Basement bottom plate structure high in floating and cracking resistance and design method thereof

A technology of basement floor and design method, which is applied in the directions of underwater structures, infrastructure engineering, building construction, etc., can solve the problems of reducing the service life of the floor structure, difficult to permanently repair, increasing investment, etc., so as to reduce the tensile stress. and shear stress, thickness and reinforcement ratio reduction, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the directional terms and order terms mentioned in the following embodiments, such as "upper", "lower", "front", "back", "left", "right", etc., are only referring to the accompanying drawings. Direction, therefore, the use of directional terms is for illustration and not for limitation of the invention.

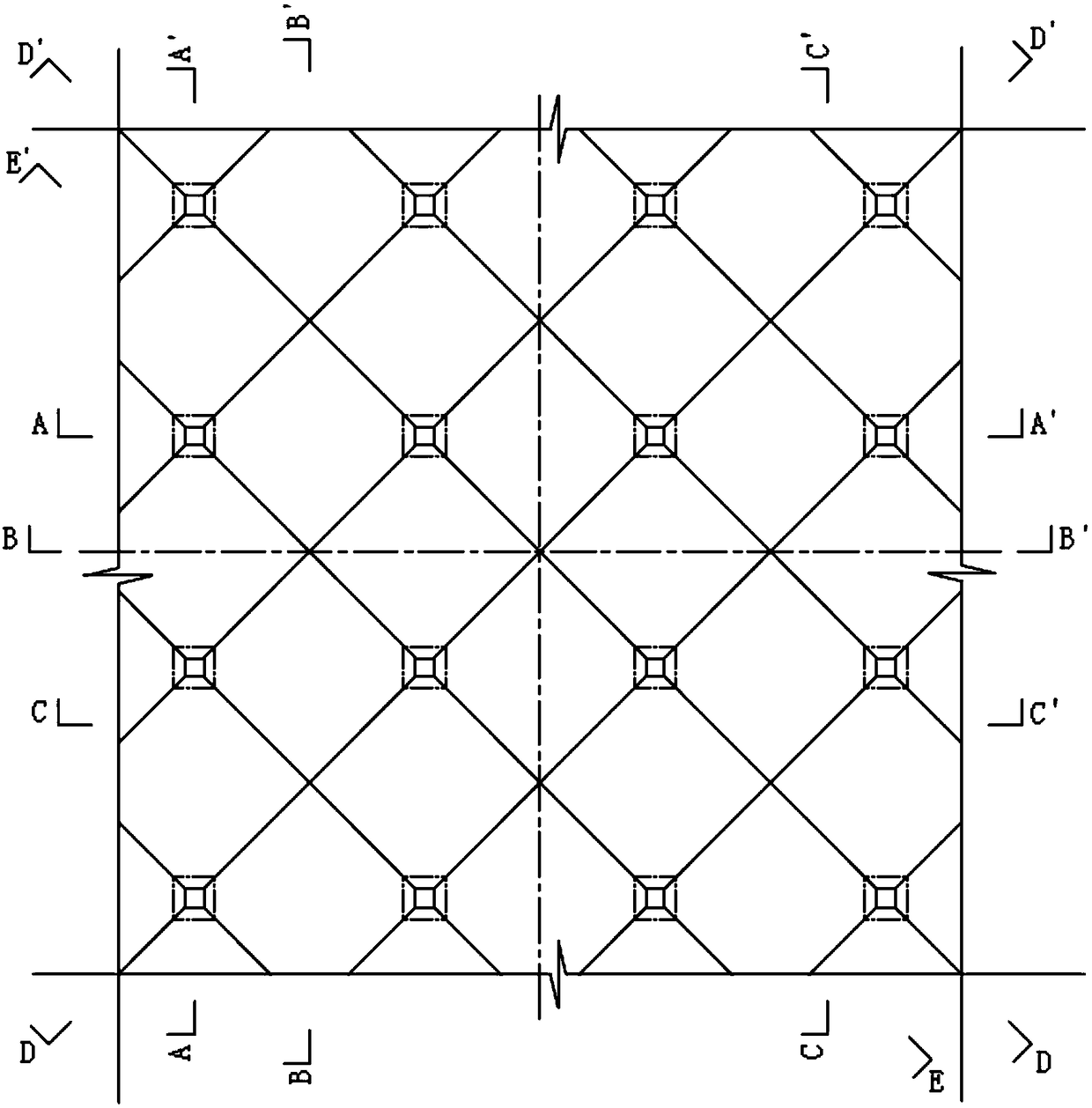

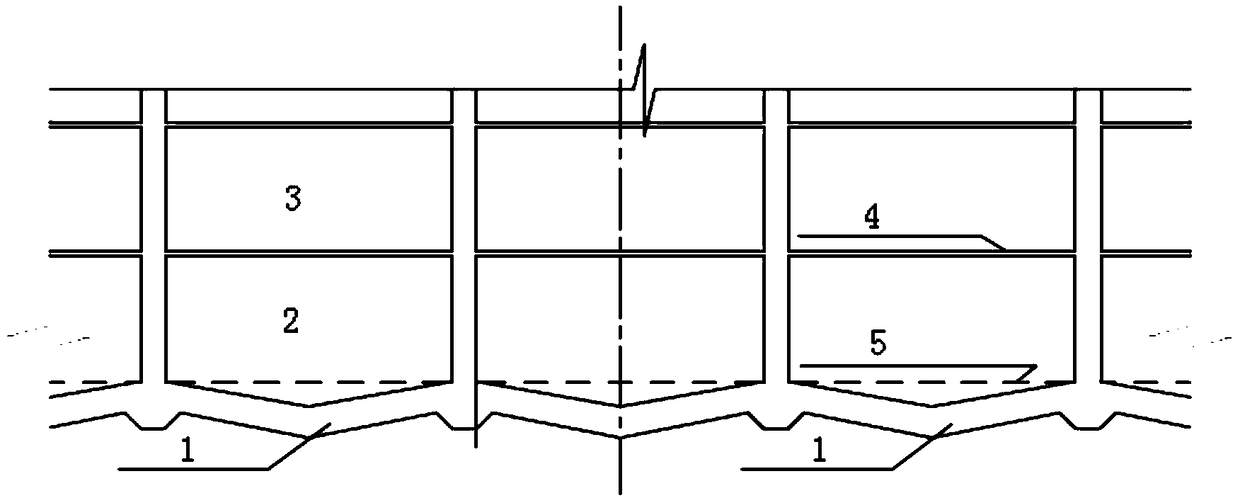

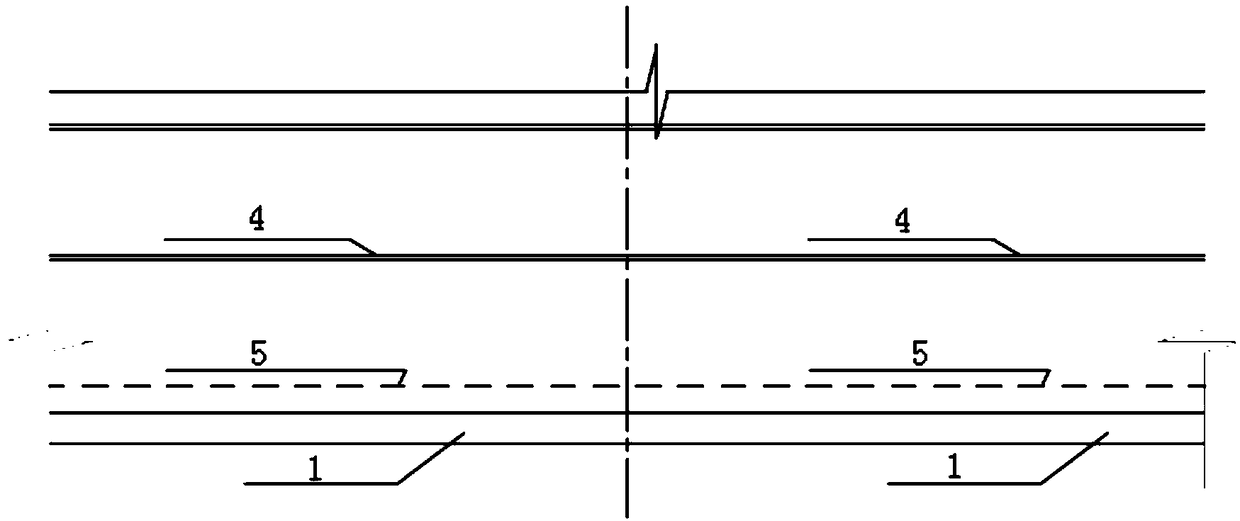

[0041] Such as Figure 1-11 As shown, in this embodiment, taking two-way 10m and other column center distances as an example, the basement floor structure with high anti-floating and crack resistance provided by the present invention is shown. The part is the part between four adjacent columns that can form a square on the basement floor. It is worth noting that in other cases (such as irregular column center distance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com