A kind of pla-tps nanofibrous film and its preparation method and application

A nanofiber membrane, pla-tps technology, applied in the preparation of PLA-TPs nanofiber membrane, in the field of PLA-TPs nanofiber membrane, to achieve enhanced adsorption capacity, simple operation, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

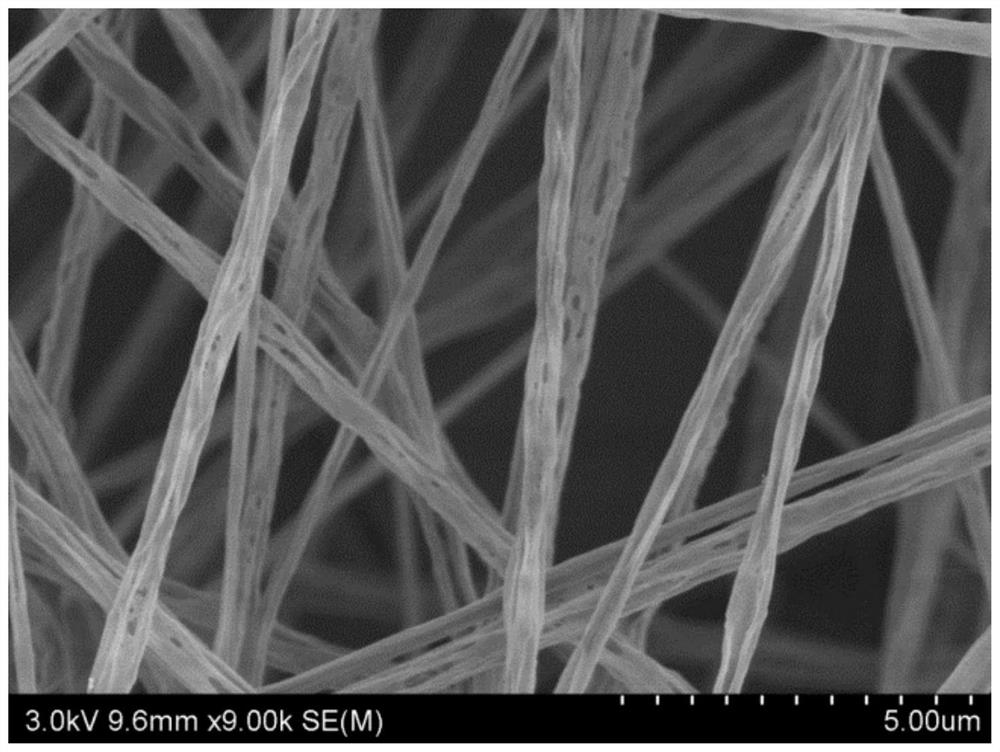

Image

Examples

Embodiment 1

[0020] A preparation method of PLA-TPs nanofiber membrane, comprising the steps of:

[0021] (1) Add a DCM / DMF mixed solution with a mass ratio of 8:2 to the brown ground bottle, then weigh a certain mass of polylactic acid, add it to the mixed solution, and then put the brown ground bottle on a magnetic stirrer Stir at a constant speed for 2-4 hours until the solute is completely dissolved, the solution is clear and transparent, and a polylactic acid solution with a concentration of 6wt%-8wt% is obtained;

[0022] (2) Weigh a certain amount of tea polyphenols according to the mass ratio of tea polyphenols to polylactic acid of 0.04:1, add them to the above polylactic acid solution, and then place the prepared mixed solution on a magnetic stirrer and stir at a constant speed for 24 hours , to obtain a uniform spinning solution;

[0023] (3) Start the spinning machine, control the temperature of the experimental environment at 20°C-30°C, and the relative humidity at 45%-65%, a...

