Method for synchronously catalytically oxidizing non-degradable pollutants in secondary effluent and degrading remained sludge

A technology of excess sludge and secondary effluent, which is applied in the fields of advanced oxidation and bioelectrochemistry, and can solve the problems of high cost of excess sludge treatment and low utilization rate of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: A method of synchronously catalytically oxidizing refractory pollutants in secondary effluent water and degrading excess sludge in this embodiment is carried out according to the following steps:

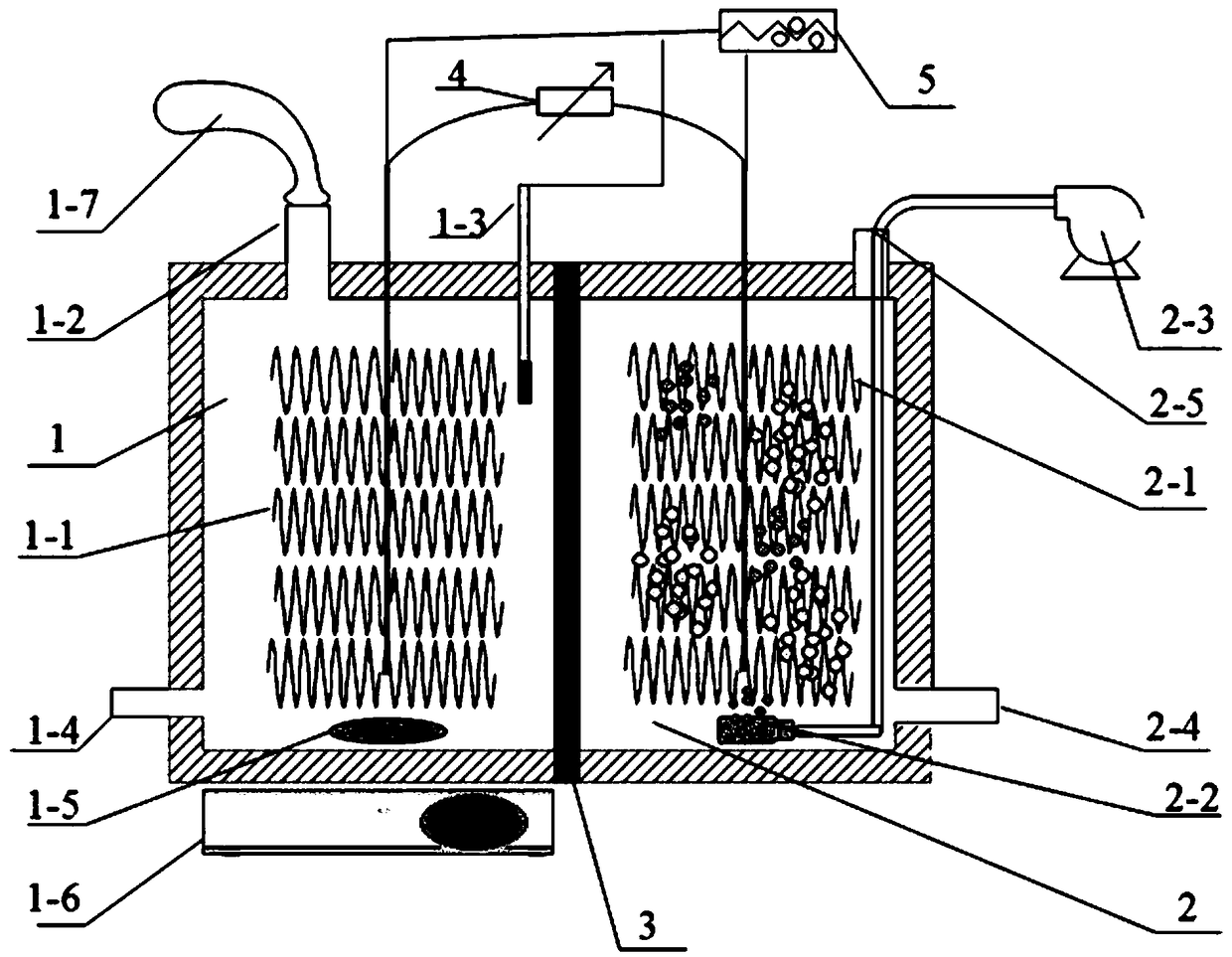

[0015] 1. Construct a bioelectrochemical coupling electro-Fenton synchronous degradation system: the reaction system consists of an anode chamber 1, a cathode chamber 2, a proton exchange membrane 3, an external resistance 4 and a multi-channel data collector 5; the proton exchange membrane 3 is set on the anode Between chamber 1 and cathode chamber 2; a carbon fiber brush 1-1 is placed in the middle of the anode chamber 1 as an anode, and the top is provided with a gas collection port 1-2 and a gas collection bag 1-7, and the calomel reference electrode 1-3 is partially inserted into the anode Indoor, the sampling port 1-4 is set under the anode chamber, the rotor 1-5 is placed at the bottom of the anode chamber, and the magnetic stirrer 1-6 is used for stirring...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the iron-containing composite electrode (2-1) described in step one is Fe&Fe 2 o 3 / carbon fiber or MnO 2 &Fe 2 o 3 / carbon fiber; others are the same as in Embodiment 1.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment two is: Fe&Fe 2 o 3 / The preparation method of carbon fiber is as follows: 1.8g FeCl 3 -6H 2 O was dissolved in 200ml of deionized water to obtain a ferric iron solution; 3.6g of NaBH 4 Dissolve in 80ml of deionized water to get NaBH 4 solution; brush the carbon fiber clean, after 20min ultrasonic in the ferric solution, NaBH 4 Add it into it, then wash it with deionized water, bake it in an oven at 105°C for 3 hours, take it out, and put it in a tube furnace protected by nitrogen, N 2 Intake air velocity is 50cm 3 / min, temperature 500°C, sintering for 3h, take it out and wash it with deionized water to get Fe&Fe 2 o 3 / carbon fiber. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com