Extrusion device and method for oriented chopped carbon fiber reinforced thermoplastic composite

A technology of chopped carbon fiber and reinforced thermoplastic, which is applied in the field of composite material processing, can solve the problems of difficulty in uniform mixing, difficult to achieve directional arrangement of chopped carbon fiber filaments, easy clogging of molten thermoplastic composite materials, etc. The effect of direct contact and avoiding air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

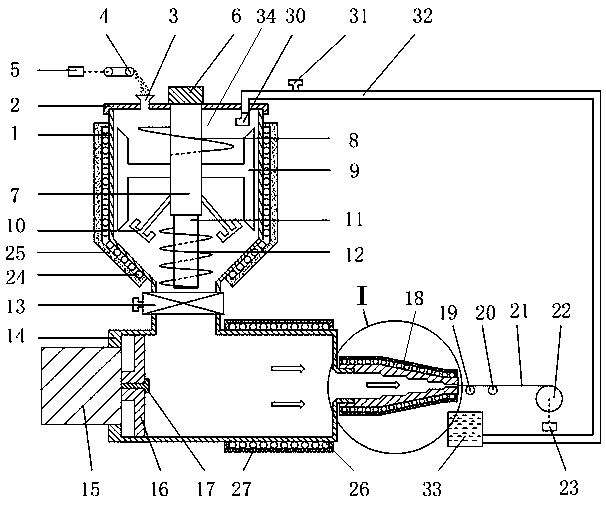

[0030] see figure 1 , The extruding device of directional chopped carbon fiber reinforced thermoplastic composite material according to the present invention includes: a mixing system, a telescopic hydraulic graded extruding system, an automatic coiling system, a heating system and an automatic cleaning system. The above-mentioned systems are all controlled by the main controller to achieve coordinated operation, and finally complete the preparation of chopped carbon fiber reinforced wire.

[0031] The mixing and stirring system includes: a melting chamber 1 , a sealing cover 2 of the melting chamber, a hopper 3 , a conveyor belt 4 , a conveying motor 5 , a stirring motor 6 , a multifunctional stirring device 34 and a gate valve 13 . The melting chamber 1 is vertically arranged up and down, and the sealing cover 2 of the melting chamber is installed at the installation place of the top opening, and the stirring motor 6 is vertically arranged above the sealing cover 2 of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com