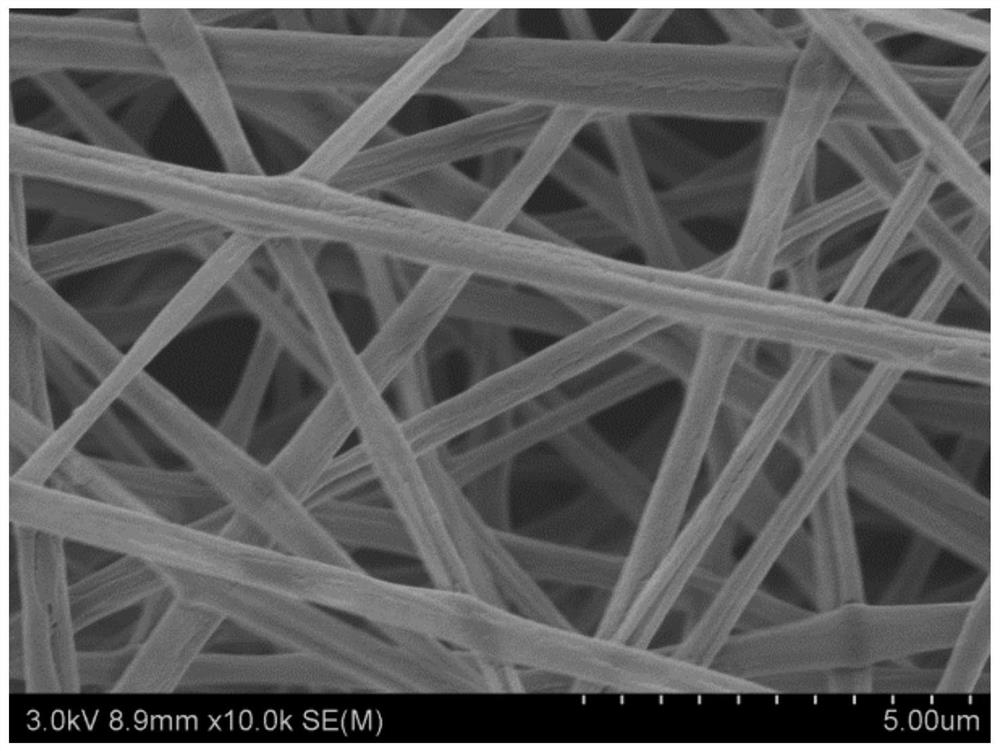

Embodiment 2

[0027] A method for preparing a PLA-TPs nanofiber membrane, which differs from Example 1 only in that the mass ratio of the solvent is DCM:DMF=7:3.

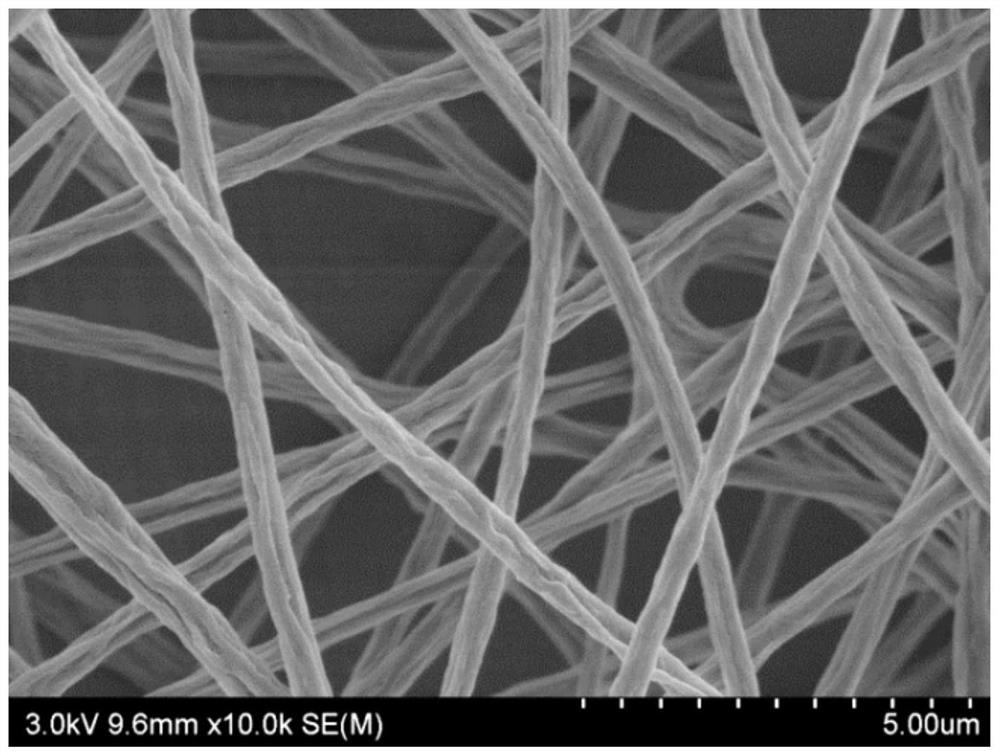

Embodiment 3

[0029] A method for preparing a PLA-TPs nanofiber membrane, the difference from Example 1 is that the mass ratio of tea polyphenols to polylactic acid is 0.125:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com