Preparation method of ammonium polyphosphate cladded microsphere flame retardant

An ammonium polyphosphate and flame retardant technology, which is applied in the field of inorganic flame retardant preparation, can solve the problems of interface problems, deterioration of polymer matrix mechanical properties, research on single-component IFR system, and large addition of single-component flame retardants. , to achieve the effect of suppressing smoke production, reducing fire risk, and improving the problem of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add 80ml deionized water and 4g APP into the three-necked flask, heat to 75°C, and stir thoroughly for 1 hour to obtain APP suspension.

[0045] Add 1g of CMSs, 0.5ml of glacial acetic acid, 1ml of KH-550 and 50ml of absolute ethanol into a beaker, and perform silanization reaction at 30°C for 30min.

[0046] Pour the above-prepared silanized modified CMSs reaction dispersion into the APP suspension, reflux at 80° C. for 2 h, and pour off the supernatant to obtain a crude CMSs-APP product.

[0047] The CMSs-APP crude product was dried at 80°C for 12h, ground, washed several times with absolute ethanol to remove unreacted KH-550 and other impurities, and then dried at 80°C for 12h to prepare the CMSs-APP flame retardant.

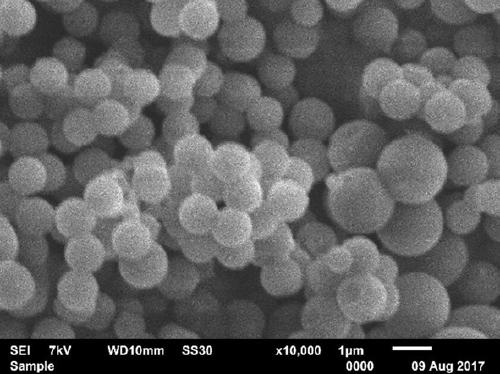

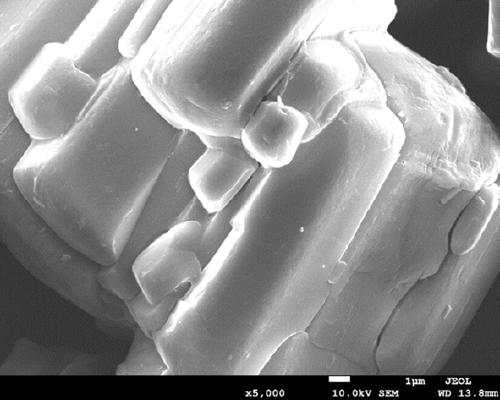

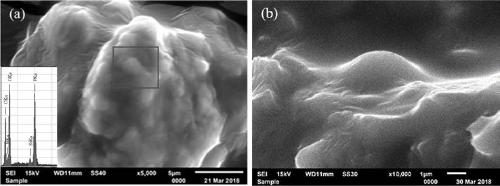

[0048] The above results were verified by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). figure 1 The morphology diagram of the raw material CMSs is given, which shows that the CMSs are spherically distributed, with smoot...

Embodiment 2

[0058] Add 80ml of deionized water and 2g of APP into the three-necked flask, heat to 80°C, and stir thoroughly for 1 hour to obtain APP suspension.

[0059] Add 1g of CMSs, 1ml of glacial acetic acid, 1.5ml of KH-550 and 50ml of absolute ethanol into a beaker, and perform silanization reaction at 40°C for 40min.

[0060] Pour the above-prepared silanized modified CMSs reaction dispersion into the APP suspension, reflux at 85° C. for 3 h, and pour off the supernatant to obtain a crude CMSs-APP product.

[0061] The CMSs-APP crude product was dried at 90°C for 18h, ground, washed several times with absolute ethanol to remove unreacted KH-550 and other impurities, and then dried at 90°C for 12h to prepare the CMSs-APP flame retardant.

Embodiment 3

[0066] Add 100ml of deionized water and 1g of APP into the three-necked flask, heat to 85°C, and stir thoroughly for 1 hour to obtain APP suspension.

[0067] Add 1g of CMSs, 1.5ml of glacial acetic acid, 2ml of KH-550 and 50ml of absolute ethanol into a beaker, and perform silanization reaction at 50°C for 50min.

[0068] Pour the above-prepared silanized modified CMSs reaction dispersion into the APP suspension, reflux at 90°C for 4 hours, and pour off the supernatant to obtain a crude CMSs-APP product.

[0069] The CMSs-APP crude product was dried at 100°C for 24h, ground, washed several times with absolute ethanol to remove unreacted KH-550 and other impurities, and then dried at 100°C for 24h to prepare the CMSs-APP flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com