Surface-modified SiC nano wire, preparation method and applications thereof

A surface modification and nanowire technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as poor interface bonding, low surface activity, and difficult dispersion, and achieve low cost, The effect of easy control and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode 1: The method for surface modification of SiC nanometers provided in this implementation mode is realized through the following steps:

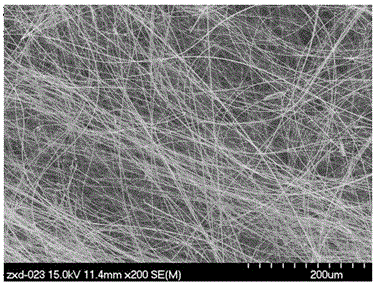

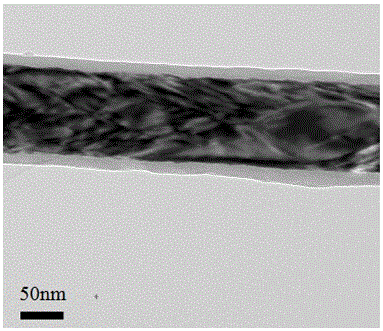

[0019] Place the SiC nanowires in a tubular sintering furnace or a heating device that can protect the atmosphere, feed a mixed flow of oxygen and nitrogen, control the oxygen flow rate to 5-500ml / min, and the nitrogen flow rate to 5-1000ml / min, and then start heating. Heating from room temperature to 700-1400° C., controlling the heating rate to 5-20° C. / min, and holding time to 30-120 minutes can obtain the surface-modified SiC nanowires. The surface-modified SiC nanowire is a one-dimensional nanomaterial with a core-shell structure, the core is SiC, and the outer layer is SiO 2 , SiO 2 Closely coated on the outside of SiC to form a dense coating layer, in which SiO 2 The cladding layer is amorphous, and the bonding at the interface is close bonding at the atomic scale. According to the diameter scale ...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that SiO 2 The layer thickness is 10~200nm.

specific Embodiment approach 3

[0022] Specific implementation mode three: the difference between this implementation mode and specific implementation modes one and two is that SiO 2 The layer thickness is 10~100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com