Wind tunnel test method for coaxial double-rotor hub model of helicopter

A coaxial twin-rotor, wind tunnel test technology, applied in the field of propeller hub wind tunnel test, can solve the problems of low speed, complex shape, small test Reynolds number, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

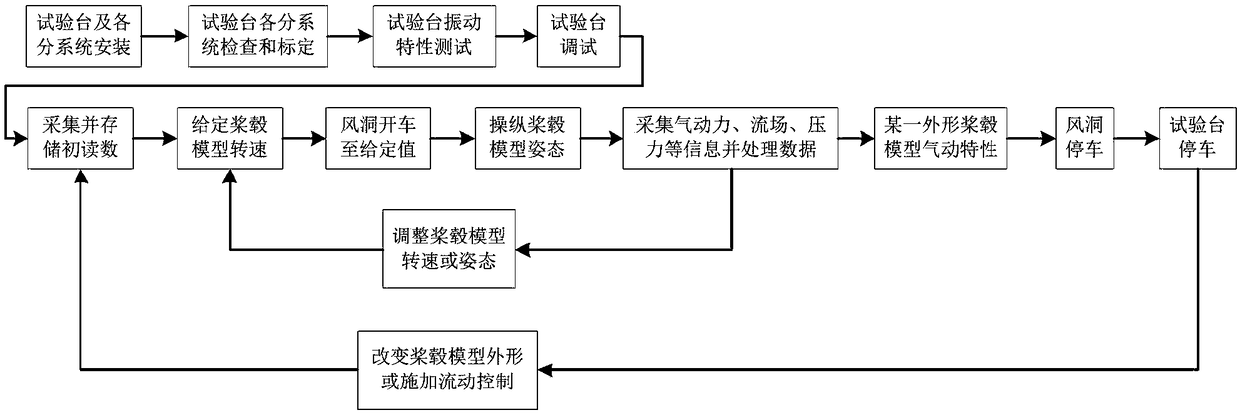

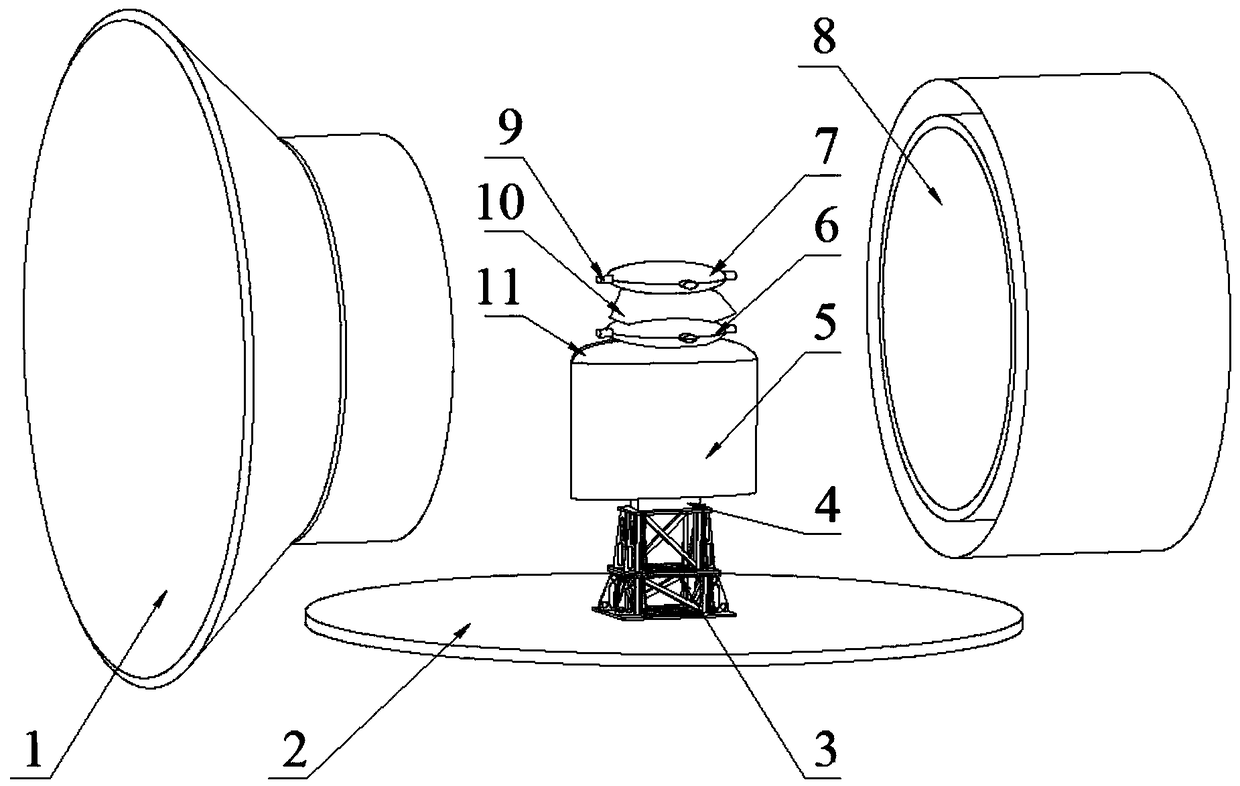

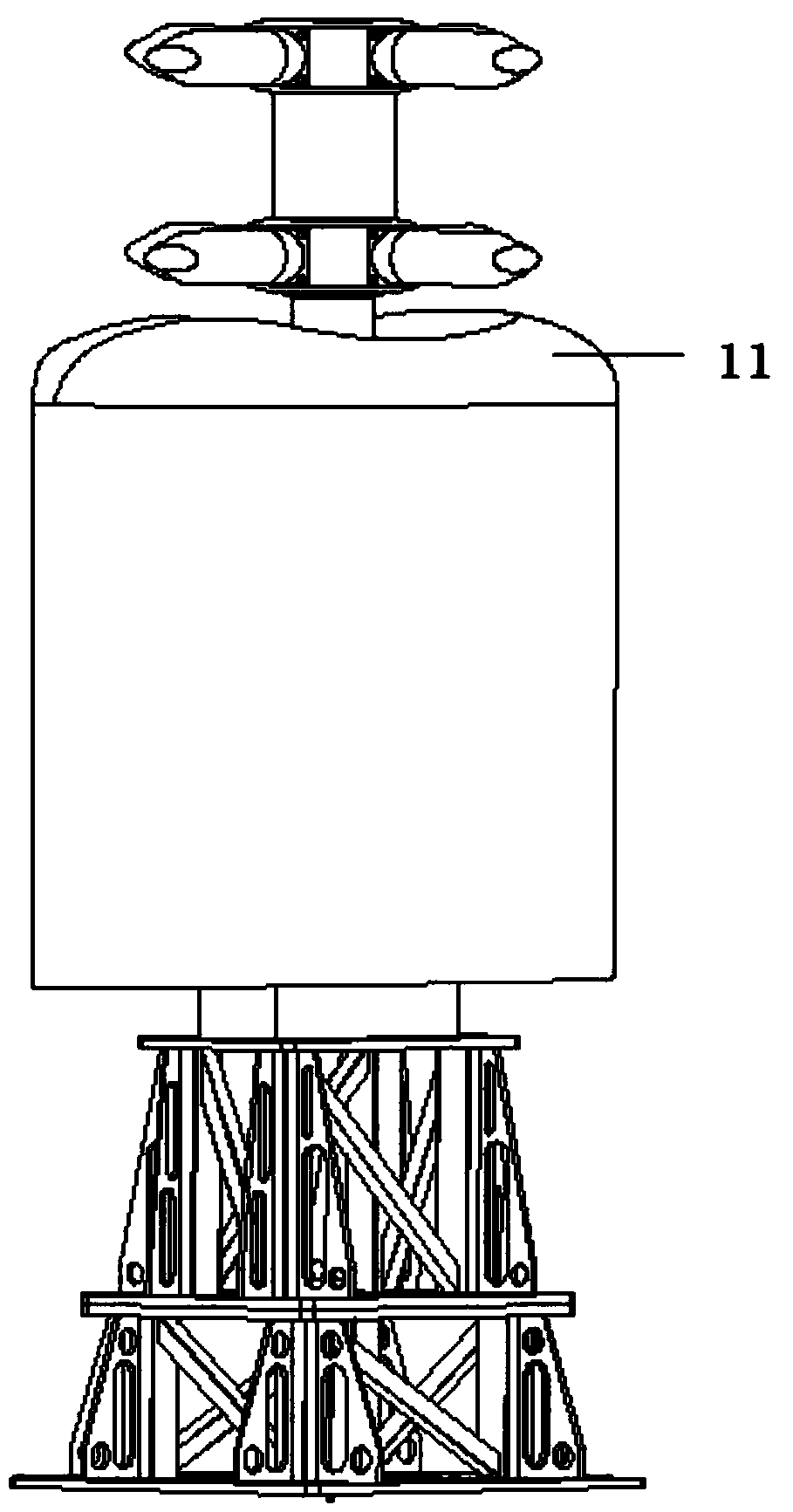

[0061] The invention discloses a first embodiment of a wind tunnel test method for a helicopter coaxial dual-rotor hub model. like figure 2 As shown, firstly, the coaxial dual-rotor hub model test bench is installed in the wind tunnel test section, and connected to the wind tunnel test system; the function and stability of each subsystem are checked, and the balance system, PIV measurement system, surface pressure measurement The system is checked and the check / calibration result is given; the installation is as follows image 3 For the hub model shown (upper and lower hub + fairing without intermediate shaft + tower), the vibration characteristics of the test bench are measured by the vibration monitoring system, and the ground resonance analysis and the vibration removal work of the test bench are carried out to ensure that the hub model test Resonance does not occur at any time; check the coordination, function and integrity of the structure of the propeller hub model to ...

Embodiment 2

[0066] Compared with Embodiment 1, except that the supporting frame 3 of the test bench is different, other structures and methods are the same. The supporting platform 3 of the test bench is replaced by a six-degree-of-freedom platform, which can not only change the sideslip angle of the test model, but also realize the change of the pitch angle and roll angle of the test model, enriching the test content.

[0067] At the same time, this method can not only carry out the wind tunnel test of the coaxial double hub model, but also carry out the wind tunnel test of the single hub model after removing one hub, and can also carry out the independent hub model, the single intermediate shaft fairing and the A wind tunnel test study on the shape optimization of a single tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com