Back-illuminated image sensor and forming method thereof

An image sensor and back-illuminated technology, which is applied in the field of image sensors, can solve the problems of complex manufacturing process and improvement, and achieve the effects of simple process, preventing or weakening crosstalk, and easy formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

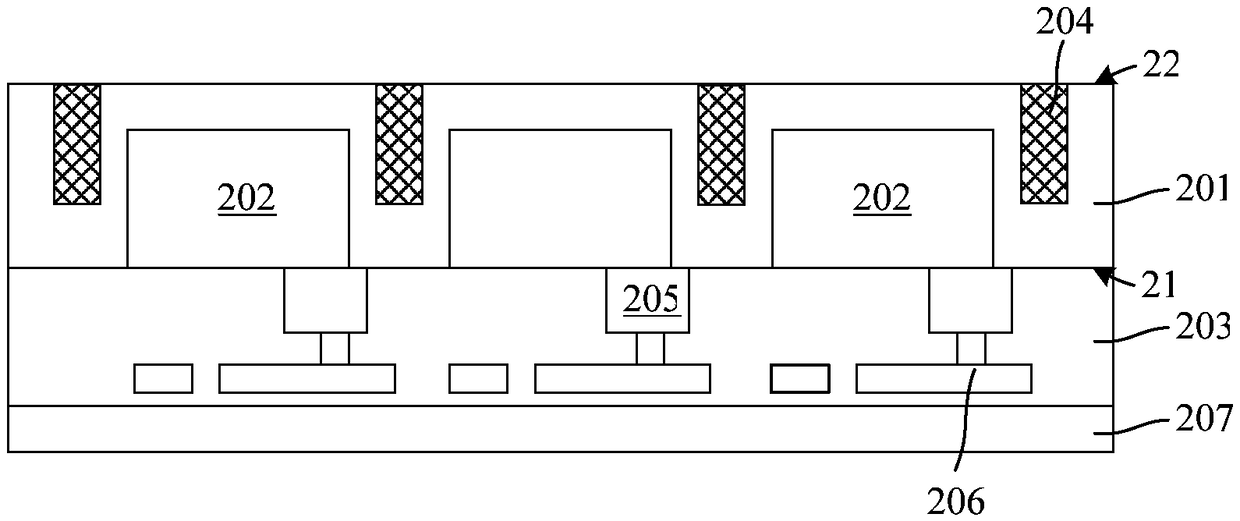

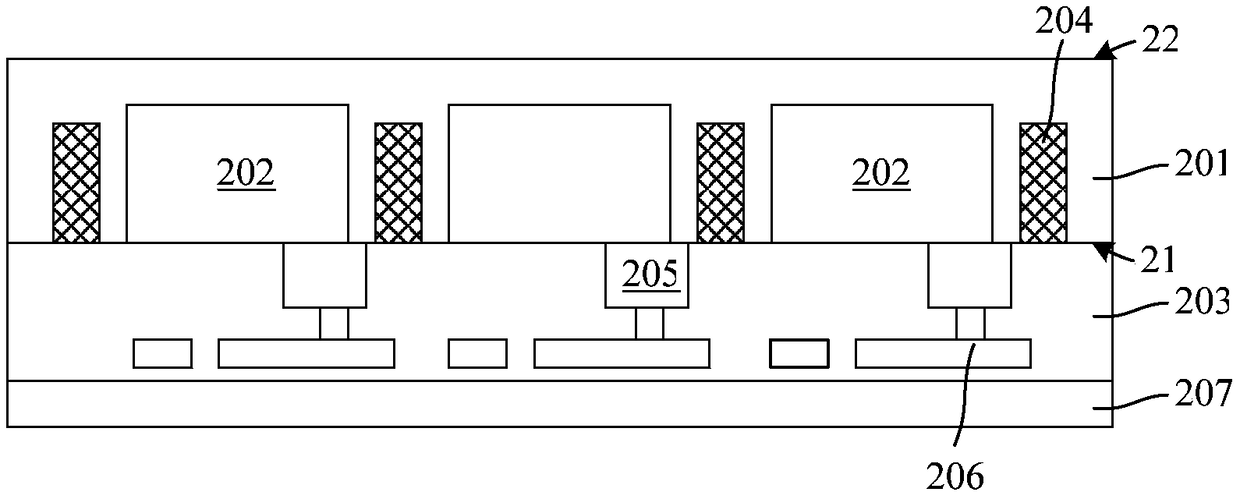

[0033] Figure 1-7 It is a structural schematic diagram of the formation process of the back-illuminated image sensor according to the first embodiment of the present invention.

