A kind of preparation method of high bulk density silicon dioxide

A silicon dioxide and bulk density technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of large differences in product performance and insufficient control of product bulk density indicators, achieving low cost and easy product filling. The effect of installing and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

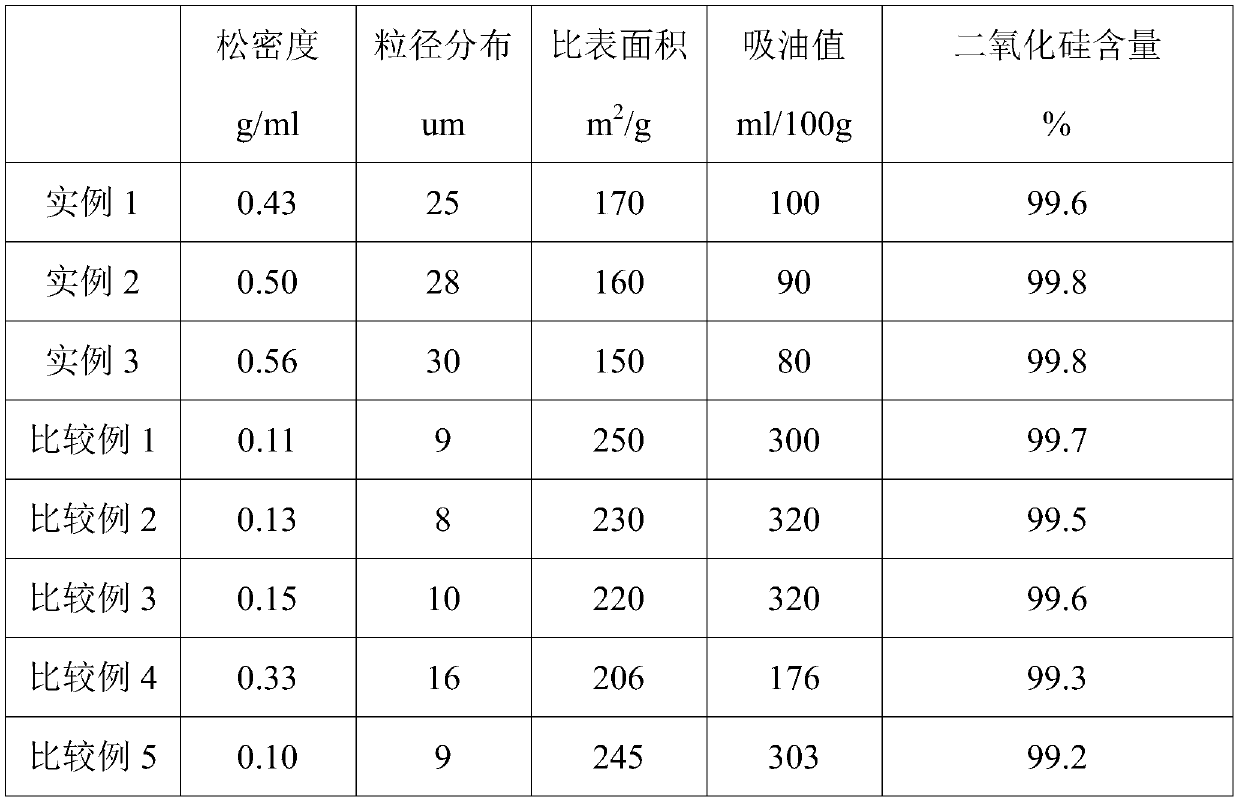

Examples

Embodiment 1

[0025] A preparation method of high bulk density silicon dioxide, comprising the following steps:

[0026] S1. Put sodium silicate with a modulus of 2.2 and purified water into the autoclave for dissolution, and prepare Na 2 O calculation, concentration is the sodium silicate aqueous solution A of 1.99mol / L;

[0027] S2. In the synthesis reaction kettle, mix 700L of sodium silicate aqueous solution A and 10000L of purified water in step S1 to obtain sodium silicate aqueous solution B with a concentration of 0.13mol / L, control the reaction temperature to 40°C, and add surfactant 10 Dialkyl sodium sulfate 4.28kg, open the stirring paddle, stir for 10 minutes, add dilute sulfuric acid in the reaction kettle through the rotameter, the flow rate of dilute sulfuric acid is 13L / min, the concentration of dilute sulfuric acid is 2mol / L, drop dilute sulfuric acid to The pH of the reaction system is 6.4-6.8, the time for adding dilute sulfuric acid is 60 minutes, and then standing and a...

Embodiment 2

[0031] A preparation method of high bulk density silicon dioxide, comprising the following steps:

[0032] S1. Put sodium silicate sodium silicate with a modulus of 2.4 and purified water into the autoclave for dissolution, and prepare Na 2 O calculation, concentration is the sodium silicate aqueous solution A of 2.15mol / L;

[0033] S2. In the synthesis reaction kettle, mix 700L of sodium silicate aqueous solution A and 10000L of purified water in step S1 to obtain sodium silicate aqueous solution B with a concentration of 0.14mol / L, control the reaction temperature at 38°C, and add surfactant 10 Dialkyl sodium sulfate 4.82kg, open the stirring paddle, stir for 10 minutes, add dilute sulfuric acid in the reaction kettle through the rotameter, the flow rate of dilute sulfuric acid is 13L / min, the concentration of dilute sulfuric acid is 2mol / L, drop dilute sulfuric acid to The pH of the reaction system is 6.4-6.8, the time for adding dilute sulfuric acid is 60 minutes, and the...

Embodiment 3

[0037] A preparation method of high bulk density silicon dioxide, comprising the following steps:

[0038] S1. Put sodium silicate with a modulus of 2.6 and purified water into the autoclave for dissolution, and prepare Na 2 O calculation, concentration is the sodium silicate aqueous solution A of 2.29mol / L;

[0039] S2. In the synthesis reaction kettle, mix 700L of sodium silicate aqueous solution A and 10000L of purified water in step S1 to obtain sodium silicate aqueous solution B with a concentration of 0.15mol / L, control the reaction temperature at 42°C, and add surfactant 10 Dialkyl sodium sulfate 5.35kg, open the stirring paddle, stir for 10 minutes, add dilute sulfuric acid in the reactor through the rotameter, the flow rate of dilute sulfuric acid is 13L / min, the concentration of dilute sulfuric acid is 2mol / L, drop dilute sulfuric acid to The pH of the reaction system is 6.4-6.8, the time for adding dilute sulfuric acid is 60 minutes, and then standing and aging for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com