Design method of electron gun of traveling wave tube based on multi-objective optimization algorithm

A multi-objective optimization and optimal design technology, applied in the field of microwave electric vacuum, can solve problems such as difficulty in taking into account multiple optimization objectives, low efficiency, and long time-consuming scanning methods, so as to avoid difficulty in taking into account multiple relatively independent optimization objectives and time-consuming The effect of low complexity and uniform distribution of solution sets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

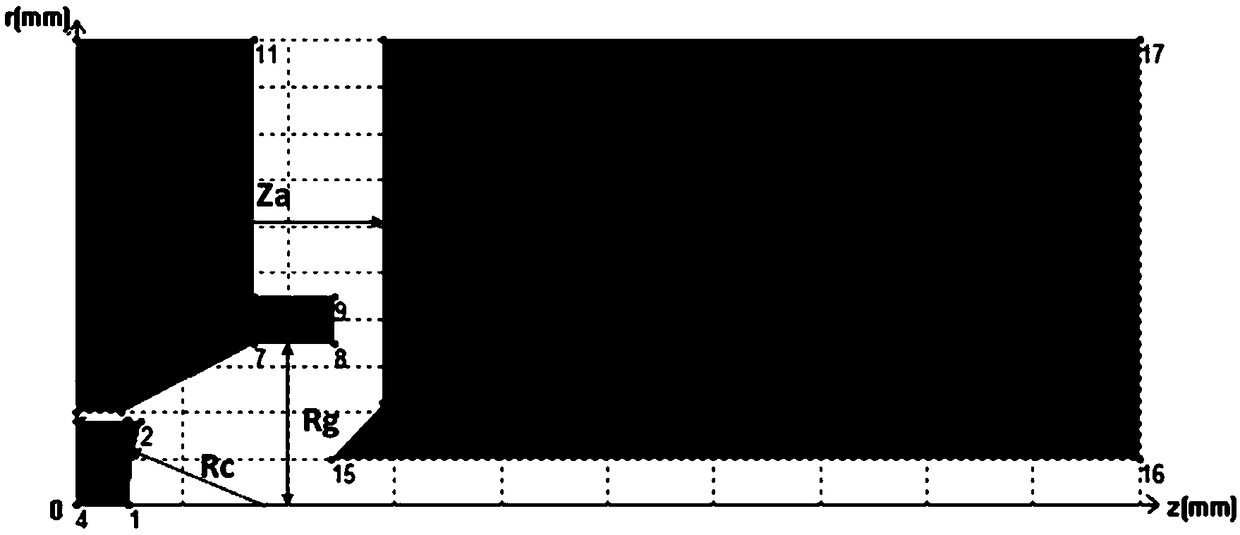

[0031] Utilizing computer CAD technology to simulate the design of the TWT electron gun is a common method in the design of the TWT electron optical system. The present invention optimizes the design of the TWT electron gun by means of the electron optical system simulation software EOS.

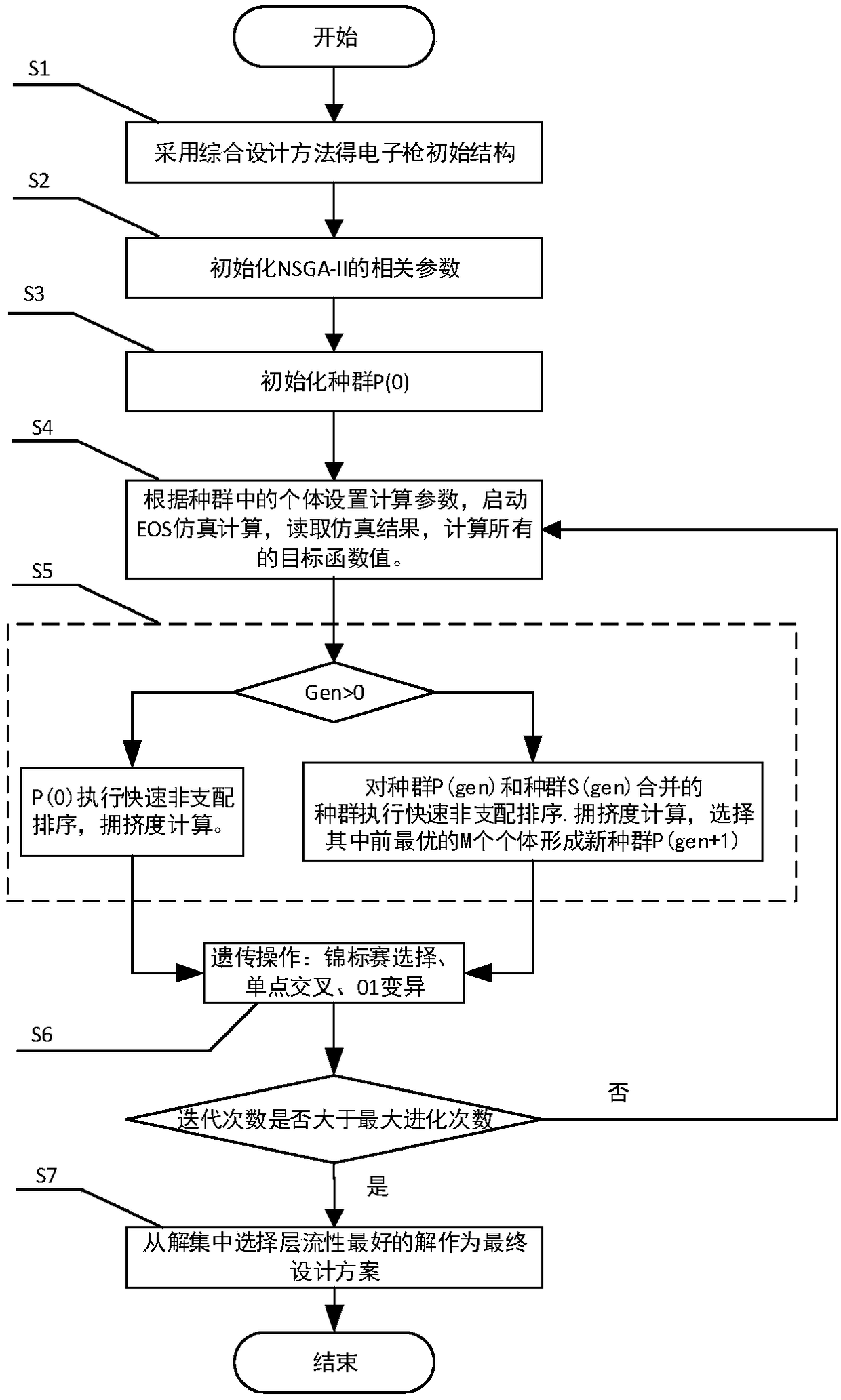

[0032] Specific steps are as follows:

[0033] S1. According to the design goals of cathode emission current, injection waist radius, cathode voltage, and electron injection range, etc., the initial structure of the electron gun is obtained by using the rapid comprehensive design method:

[0034] Set the parameters of the TWT electron optical system: set the model to 2D, the global grid size to 2.0mm, the grid self-adaptation to No, the number of secondary electron calculations to 4, and the rest of the parameters to default.

[0035] S2, set the relevant p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com