Production technology of auto-suspension proppant

A production process and proppant technology, which is applied in the production process field of self-suspension proppant, can solve problems such as increased cost and environmental pollution, and achieve the effects of low equipment and energy consumption, short process time, and low coating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

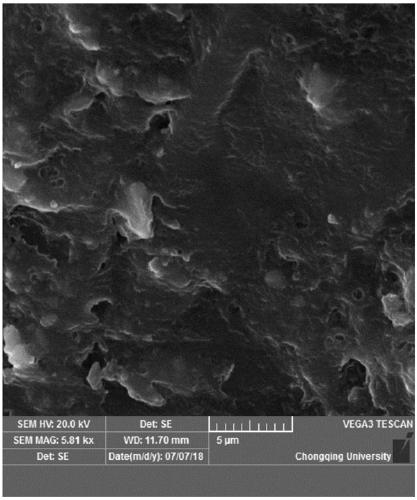

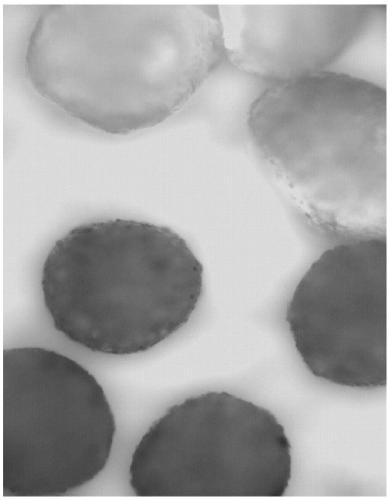

Image

Examples

Embodiment 1

[0044] Take the apparent density as 1.1g / cm 3 100 parts of ceramsite and quartz sand with a particle size of 20 / 40, heated to 180°C, pour the heated ceramsite and quartz sand into a bowl-shaped mixing casserole and stir, and add 1 part of epoxy resin after the temperature reaches 170-180°C Stir the resin and 0.25 parts of curing agent T31, add 5 parts of propylene glycol polymer and 0.01 part of dibutyltin dilaurate after the temperature reaches 110-130 ° C, add 0.005 parts of diethylene triamine and Stir the mixture of ethylenediamine, add 3.5 parts of isocyanate and stir when the temperature reaches 80-110°C, and take out the pot when the temperature reaches 40-70°C.

Embodiment 2

[0046] Take the apparent density as 1.6g / cm 3 , The particle size is 30 / 50 ceramsite and quartz sand, a total of 100 parts, heat the mixture of ceramsite and quartz sand to 200 ° C, pour it into a bowl-shaped mixing casserole, and add 5 parts of phenolic formaldehyde when the temperature reaches 180-190 ° C Stir the resin, when the temperature reaches 160-170°C, add 1.5 parts of hexamethylenetetramine and stir, when the temperature reaches 100-120°C, add 4 parts of ethylene glycol polymer and stir, when the temperature reaches 80-100°C Add 0.04 parts of dibutyltin dilaurate and stir, add 2.3 parts of isocyanate when the temperature reaches 80-100°C and stir, and take out the pot when the temperature reaches 40-70°C.

Embodiment 3

[0048] Take the apparent density as 2.2g / cm 3 100 parts of ceramsite and quartz sand with a particle size of 40 / 70. Heat the mixture of ceramsite and quartz sand to 230°C and pour it into a bowl-shaped mixing casserole. After the temperature reaches 190-230°C, add 6 parts of epoxy Stir the ester resin, add 2.7 parts of curing agent T31 when the temperature reaches 160-170°C and stir, add 3 parts of ethylene glycol polymer and stir when the temperature reaches 160-170°C, add Stir 0.03 parts of dibutyltin dilaurate, add 0.6 parts of ethylamine and stir when the temperature reaches 100-110°C, add 2 parts of diphenyl diisocyanate and stir when the temperature reaches 80-100°C, and stir when the temperature reaches 40-70 Take out the pot between ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com