Fault diagnosis method for rotary machine based on noise reduction automatic encoder and incremental learning

A technology for noise reduction, automatic coding, and rotating machinery. It is used in the testing of mechanical components, the testing of machine/structural components, and instruments. It can solve the problem of wasting time and computing resources, poor diagnosis results, and poor generalization ability of diagnostic models. problems, to achieve the effect of improving efficiency and saving computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

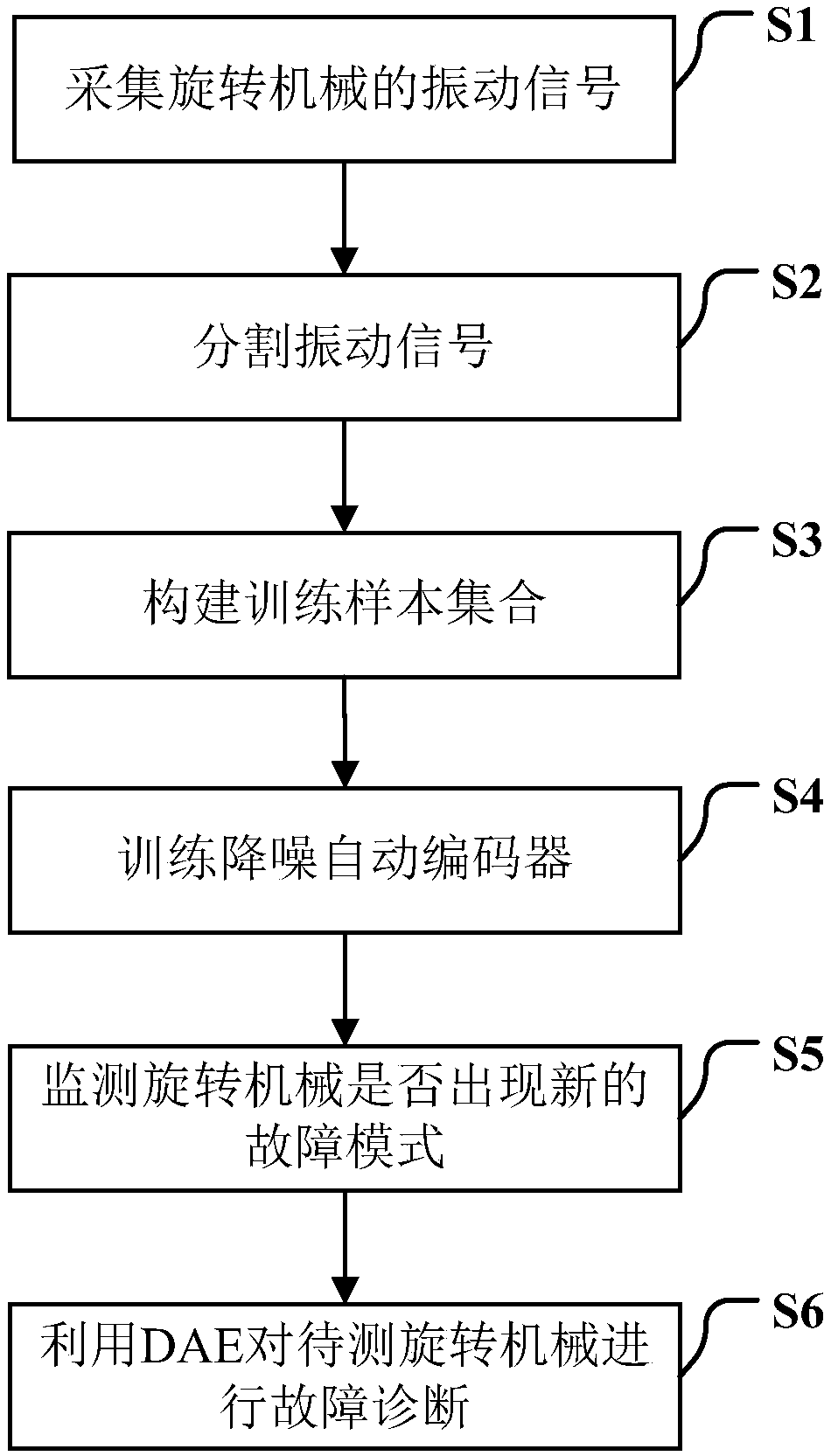

[0033] figure 1 It is a flow chart of the method for diagnosing a fault in a rotating machine based on a noise reduction autoencoder and incremental learning in the present invention.

