Compound sulfur remover for oil-gas fields

A technology for oil and gas fields and main agents, applied in the field of compound desulfurizers for oil and gas fields, can solve the problems of high risk, complicated operation of desulfurizers, low desulfurization efficiency, etc. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

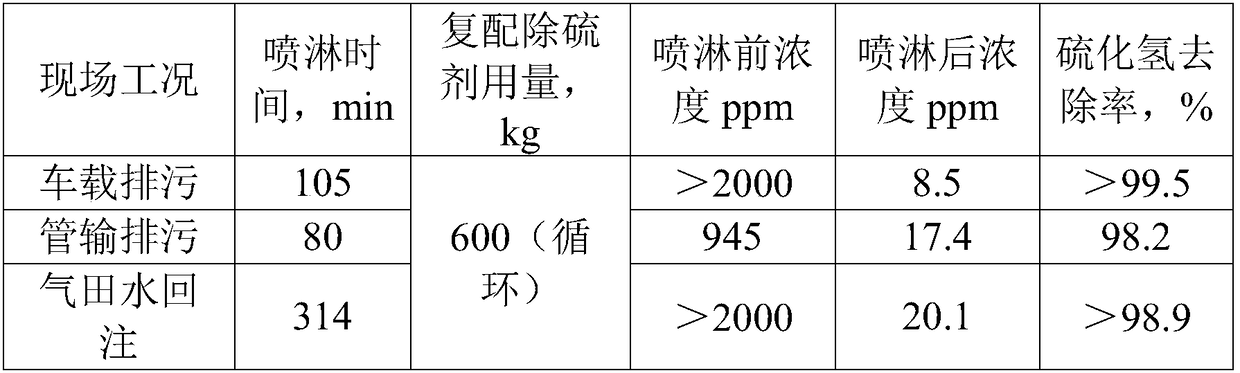

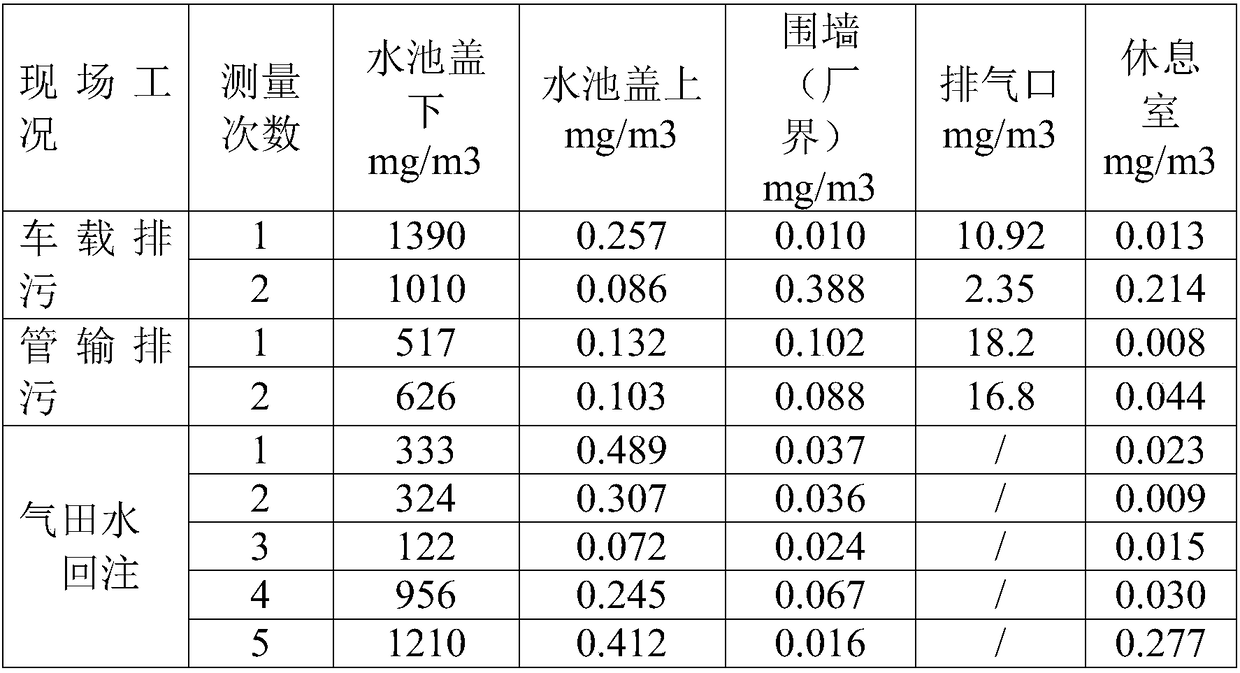

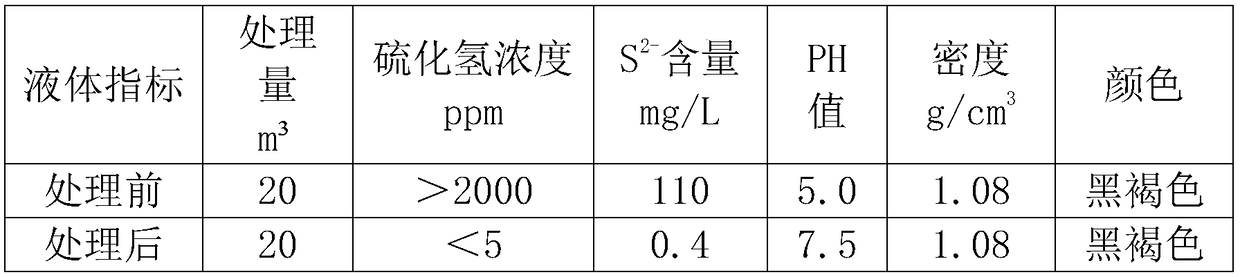

Examples

Embodiment 1

[0019] A compound desulfurizer for oil and gas fields, comprising the following components in mass percent:

[0020] Main agent: hydroxyethyl triazine 20%; auxiliary agent: monoethanolamine 10%; solvent: sulfolane 5%; scale inhibitor: polycarboxylic acid 2%; defoamer: methyl silicone oil 0.1%; the balance is water .

Embodiment 2

[0022] A compound desulfurizer for oil and gas fields, comprising the following components in mass percent:

[0023] Main agent: 30% mixture of hydroxyethyl triazine and hydroxypropyl triazine; auxiliary agent: 12% mixture of monoethanolamine and diethanolamine; solvent: 8% mixture of sulfolane and dimethyl sulfoxide; scale inhibitor: 4% mixture of polycarboxylic acid and organic phosphonate; defoamer: 0.1% mixture of methyl silicone oil and ethyl silicone oil; the balance is water.

Embodiment 3

[0025] A compound desulfurizer for oil and gas fields, comprising the following components in mass percent:

[0026] Main agent: 32% mixture of hydroxyethyl triazine, ethyl triazine and propyl triazine; auxiliary agent: 15% mixture of monoethanolamine, diethanolamine, triethanolamine; solvent: solvent of sulfolane and dimethyl sulfoxide 10%; scale inhibitor: 5% mixture of polycarboxylic acid and organic phosphonate; defoamer: 0.2% mixture of methyl silicone oil, ethyl silicone oil and phenyl silicone oil; the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com