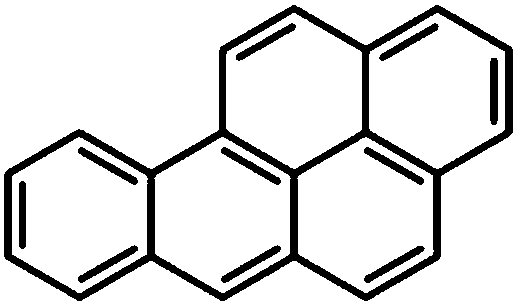

Process for preparing low content benzo (alpha) pyrene peanut oil

A production process, low-content technology, applied in the direction of fat oil/fat refining, fat production, fat oil/fat production, etc., can solve the problems of poor removal effect, loss of nutrients, and insignificant results, and simplify the post-processing process. , Good removal effect, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Impurity cleaning: The raw peanut kernels are poured into the raw material pit, and then enter the aroma pressing workshop through scraper conveyors and bucket elevators. After the TCXT20 magnetic separator absorbs iron filings or iron lumps, the TQLZ150*200 vibrating screen screens and removes impurities, the TQSF175 specific gravity stone remover removes large and small stones, and the supporting bag filter and cyclone Shacron pipe network system dedust. Entering the storage box, the temporarily stored raw materials are transported into the weighing scale through the screw conveyor and the bucket elevator, and weighed and measured.

[0027] (2) Roasting seeds: The cleaned materials enter the RLXCZ type natural gas continuous seed frying furnace, and roast at a roasting temperature of 162°C for 22 minutes, and the roasting is completed after the whole peanut kernels turn light yellow.

[0028] (3) Oil pressing: The roasted materials are quickly transferred to the 1...

Embodiment 2-6

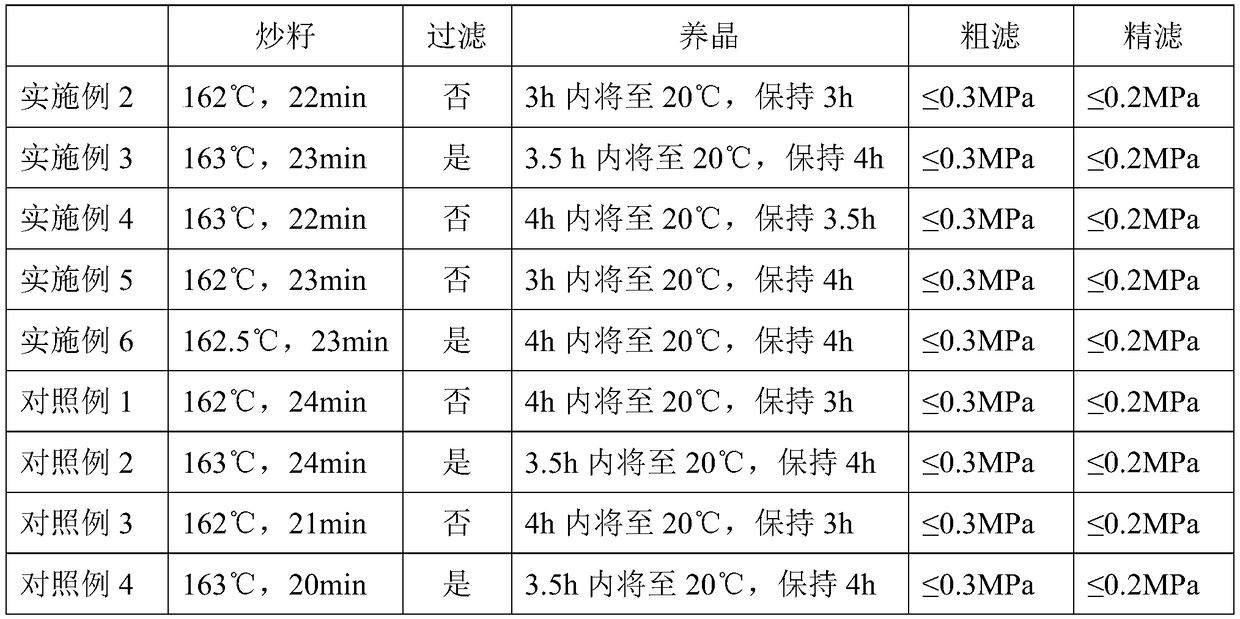

[0034] Embodiment 2-6, comparative example 1-16

[0035]The technical parameters of the steps of frying seeds, filtering, growing crystals, rough filtering, and fine filtering of Examples 2-6 and Comparative Examples 1-16 are shown in the table below, and other steps are the same as in Example 1.