[0034] In this example, if figure 1 As shown, a kind of rotating machinery fault diagnosis method based on noise reduction automatic encoder and incremental learning of the present invention comprises the following steps:

[0035] S1. Acquisition of vibration signals of rotating machinery

[0036] Use the vibration data acquisition instrument to separately collect the vibration signal of the rotating machinery under a single failure mode, and obtain the failure data of the rotating machinery under each type of failure mode d k , where k represents the failure mode number;

[0037] S2, split the vibration signal

[0038] For fault data d k Perform equidistant segmentation to obtain N segments of fault data, and assume that each segment of fault data contains n data points;

[0039] In this...

example

[0058] In this embodiment, taking the data collected by a high-speed train axle bearing test bench as an example, the specific process is as follows:

[0059] The bearing test bench is composed of drive motor, conveyor belt system, horizontal loading table, vertical loading table, wheel axle and wheel-to-axle box, etc. The test bearing is installed in the axle box. The bearing model used in the experiment is SKF197726. The failure mode of the bearing is shown in Table 1. For each failure mode, vibration signals under 9 working conditions are collected, as shown in Table 2, and the sampling rate is 5120Hz.

[0060] Table 1 is a list of tested bearing failure modes for diagnostic analysis;

[0061] Table 2 is a list of 9 working conditions simulated in the experiment.

[0062]

[0063]

[0064] Table 1

[0065]

