Optical fiber ring for optical fiber gyro and optical fiber ring processing method

A fiber optic gyroscope and processing method technology, which is applied to Sagnac effect gyroscopes, gyroscopes/steering sensing equipment, measuring devices, etc., can solve the problem of poor Shupe error suppression performance, large error signal, and fiber can not be fully wound, etc. problem, to achieve the effect of small temperature error and reduced influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

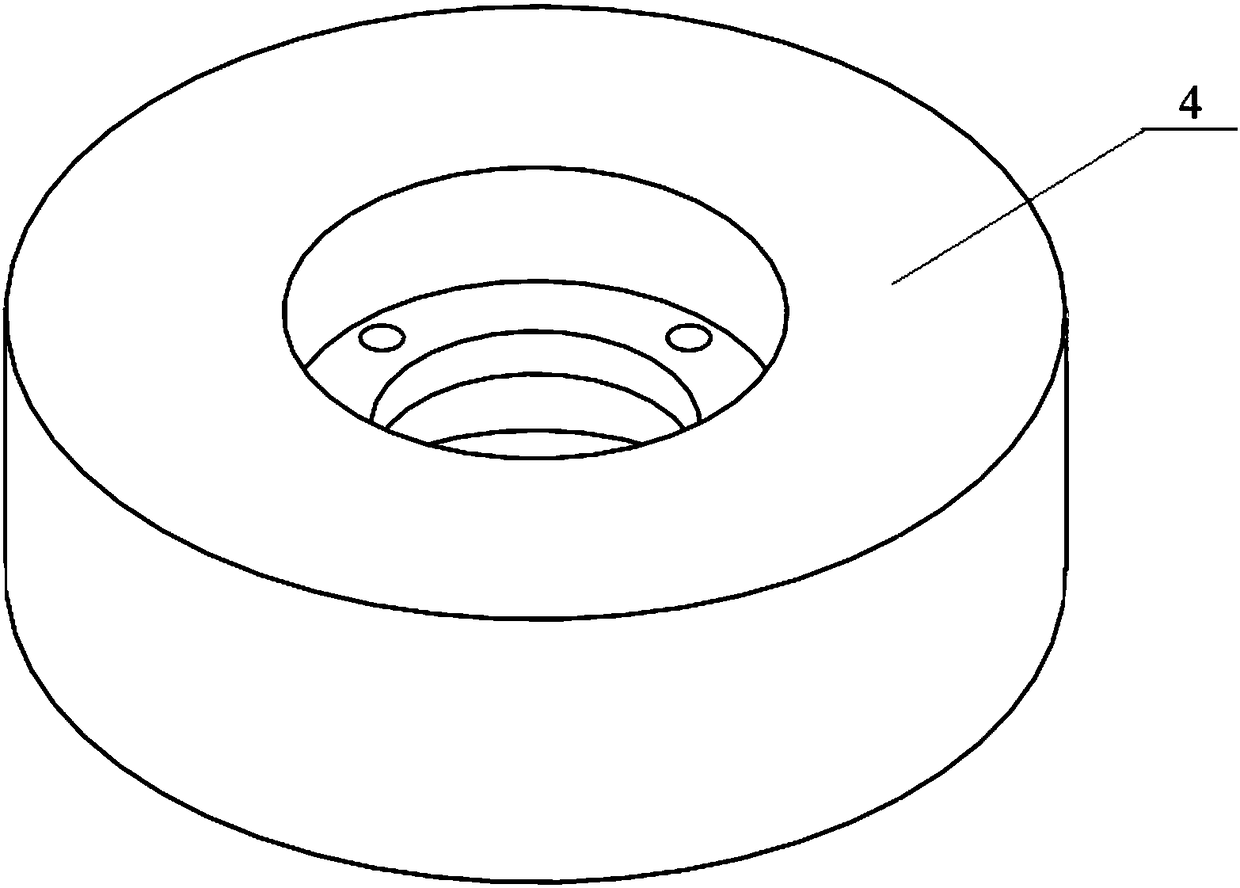

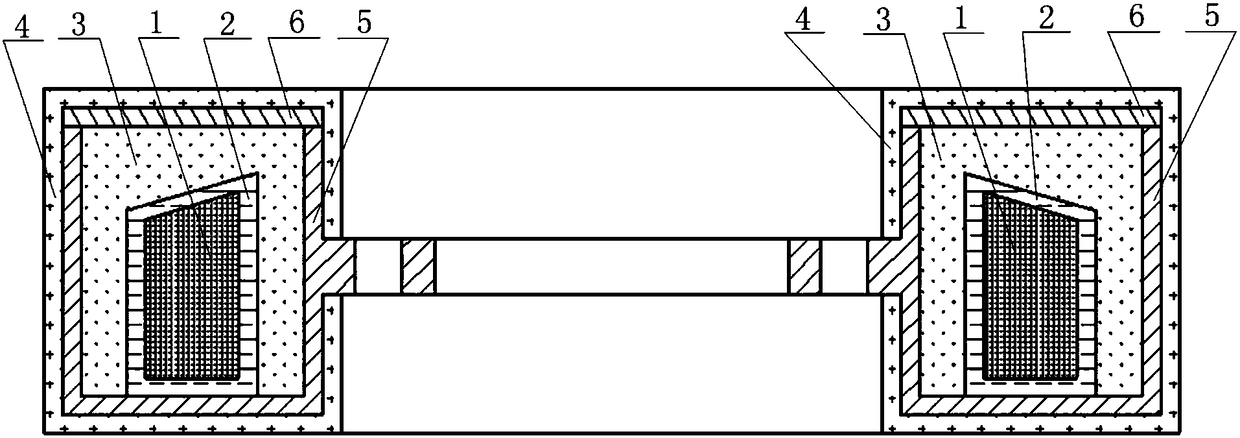

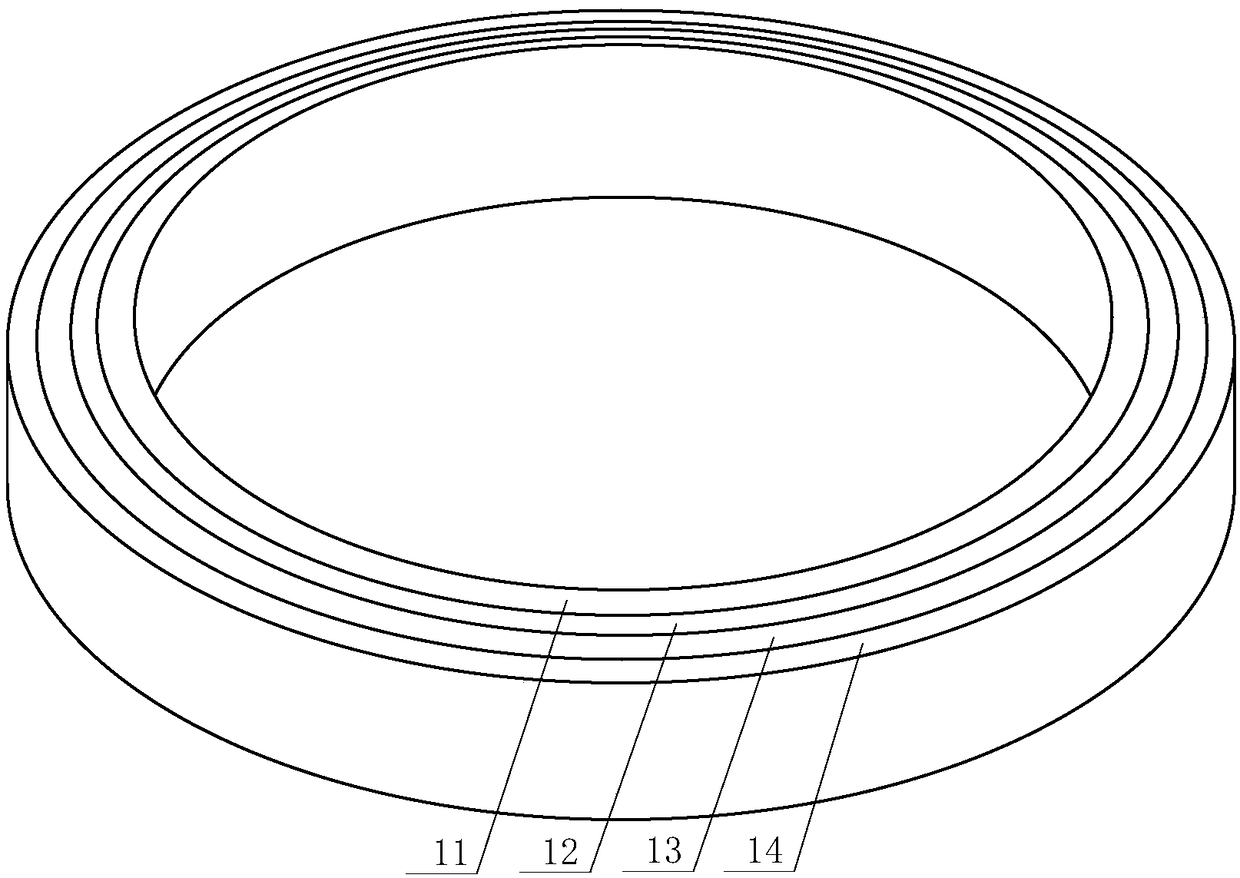

[0038] Such as figure 1 — Figure 7 As shown, the optical fiber ring of the present invention includes an optical fiber sensitive ring 1 , a magnetic shielding film 2 , a heat storage layer 3 , a magnetic shielding cover 6 , a magnetic shielding base 5 and a heat insulation layer 4 .

[0039] Such as figure 2As shown, the optical fiber sensitive ring 1, the magnetic shielding film 2, the heat storage layer 3, the magnetic shielding cover, and the heat insulation layer 4 are sequentially arranged from the inside to the outside; the magnetic shielding cover includes a magnetic shielding seat 5 and a Magnetic shielding cover 6; the magnetic shielding cover is an airtight structure, and the pigtail fiber of the optical fiber sensitive ring 1 passes through the magnetic shielding film 2 and the magnetic shielding cover successively and is connected with the Y waveguide pigtail fiber of the optical fiber gyroscope system; the heat storage layer 3 is made of heat storage material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com