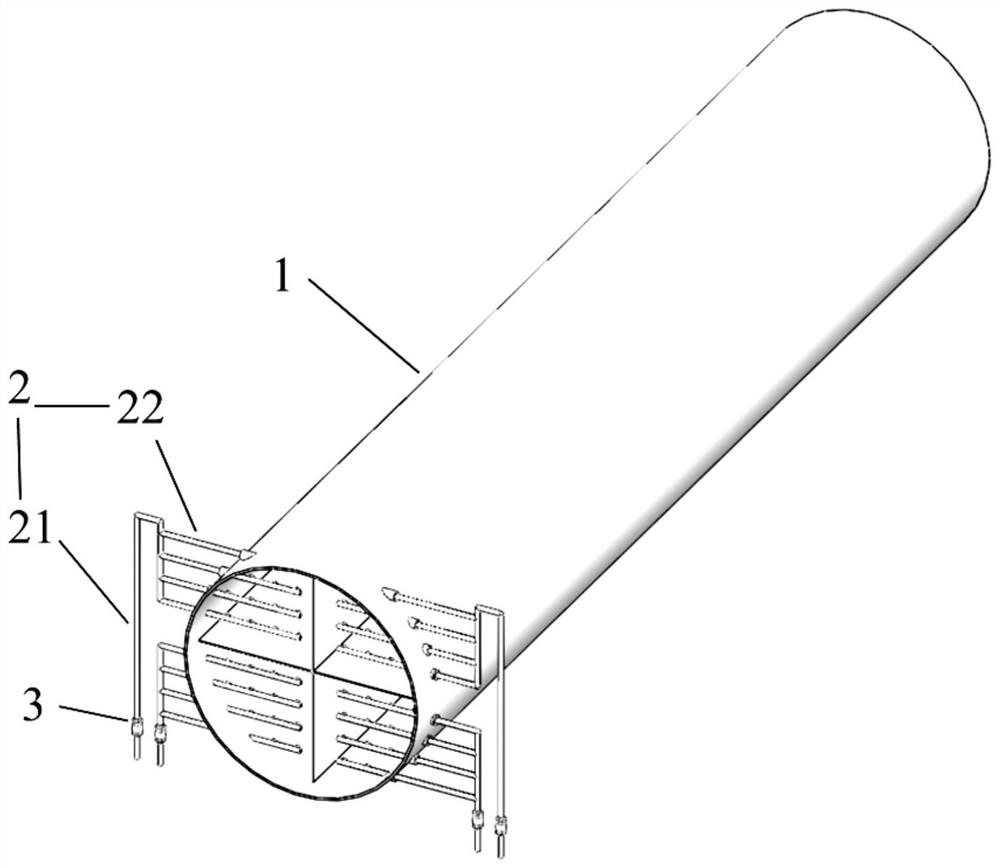

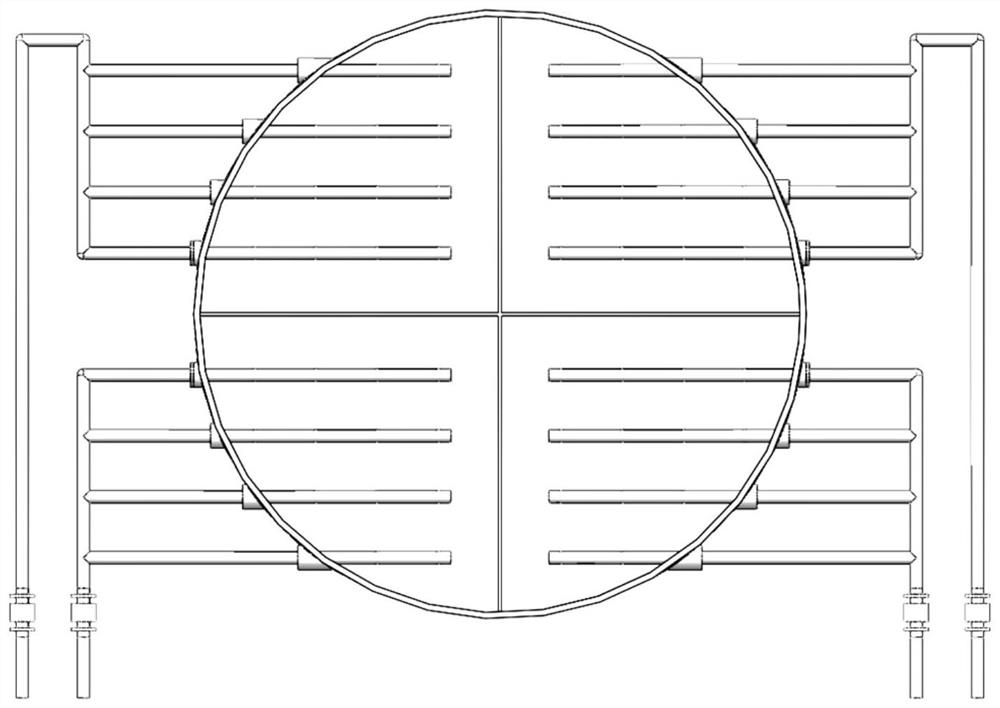

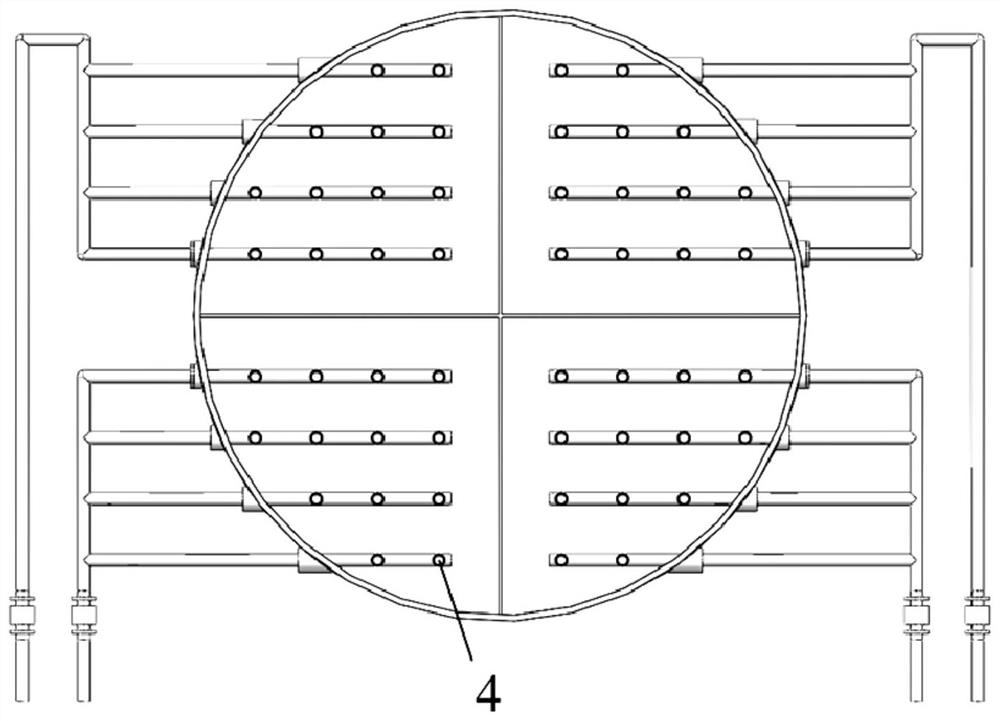

[0057] This embodiment provides an ozone distributor for zonal oxidation, the structural diagram of the ozone distributor is as follows figure 1 As shown, its front view, rear view and side view are as follows figure 2 , image 3 and Figure 4 As shown, it includes an ozone distributor main body 1 and an ozone delivery pipeline 2. The ozone distributor main body 1 is longitudinally divided into 4 distribution areas by a partition, each distribution area corresponds to a group of ozone delivery pipelines 2, and the ozone delivery pipeline 2 is set at one end of the main body 1 of the ozone distributor.

[0058] Wherein, one group of ozone delivery pipelines 2 includes a delivery main pipe 21 and a plurality of delivery branch pipes 22, the delivery main pipe 21 is provided with a flow regulating device 3, and the delivery branch pipe 22 is provided with a nozzle 4; The distances are equal, and the nozzles 4 are arranged on the conveying branch pipe 22 at equal intervals.

...

Embodiment 2

[0063] This embodiment provides an ozone distributor for zone oxidation. The ozone distributor refers to the ozone distributor in Example 1, the difference is that the reaction temperature is 90°C, the residence time of flue gas is 2s, and the flue gas in different distribution areas is mixed. The contact time is 1s.

Embodiment 3

[0065] This embodiment provides an ozone distributor for zone oxidation. The ozone distributor refers to the ozone distributor in Example 1. The difference is that the reaction temperature is 120°C, the residence time of the flue gas is 1s, and the flue gas in different distribution areas is mixed. The contact time is 0.75s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com