Textile cloth wetting device

A wetting technology for textile fabrics, applied in textiles and papermaking, spray/jet textile material treatment, fiber treatment, etc., can solve problems such as poor wetting effect of textile fabrics, low tensile strength of textile fabrics, and affecting production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

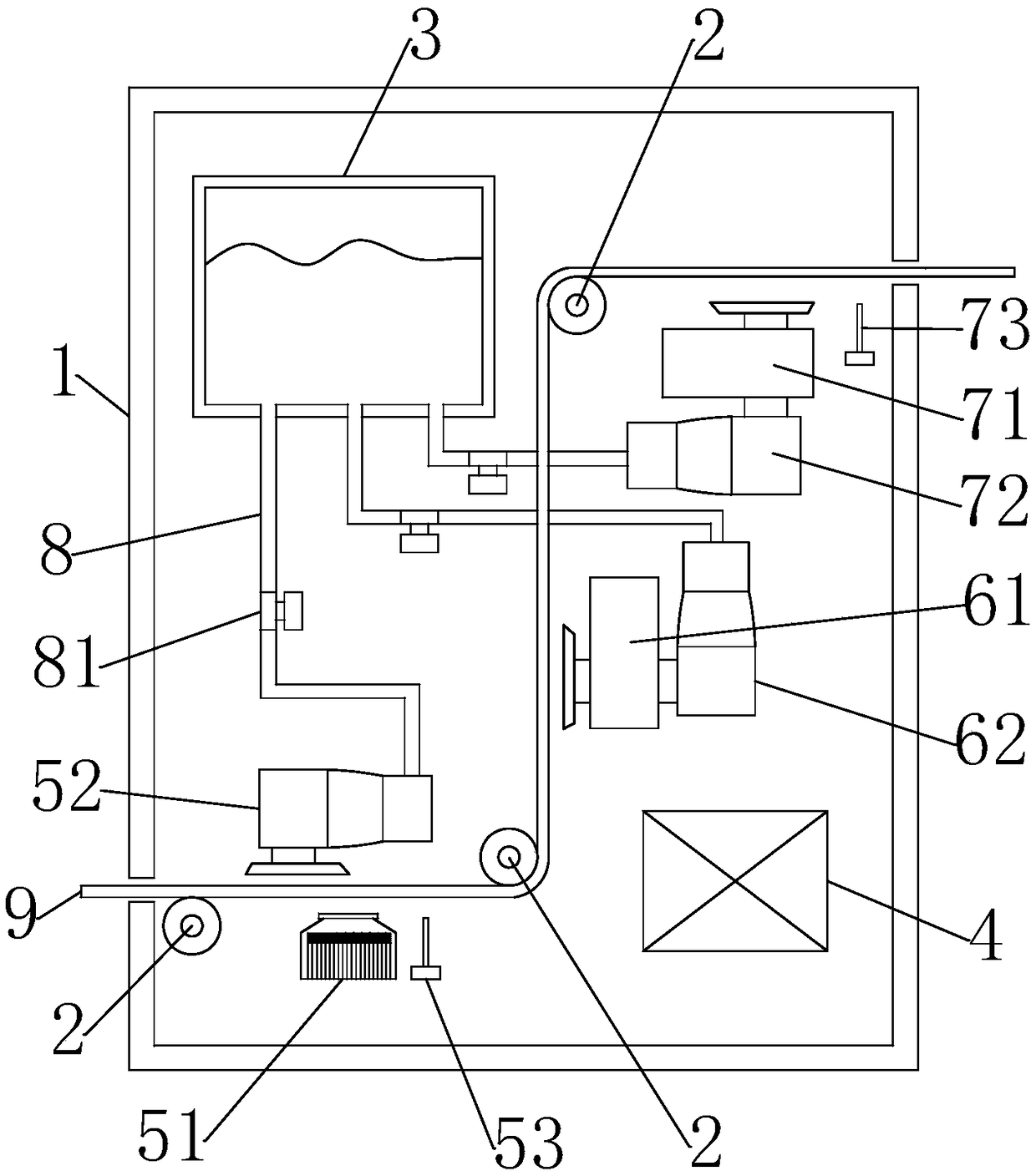

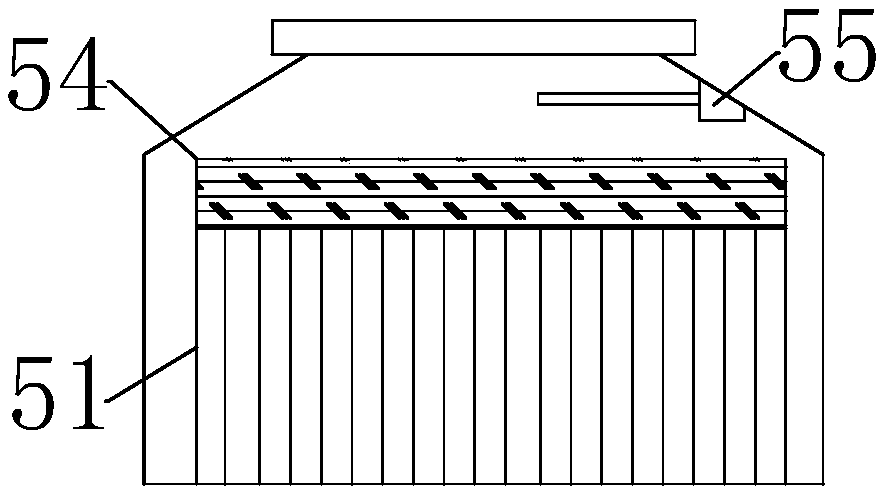

[0017] Such as Figure 1 to Figure 2 As shown, a wetting device for textile cloth includes a box body 1, and as an improvement of the present invention, it also includes a drive motor arranged in the box body 1, a cloth transport roller 2, a wetting device, a water storage tank 3 and a controller 4 , the wetting device comprises a first wetting device, a second wetting device and a third wetting device, the first wetting device comprises a low temperature plasma generator 51, the first atomizer 52 and an ion sensor 53, the second wetting device The device includes a rare earth additive package 61 and a second atomizer 62, and the third wetting device includes a redox agent package 71, a third atomizer 72, and a humidity sensor 73....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com