Preparation method of continuous carbon fiber polyetheretherketone composite material

A technology of polyetheretherketone and composite materials, which is applied in the field of carbon fiber reinforced thermoplastic composite materials, can solve the problems of difficulty in achieving fiber dispersion and impregnation effects, incomplete melting and impregnation of polyetheretherketone resin, and high preparation costs, and achieves good results. Interface binding effect, improved impregnation effect, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Surface treatment of carbon fiber (CF):

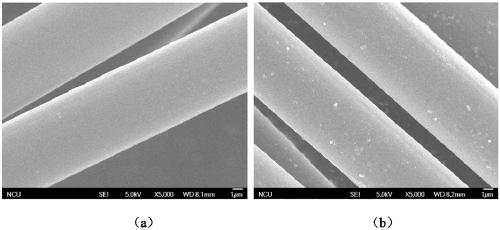

[0031] The carbon fiber is treated for 10 hours by means of acetone condensation and reflux to desize its surface and increase its surface roughness (such as figure 1 shown), improving the impregnation effect with the PEEK matrix. The desizing carbon fiber is cleaned and dried, and the bundled carbon fiber is repeatedly brushed with a plastic brush several times, and then the polyetheretherketone (PEEK) powder is adsorbed by electrostatic action to coat the surface of the carbon fiber.

[0032] (2) Preparation of prefabricated CF / PEEK composite material:

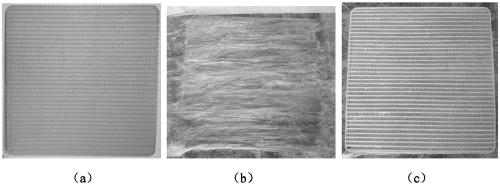

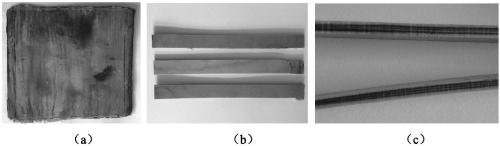

[0033] The polyetheretherketone wire is printed into a 120mm*120mm*1mm grid-like PEEK sheet using 3D printing technology. The carbon fiber (CF) bundle evenly wrapped by PEEK powder is spread on the grid-shaped PEEK plate along the fiber direction to make it spread into a 120mm*120mm square. At the same time, a certain tension is applied to both ends of the carbon fiber b...

Embodiment 2

[0037] (1) Surface treatment of carbon fiber (CF):

[0038] The carbon fiber was treated for 10 h by condensing and refluxing acetone to desize its surface. The desized carbon fiber is cleaned and dried, and the bundled carbon fiber is repeatedly brushed with a plastic brush for several times, and then the polyetheretherketone powder is adsorbed by electrostatic action to coat the surface of the carbon fiber.

[0039] (2) Preparation of prefabricated CF / PEEK composite material:

[0040] The polyetheretherketone wire is printed into a 120mm*120mm*1mm grid-like PEEK sheet using 3D printing technology. Spread the carbon fiber bundle evenly wrapped by PEEK powder on the grid-shaped PEEK sheet along the fiber direction to make it spread into a 120mm*120mm square. Layers of grid-shaped PEEK sheets, and then alternately lay two layers of carbon fiber and PEEK sheets to form a three-layer prefabricated CF / PEEK composite material.

[0041] (3) Hot compression molding of CF / PEEK comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com