High-sensitivity toxic gas sensor and preparation method thereof

A poisonous gas, high-sensitivity technology, applied in the field of physical detection, can solve problems such as low detection limit, and achieve the effect of simple operation and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

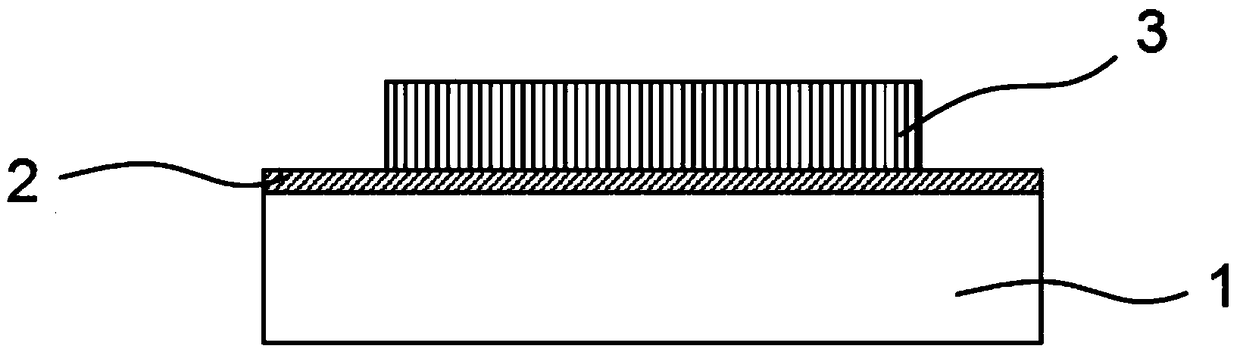

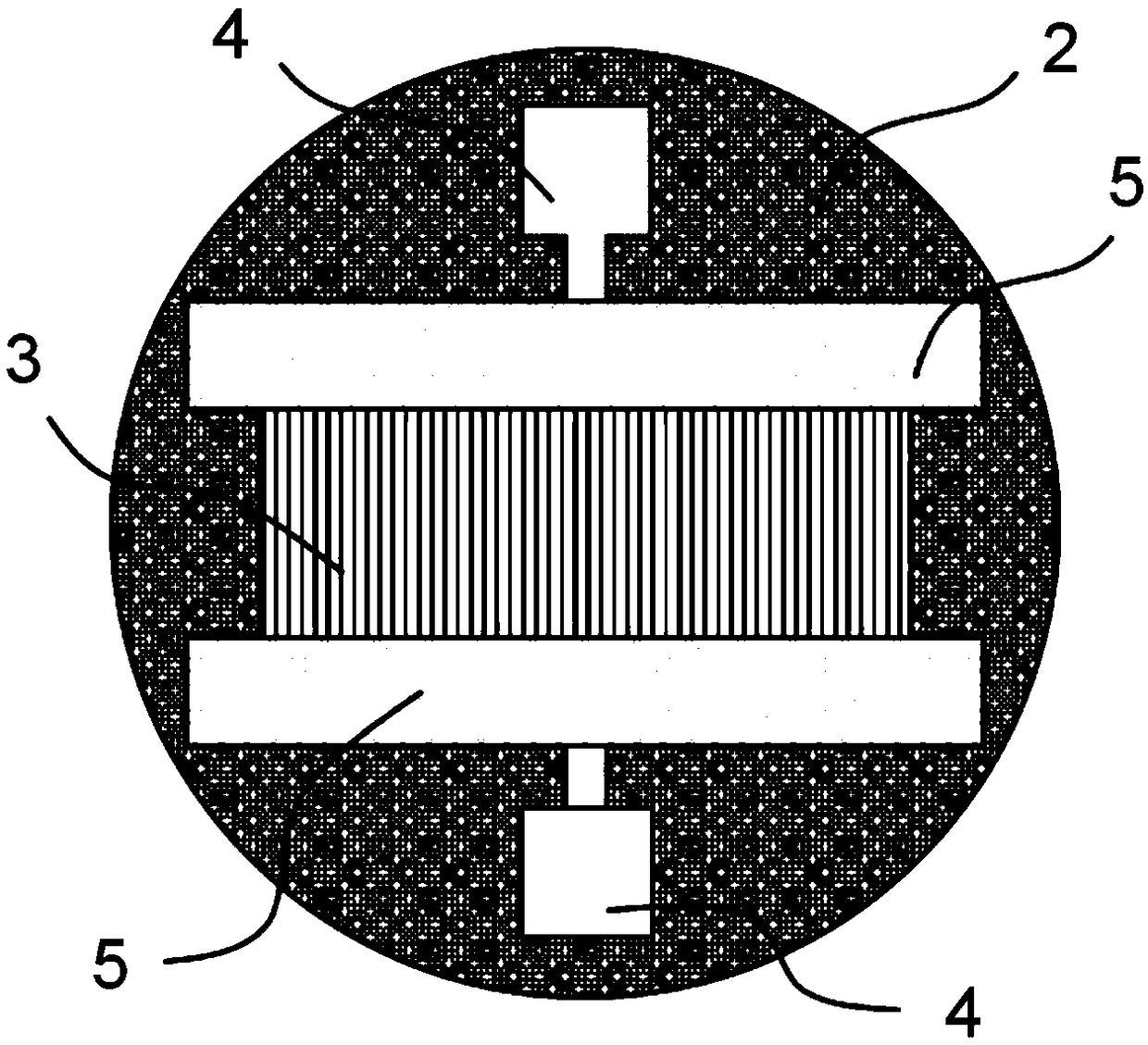

[0066] Embodiment 1: Preparation of highly sensitive toxic gas sensor

[0067] The preparation steps are as follows:

