Cold resistant and flame retardant antistatic conveyor belt cover rubber and conveyor belt

A conveyor belt and anti-static technology, which is applied in the field of covering rubber, can solve the problems of poor cold resistance and flame retardant effect of conveyor belts, and achieve the effects of improving anti-static ability, physical performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

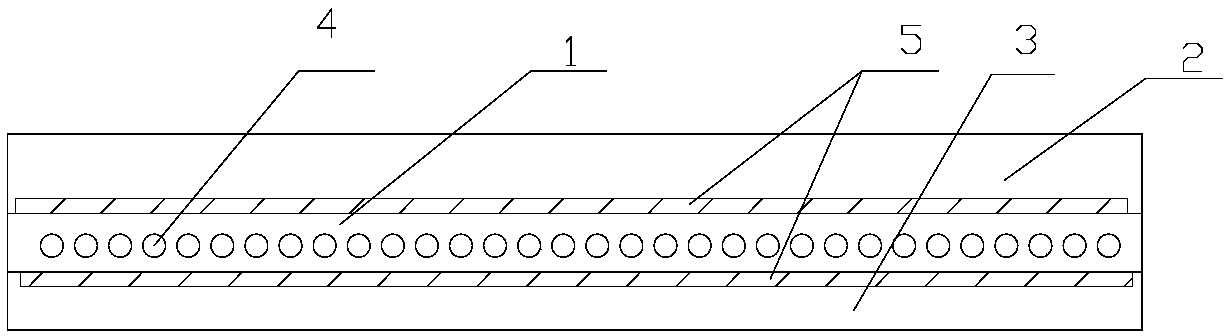

Image

Examples

Embodiment 1

[0024] Embodiment 1: A kind of cold-resistant flame-retardant anti-static conveyor belt covering rubber, formula by weight, 35 parts of natural rubber, 40 parts of butadiene rubber, 20 parts of neoprene rubber, 20 parts of conductive carbon black, 25 parts of high wear-resistant carbon black 10 parts of antimony trioxide, 5 parts of chlorinated paraffin, 8 parts of ammonium polyphosphate, 5 parts of flame retardant softener, 1 part of vulcanizing agent, 1 part of vulcanization accelerator, 3 parts of zinc oxide, 1 part of magnesium oxide, rare earth 10 parts of oxide, 1 part of stearic acid, 2 parts of antioxidant, 1 part of antioxidant.

[0025] A method for preparing a cold-resistant, flame-retardant and anti-static conveyor belt covering glue, the steps are as follows,

[0026] a, 35 parts of natural rubber, 40 parts of butadiene rubber, 20 parts of chloroprene rubber, 10 parts of rare earth oxides, and 1 part of antioxidant are mixed in the internal mixer for 3 minutes, an...

Embodiment 2

[0032] A cold-resistant, flame-retardant and anti-static conveyor belt covering rubber, the formula is by weight, 40 parts of natural rubber, 50 parts of butadiene rubber, 25 parts of neoprene rubber, 25 parts of conductive carbon black, 30 parts of high wear-resistant carbon black, trioxide 12 parts of antimony, 8 parts of chlorinated paraffin, 12 parts of ammonium polyphosphate, 7 parts of flame retardant softener, 1.5 parts of vulcanizing agent, 1.5 parts of vulcanization accelerator, 5 parts of zinc oxide, 1.5 parts of magnesium oxide, 13 parts of rare earth oxide , 1.5 parts of stearic acid, 3 parts of antioxidant, 1.5 parts of antioxidant.

[0033] A method for preparing a cold-resistant, flame-retardant and anti-static conveyor belt covering glue, the steps are as follows,

[0034] a, 40 parts of natural rubber, 50 parts of butadiene rubber, 25 parts of chloroprene rubber, 13 parts of rare earth oxides, and 1.5 parts of antioxidant were mixed in the internal mixer for 4...

Embodiment 3

[0039]Embodiment 3: A kind of cold-resistant, flame-retardant and anti-static conveyor belt covering rubber, the formula is by weight, 50 parts of natural rubber, 60 parts of butadiene rubber, 30 parts of neoprene rubber, 30 parts of conductive carbon black, 35 parts of high wear-resistant carbon black 15 parts of antimony trioxide, 10 parts of chlorinated paraffin, 15 parts of ammonium polyphosphate, 10 parts of flame retardant softener, 2 parts of vulcanizing agent, 2 parts of vulcanization accelerator, 6 parts of zinc oxide, 2 parts of magnesium oxide, rare earth 16 parts of oxide, 2 parts of stearic acid, 4 parts of antioxidant, 2 parts of antioxidant.

[0040] A method for preparing a cold-resistant, flame-retardant and anti-static conveyor belt covering glue, the steps are as follows,

[0041] a, 50 parts of natural rubber, 60 parts of butadiene rubber, 30 parts of chloroprene rubber, 16 parts of rare earth oxides, and 2 parts of antioxidant were mixed in the internal mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com