Environment-friendly coal-water slurry and its production method

A coal-water slurry, environment-friendly technology, applied in the field of coal chemical industry, can solve the problem of high production cost, and achieve the effect of low cost, good fluidity and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

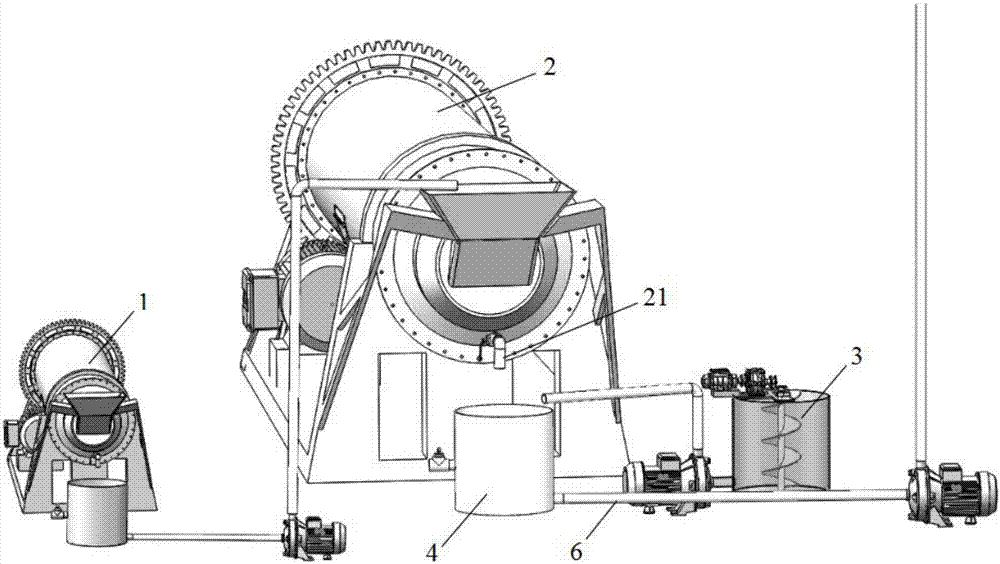

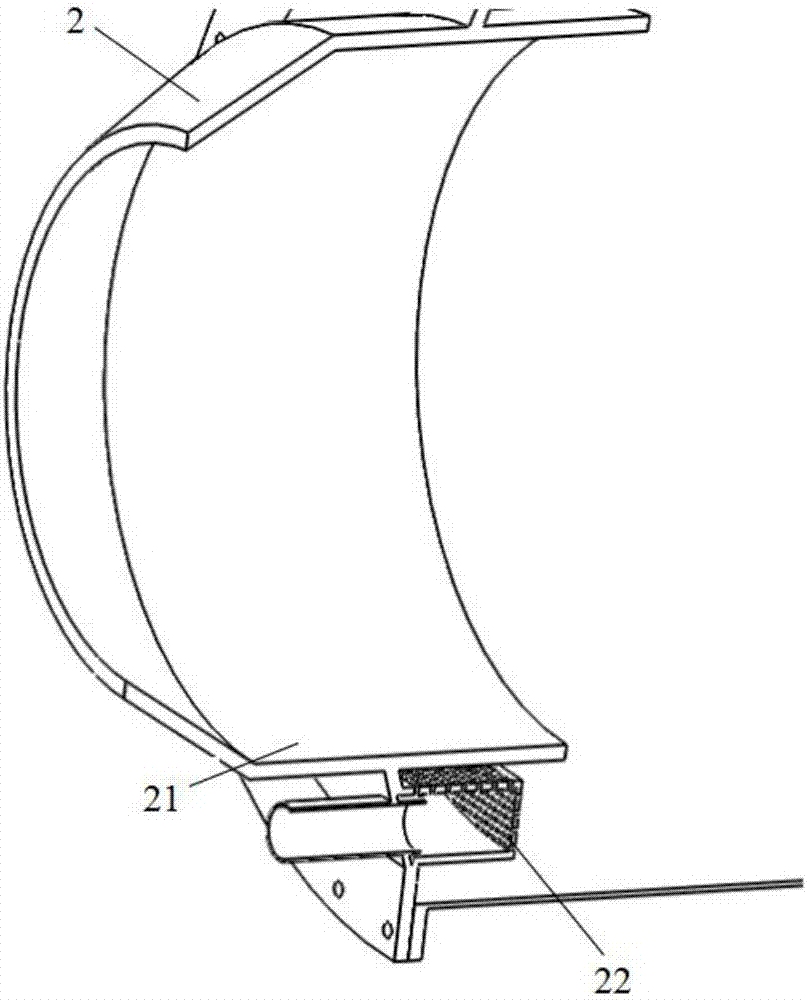

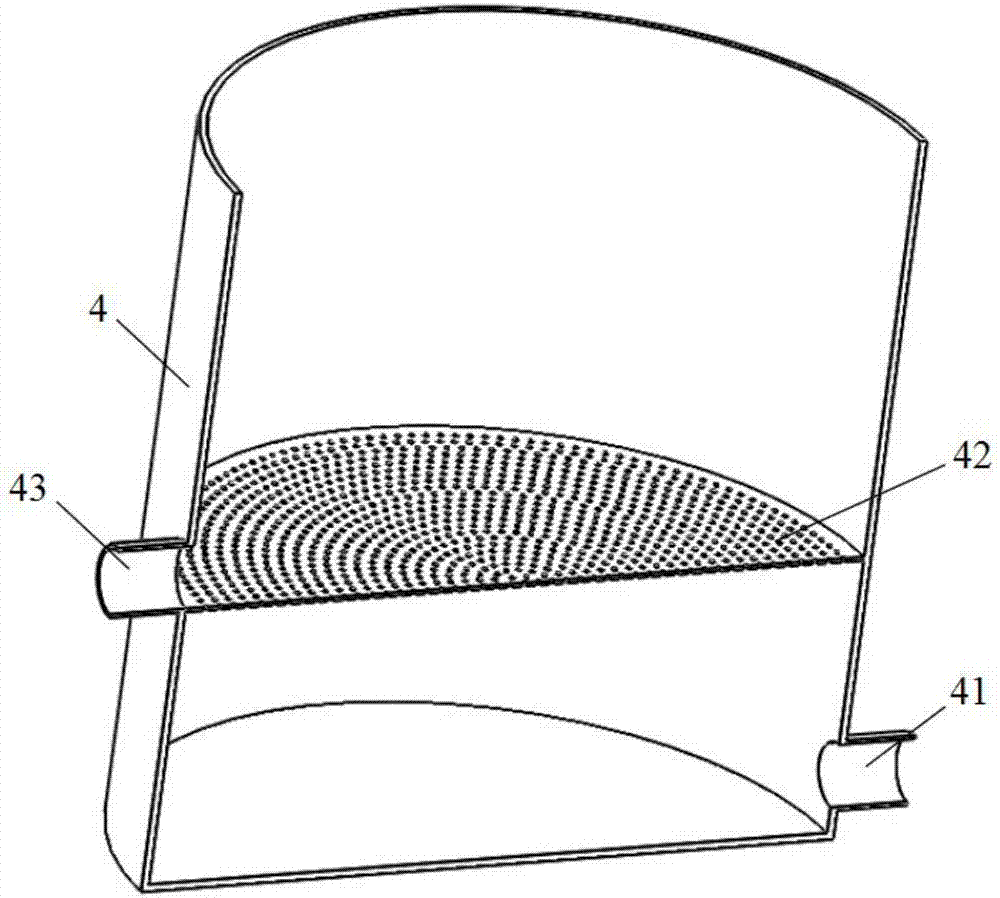

Method used

Image

Examples

Embodiment 1

[0053] The environment-friendly coal-water slurry includes: 600g of long-flame coal, 350g of water, 60g of weathered coal-water slurry with dispersing effect, and 4g of stabilizer.

[0054] The production method of above-mentioned environment-friendly type coal-water slurry is as follows:

[0055] Step 1: 120g of weathered coal with a humic acid content of 42%, 30g of NaOH for industrial use, 0.8g of polyoxyethylene sorbitol, 1g of sodium benzenesulfonate, and 250g of water are added to the coal-water slurry ball mill through the feed port. Under the condition of 50°C, the ball milling slurry was made for 1.5 hours. After ball milling, the proportion of weathered coal particles with a particle size of less than 200 mesh was 85%, and the weathered coal-water slurry with dispersing effect was obtained. The weathered coal-water slurry with dispersing effect passed through the outlet Feed mouth enters in the dispersant storage tank and stores, and the weathered coal-water slurry w...

Embodiment 2

[0062] The environment-friendly coal-water slurry includes: 650g of gas coal, 350g of water, 60g of weathered coal-water slurry with dispersing effect, and 5g of stabilizer.

[0063] The production method of above-mentioned environment-friendly type coal-water slurry is as follows:

