Long afterglow ceramic with non-cracking glazed surface and preparation process

A production process and long afterglow technology, applied in clay products, other household appliances, applications, etc., can solve the problems of influence, cracks on the glaze of luminescent ceramics, and reduce the aesthetics of luminescent ceramics, achieve good bonding and reduce firing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

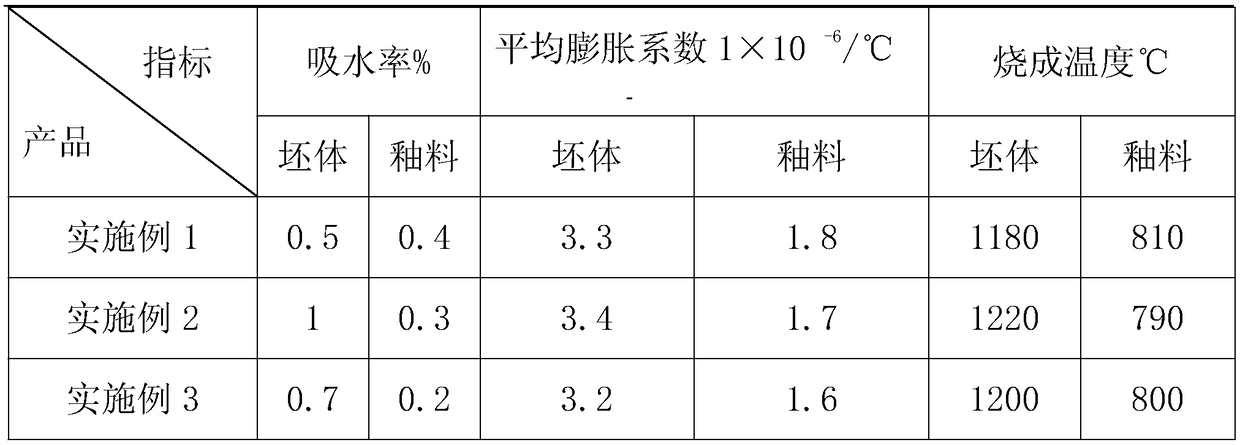

Embodiment 1

[0050] A long afterglow ceramic with no cracks in the glaze, including a body and a glaze;

[0051] The glaze includes the following raw materials in parts by weight: 1 part of low-temperature glaze water and 22 parts of aluminate long afterglow material.

[0052] The green body includes the following raw materials in parts by weight: 35 parts of Dehua clay, 6 parts of Dehua Zimujie soil, 32 parts of Dehua low temperature stone, 25 parts of Fujian Yongan albite, 20 parts of perilla pyroxene, 15 parts of sepiolite 10 parts, 10 parts amphibolite, and 10 parts granulite.

[0053] The low-temperature glaze water includes the following raw materials in parts by weight: 18 parts of Australian spodumene, 13 parts of talc, 7 parts of limestone, 10 parts of borax, 32 parts of boric acid, 15 parts of Dehua quartz, 12 parts of sillimanite, 1 part of kaolin, zinc oxide 3 copies.

[0054] And the chemical composition of the low-temperature glaze water is as follows: Li 2 O: 1.4%, Na 2 ...

Embodiment 2

[0070] A long afterglow ceramic with no cracks in the glaze, including a body and a glaze;

[0071] The glaze includes the following raw materials in parts by weight: 1 part of low-temperature glaze water and 28 parts of aluminate long afterglow material.

[0072] The green body includes the following raw materials in parts by weight: 30 parts of Dehua clay, 10 parts of Dehua Zimujie soil, 28 parts of Dehua low temperature stone, 35 parts of Fujian Yongan albite, 25 parts of perilla pyroxene, 12 parts of sepiolite 15 parts of amphibolite and 6 parts of granulite.

[0073] The low-temperature glaze water includes the following raw materials in parts by weight: 22 parts of Australian spodumene, 9 parts of talc, 5 parts of limestone, 15 parts of borax, 28 parts of boric acid, 20 parts of Dehua quartz, 8 parts of sillimanite, 5 parts of kaolin, zinc oxide 1 serving.

[0074] And the chemical composition of the low-temperature glaze water is as follows: Li 2 O: 1.6%, Na 2 O: 2....

Embodiment 3

[0090] A long afterglow ceramic with no cracks in the glaze, including a body and a glaze;

[0091] The glaze includes the following raw materials in parts by weight: 1 part of low-temperature glaze water and 25 parts of aluminate long afterglow material.

[0092] The green body includes the following raw materials in parts by weight: 32 parts of Dehua clay, 8 parts of Dehua Zimujie soil, 30 parts of Dehua low temperature stone, 30 parts of Fujian Yongan albite, 22 parts of perilla pyroxene, 13 parts of sepiolite 12 parts of amphibolite and 8 parts of granulite.

[0093] The low-temperature glaze water includes the following raw materials in parts by weight: 20 parts of Australian spodumene, 11 parts of talc, 6 parts of limestone, 13 parts of borax, 30 parts of boric acid, 18 parts of Dehua quartz, 10 parts of sillimanite, 3 parts of kaolin, zinc oxide 2 servings.

[0094] And the chemical composition of the low-temperature glaze water is as follows: Li 2 O: 1.5%, Na 2 O: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com