Flame-retardant polyethylene cable material with high elongation rate and cracking resistance

A flame-retardant polyethylene and anti-cracking technology, applied in the field of cable material manufacturing, can solve the problems of poor affinity between polyethylene resin and inorganic flame retardants, poor cracking resistance of polyethylene cable materials, and reduced thermal deformation temperature, etc. Effects of physical and mechanical properties, excellent crack resistance, high-speed extrusion processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

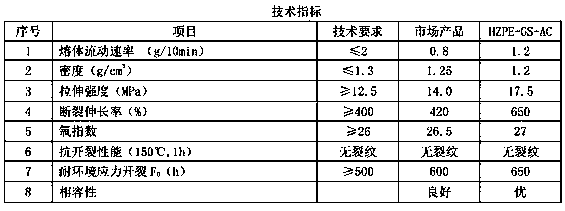

[0008] Example 1: A high-elongation anti-cracking flame-retardant polyethylene cable material, weighed 70 parts of polyethylene resin, 20 parts of ethylene-vinyl acetate resin, 8 parts of ethylene octene copolymer, 30 parts of magnesium hydroxide, organic resistance 20 parts of fuel, 1 part of coupling agent, 1 part of antioxidant 1010, 1 part of lubricant, using double-roll proofing temperature 165 ℃, time 5 minutes. The finally obtained high-speed extrusion anti-cracking flame-retardant polyethylene cable material of the present invention. The tensile strength is 17.5MPa, the elongation at break is 650%, the crack resistance (150℃, 1h) does not crack, and the oxygen index OI=27. The unit of weight per serving is grams or kilograms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com