Degradable composite material prepreg tape, and preparation method and use thereof

A technology of composite material and prepreg tape, which is applied in the field of composite material prepreg tape and its preparation, can solve the problems of small fiber length and diameter of natural fiber reinforced materials, prone to brittle fracture, limited reinforcement effect, etc., and achieve excellent impact resistance , less environmental hazards, and less reduction in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of modified PBAT:

[0059] Put 82 parts of PBAT resin, 10 parts of compatibilizer PCL, 3 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate as weathering agent, and 5 parts of release agent silicone oil in a mixer Mixed in medium for 7 minutes, fully mixed and then added to a twin-screw extruder to extrude and pelletize. The screw speed is 80r / min, and the extrusion temperature is 115°C to obtain a modified PBAT resin.

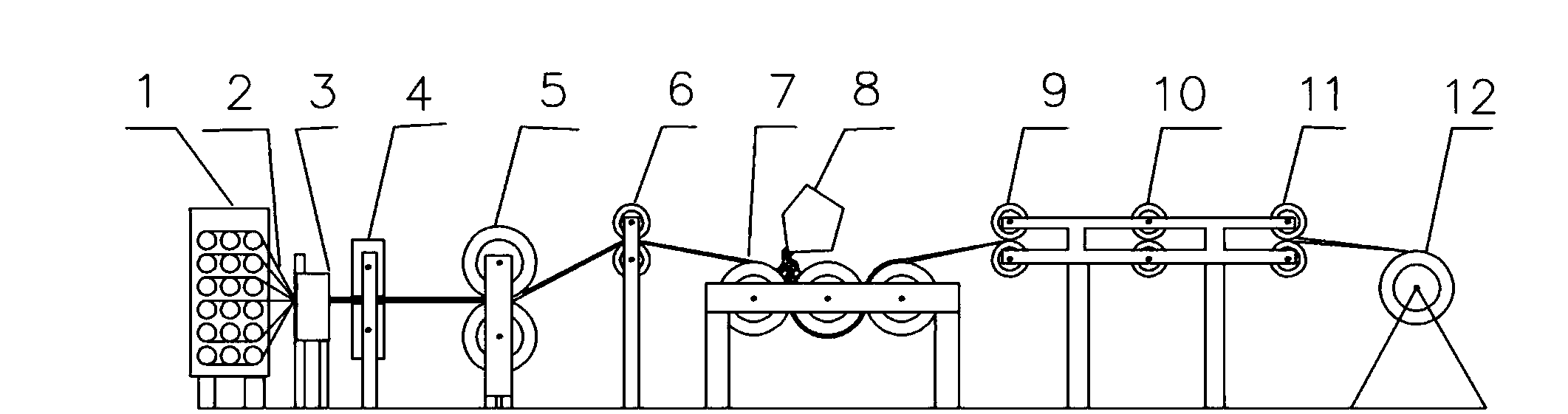

[0060] (2) if figure 1 As shown, 120 volumes of jute fibers are drawn from the creel 1, and untwisted through the untwisting machine 3, in a loose and expanded form;

[0061] (3) The jute fiber after the untwisting is drawn out from the arrangement and warping device 4, so that it is evenly distributed;

[0062] (4) The jute fiber enters the pressing roller 5 and the tension control device 6 successively. After these steps, the jute fiber becomes a thin layer with a thickness of 0.5mm;

[0063] (5) The jute fiber is fully contac...

Embodiment 2

[0068] (1) Preparation of modified PBAT:

[0069] Take 88 parts of PBAT resin, 8 parts of PHA, 2 parts of weather resistance agent 2,4-dihydroxy-benzophenone, and 2 parts of mold release agent polyethylene glycol and mix them in a mixer for 4 minutes, and then add them to twin-screw extrusion after fully mixing In the machine, pelletizing was extruded, the screw speed was 75r / min, and the extrusion temperature was 115°C to obtain the modified PBAT resin.

[0070] (2) if figure 1 As shown, 80 rolls of flax fiber are drawn from the creel 1, and untwisted by the untwisting machine 3, showing a loose and expanded form;

[0071] (3) Lead out the untwisted flax fibers from the arrangement and warping device 4 to make them evenly distributed;

[0072] (4) The flax fiber enters the pressing roller 5 and the tension control device 6 successively. After these steps, the flax fiber becomes a thin layer with a thickness of 0.5mm;

[0073] (5) Flax fibers are fully contacted and impregn...

Embodiment 3

[0078] (1) Preparation of modified PBAT:

[0079] Take 90 parts of PBAT resin, 5 parts of compatibilizer PEG, 1 part of weather resistance agent 2-(2'-hydroxy-5'-)benzotriazole, 4 parts of release agent low molecular weight polyethylene, and mix in a mixer for 6 minutes , mixed and added to a twin-screw extruder, extruded and pelletized, the screw speed is 75r / min, and the extruder head temperature is 118°C.

[0080] (2) if figure 1 As shown, 150 rolls of jute fibers are drawn from the creel 1, and untwisted through the untwisting machine 3, in a loose and expanded form;

[0081] (3) The jute fiber after the untwisting is drawn out from the arrangement and warping device 4, so that it is evenly distributed;

[0082] (4) The jute fiber enters the pressing roller 5 and the tension control device 6 successively. After these steps, the jute fiber becomes a thin layer with a thickness of 0.4mm;

[0083] (5) The jute fiber is fully contacted and impregnated with the PBAT resin pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com