[0068] Step 1: Prepare silicon into a silicon wafer with a thickness of 500 μm as a semiconductor substrate, and deposit SiO with a thickness of 200 μm on the silicon wafer 2 barrier layer;

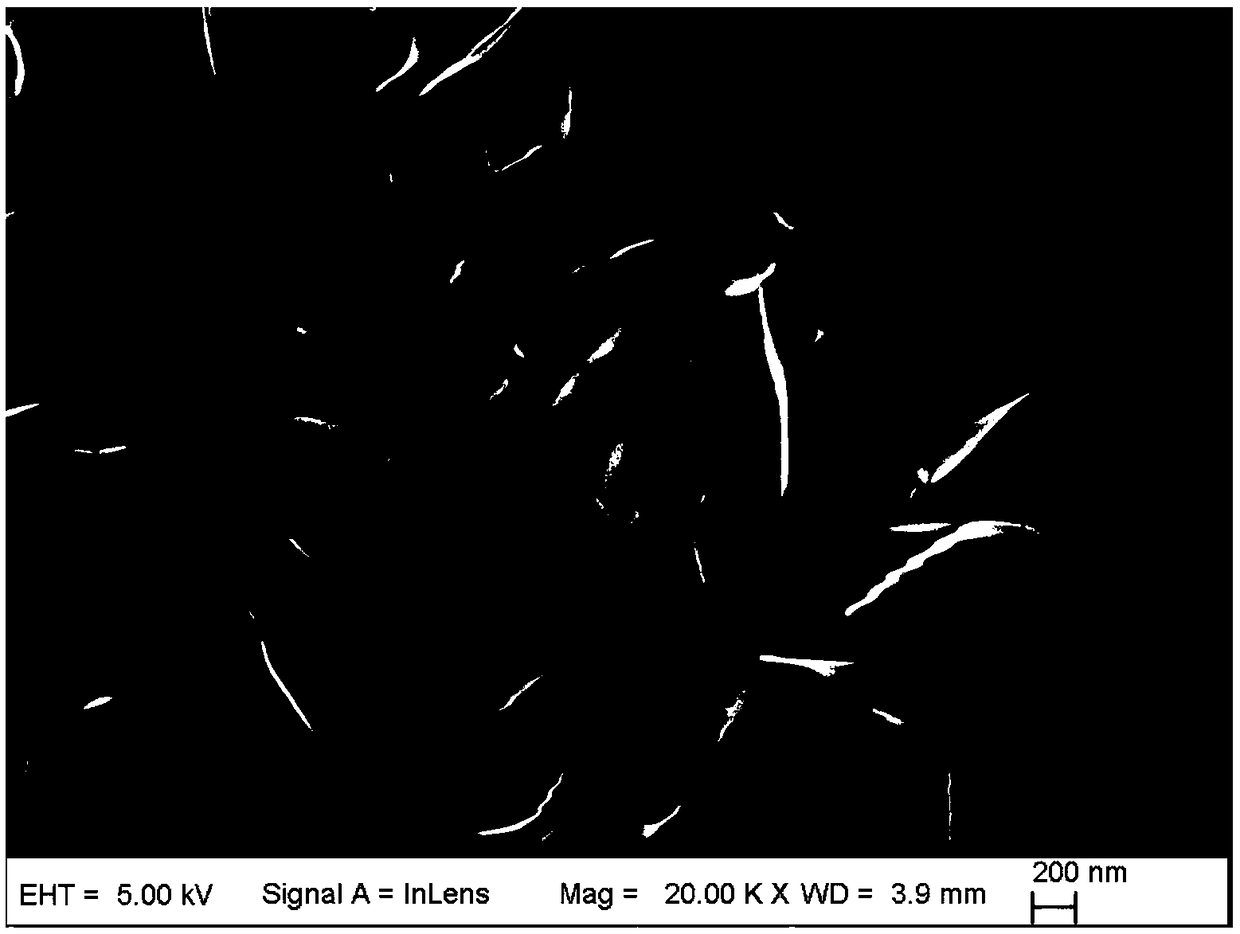

[0069] Step 2: SiO in Step 1 2 Evaporate a layer of molybdenum metal with a thickness of 10nm above the barrier layer, and carry out sulfuration treatment to this layer of metal molybdenum to obtain a molybdenum disulfide layer with a multilayer vertical arrangement structure with a thickness of about 15nm (during the sulfuration treatment, control the reaction The zone temperature is 770°C, and the heating temperature for sulfur powder is 220°C);

[0070] Step 3: Spin-coat photoresist on the molybdenum disulfide layer in step 2, and perform photolithography on the photoresist to obtain a template, and then etch the molybdenum disulfide layer through the template to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com