[0066] Table 2

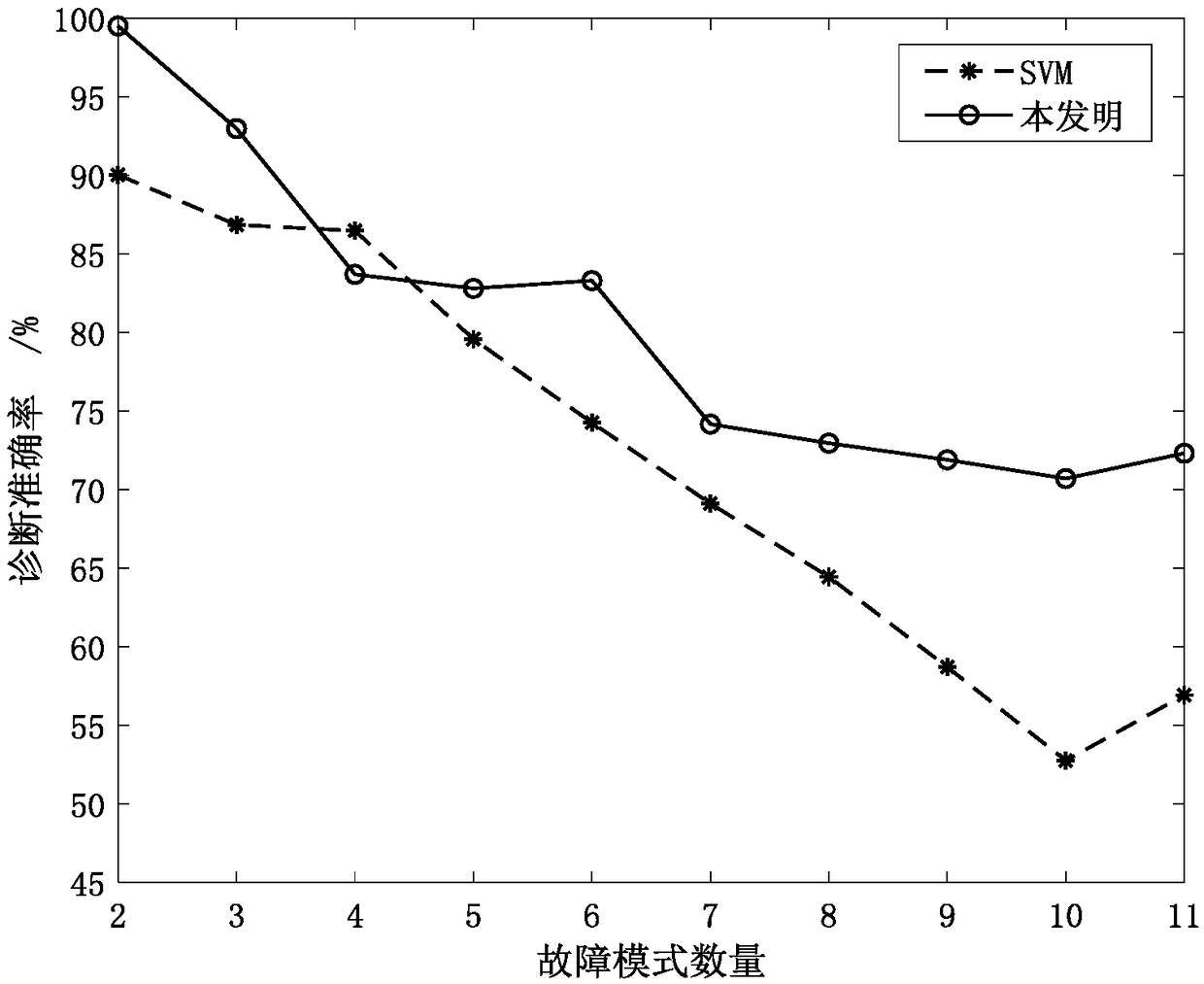

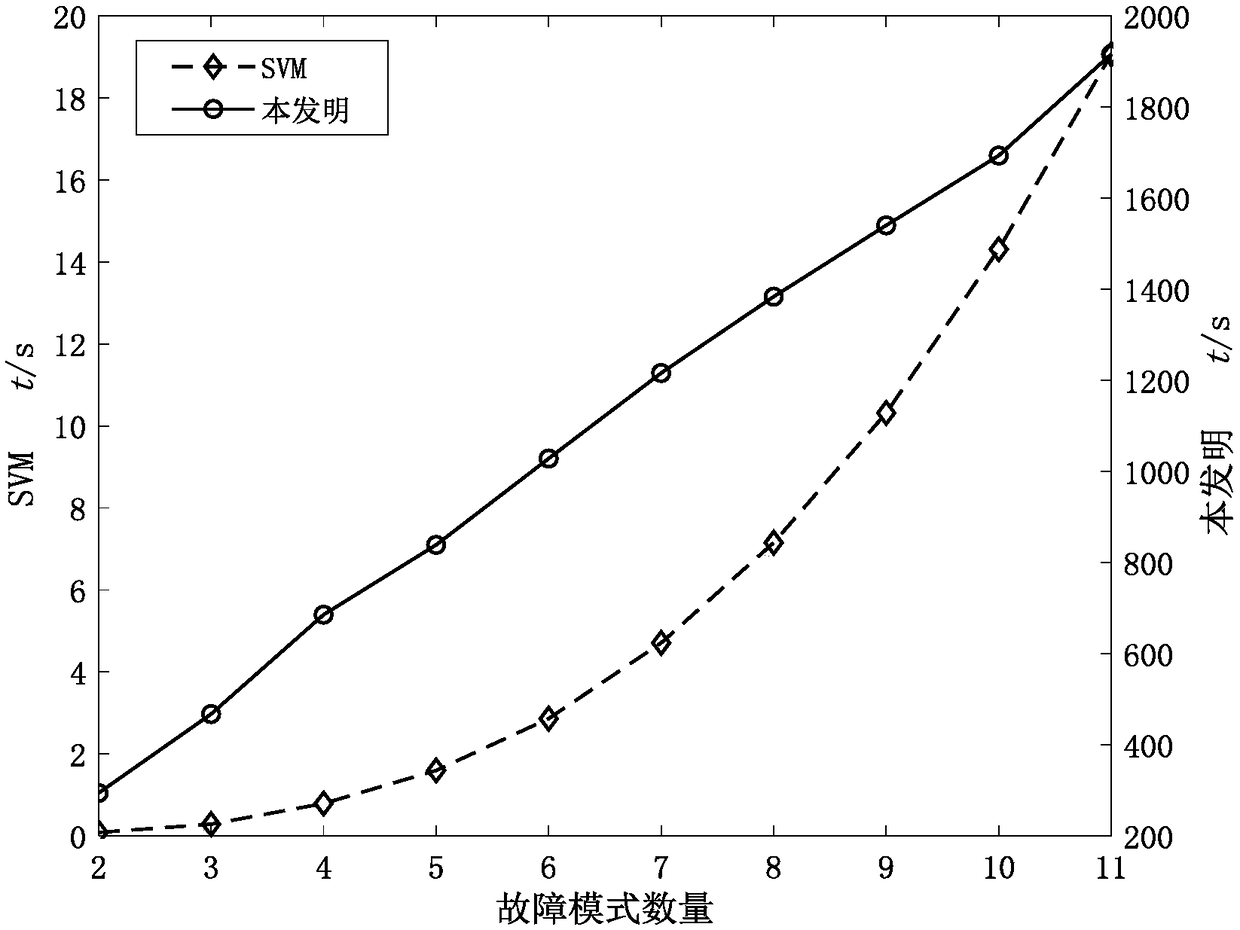

[0067] For each type of failure mode in Table 1, the number of samples is 1350, there are 11 types in total, and the total number of sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com