[0064] Step 1: Add 140g of weathered coal with a humic acid content of 38%, 28g of NaOH for industrial use, 0.9g of polyoxyethylene sorbitol, 1.2g of sodium benzenesulfonate, and 260g of water into the coal-water slurry ball mill through the feed port. Under the condition of 50°C, ball milling pulping for 2 hours, after ball milling, the proportion of weathered coal particles with particle size less than 200 mesh is 90%, and weathered coal-water slurry with dispersing effect is obtained, and the weathered coal-water slurry with dispersing effect passes through the outlet Feed mouth enters in the dispersant storage tank and stores, and the weathered coal-water slurry with dispersing effect obtained...

Embodiment 3

[0071] The environment-friendly coal-water slurry includes: 650g of long-flame coal, 350g of water, 70g of weathered coal-water slurry with dispersing effect, and 8g of stabilizer.

[0072] The production method of above-mentioned environment-friendly type coal-water slurry is as follows:

[0073] Step 1: 120g of weathered coal with a humic acid content of 45%, 26g of industrial NaOH, 0.7g of polyoxyethylene sorbitol, 0.9g of sodium benzenesulfonate, and 230g of water are added to the coal-water slurry ball mill through the feed port. Under the condition of 50 ℃, ball milling pulping for 1 hour, after ball milling, the proportion of weathered coal particles with particle size less than 200 mesh is 85%, and the weathered coal water slurry with dispersing effect is obtained, and the weathered coal water slurry with dispersing effect passes through the outlet Feed mouth enters storage in the dispersant storage tank, gets the weathered coal-water slurry with dispersing effect that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com