A kind of preparation method of water-resistant pva biodegradable film

A technology of biodegradable film and water resistance, which is applied in the field of agricultural film, can solve the problems of PVA film industrial production development limitations, complex extrusion blow molding process, and complex PVA film preparation process, so as to promote the development of industrial production and improve Moisturizing effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

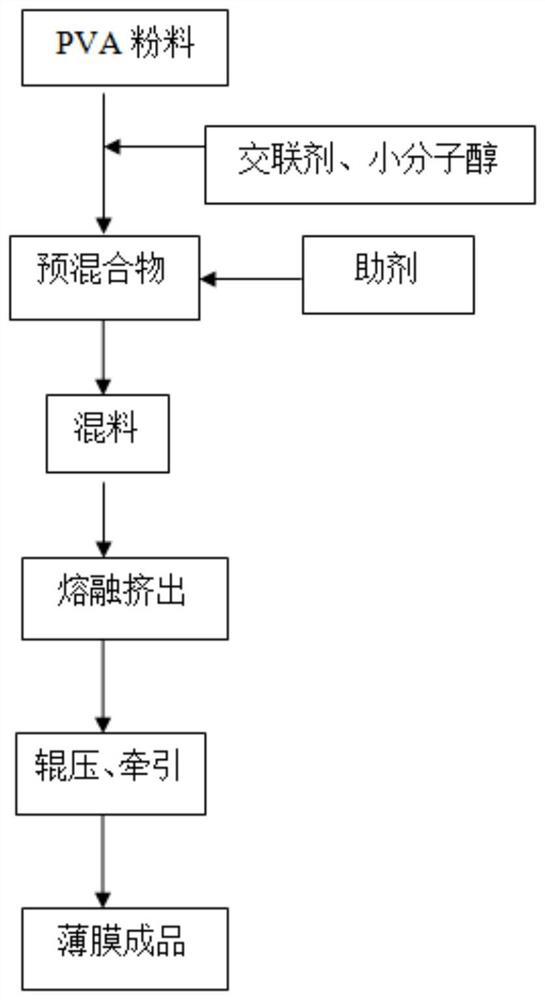

[0024] The invention provides a method for preparing a water-resistant PVA biodegradable film, the steps comprising:

[0025] a, prepare PVA aqueous solution with the raw material that comprises small molecule alcohol, PVA, water, crosslinking agent; b, use screw extruder to extrude PVA sheet.

[0026] In some preferred embodiments, the preparation method of a water-resistant PVA biodegradable film, in parts by weight, the steps include:

[0027] S1: Add 80-100 parts of PVA powder, 5-30 parts of small molecule alcohol, 0.1-10 parts of cross-linking agent and 20-300 parts of water into the high-speed mixer, and perform preliminary pre-treatment in the high-speed mixer. Mix to obtain PVA aqueous solution, the preparation temperature is 80°C to 95°C;

[0028] S2: Add 1 to 5 parts of lubricant, 0.1 to 10 parts of heat stabilizer, and 0.1 to 5 parts of sour taste remover to the PVA aqueous solution in sequence, and fully blend them in a high-speed mixer to obtain a mixture , and ...

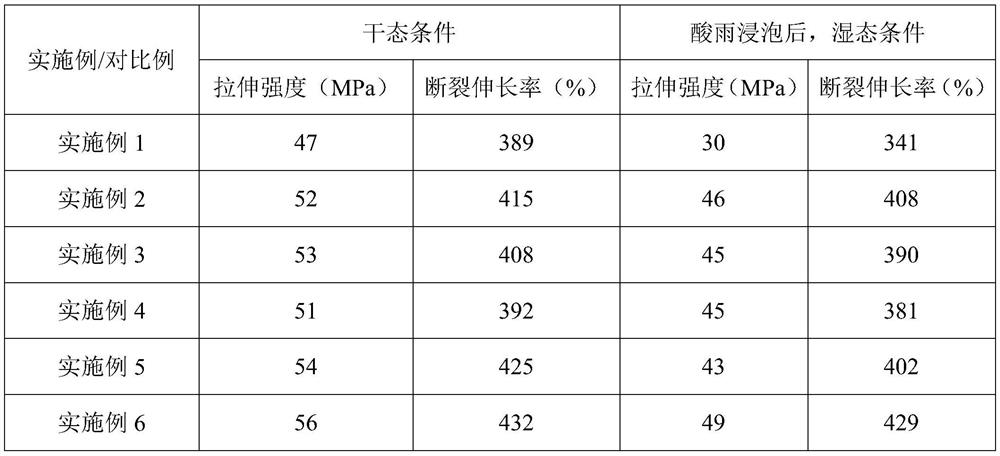

Embodiment 1

[0073] A preparation method of a water-resistant PVA biodegradable film, in parts by weight, comprising the steps of:

[0074] S1: Add 100 parts of polyvinyl alcohol powder, 5 parts of small molecule alcohol, 0.1 part of borax crosslinking agent and 100 parts of water into a high-speed mixer, and perform preliminary pre-mixing in the high-speed mixer to obtain a PVA aqueous solution , the preparation temperature is 80°C;

[0075] Wherein the degree of polymerization of the polyvinyl alcohol powder is 300, and the degree of alcoholysis is ≥ 98%;

[0076] Wherein the speed of the high-speed mixer described in S1 is 500 rpm;

[0077] Wherein the stirring time of the high-speed mixer described in S1 is 30 minutes;

[0078] Wherein the small molecule alcohol is a mixture of glycerol and pentaerythritol, wherein the weight ratio of glycerol and pentaerythritol is 1.5:1.

[0079] S2: In the PVA aqueous solution, add 3 parts of lubricant, 5 parts of heat stabilizer, and 2 parts of ...

Embodiment 2

[0091] A preparation method of a water-resistant PVA biodegradable film, in parts by weight, comprising the steps of:

[0092]S1: Add 100 parts of polyvinyl alcohol powder, 30 parts of small molecule alcohol, 10 parts of borax crosslinking agent and 100 parts of water into a high-speed mixer, and perform preliminary pre-mixing in the high-speed mixer to obtain a PVA aqueous solution , the preparation temperature is 95°C;

[0093] Wherein the degree of polymerization of the polyvinyl alcohol powder is 2400, and the degree of alcoholysis is ≥ 98%;

[0094] Wherein the speed of the high-speed mixer described in S1 is 800 rpm;

[0095] Wherein the stirring time of the high-speed mixer described in S1 is 90 minutes;

[0096] Wherein the small molecule alcohol is a mixture of glycerol and pentaerythritol, wherein the weight ratio of glycerol and pentaerythritol is 1.5:1.

[0097] S2: In the PVA aqueous solution, add 3 parts of lubricant, 5 parts of heat stabilizer, and 2 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com