[0034] refer to figure 1, provide a semiconductor substrate 201, the semiconductor substrate 201 includes a first side 21 and a second side 22 opposite to the first side 21, a number of discrete photosensitive regions are formed in the semiconductor substrate 201 of the first side 21 202 , the photosensitive region 202 is suitable for sensing light incident from the second side 22 .

[0035] The material of the semiconductor substrate 201 can be silicon (Si), germanium (Ge), or silicon germanium (GeSi), silicon carbide (SiC); it can also be silicon on insulator (SOI), germanium on insulator (GOI); or It can also be other materials, such as III-V group compounds such as gallium arsenide.

[0036] The semiconductor substrate 201 is doped with impurity ions, and different types of impurity ions are s...

no. 2 example

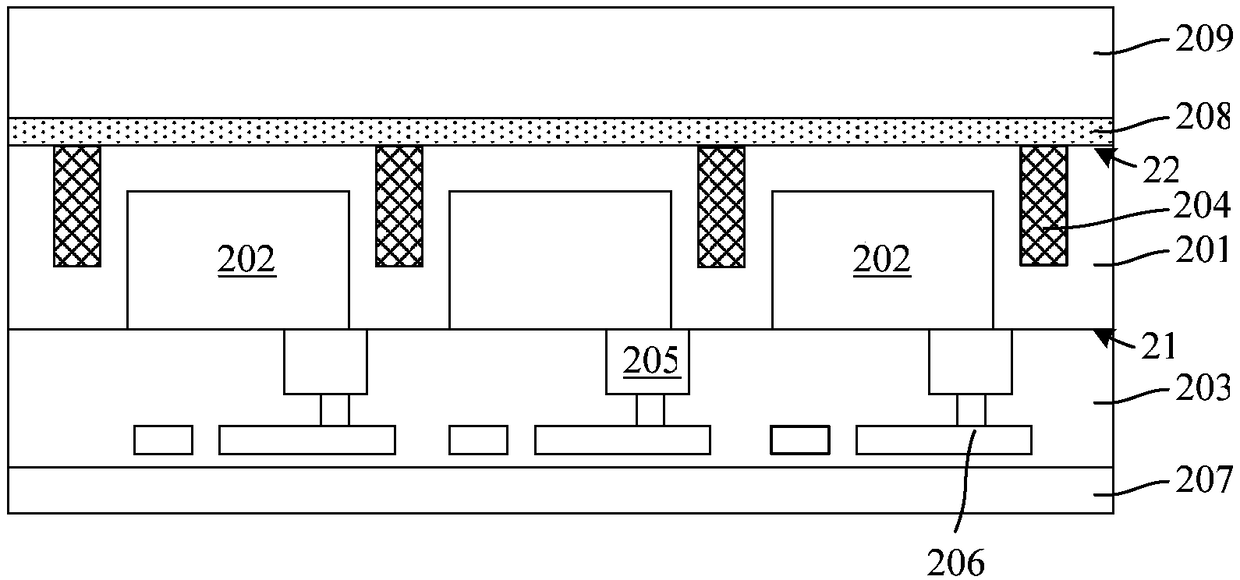

[0062] Figure 8-10It is a schematic structural diagram of the formation process of the back-illuminated image sensor according to the second embodiment of the present invention, Figure 8 is in figure 2 carried out on the basis of The difference between this embodiment and the previous embodiments is that a light-impermeable isolation region 220 is also formed in the first dielectric layer 208 and the semiconductor substrate 201 between the deep trench isolation structure 204 and the light-impermeable spacer 211 , Therefore, the opaque sidewall 211, the opaque isolation region 220 and the deep trench isolation structure 204 form a continuous structure (refer to Figure 10 ), which can further or better prevent the incident light from being transmitted to the adjacent photosensitive area 202, so as to further or better achieve the effect of preventing crosstalk.

[0063] refer to Figure 8 , forming a first dielectric layer 208 on the surface of the second side 22 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com