[0036]

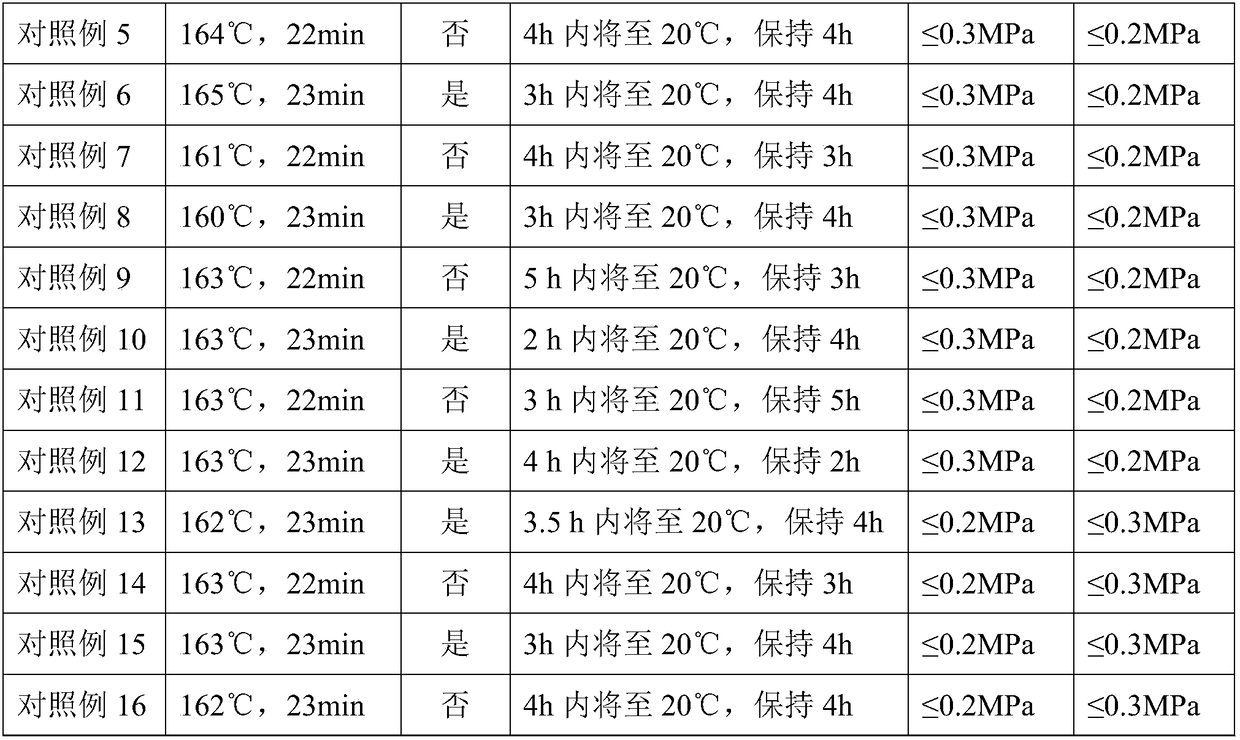

[0037]

experiment example

[0039] Utilize the routine detection method in this field (GB / T 5009.27-2003 benzo (alpha) pyrene content determination method, GB / T 26635-2001 vitamin E content determination method, GB / T 25223-2010 sterol content determination method, LS / T6120-2017 content determination method of squalene), benzo (alpha) pyrene, vitamin E, sterol, squalene The content of alkenes is detected, and the results are as follows:

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com