Feed biological mold removing agent and a preparation method thereof

A mold remover and biological technology, applied in the field of feed additives, to increase animal feed intake, wide application range, and reduce immunosuppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

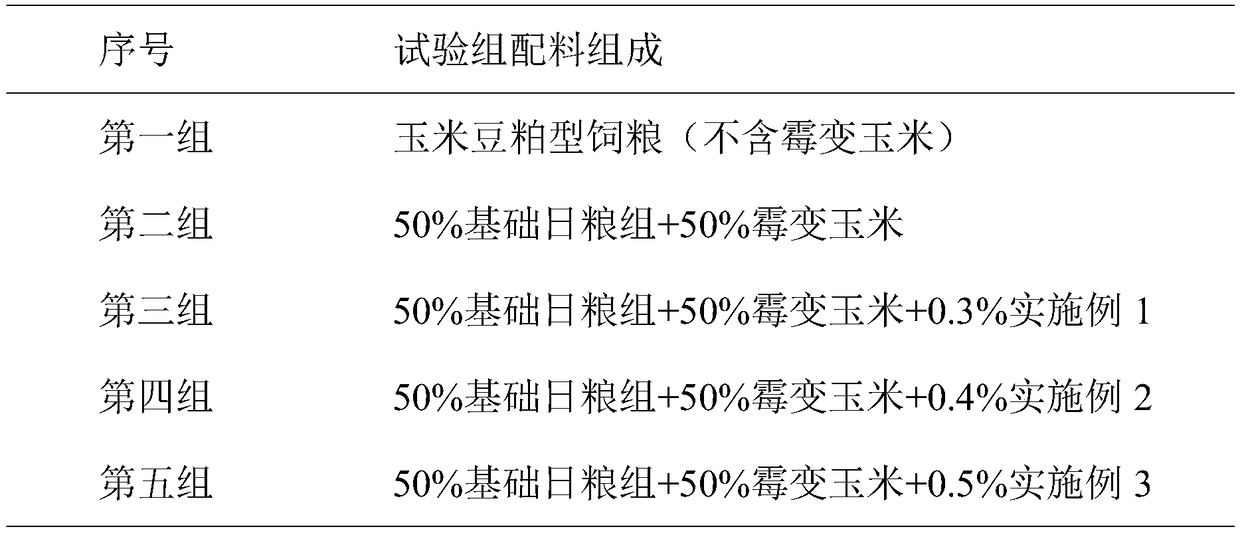

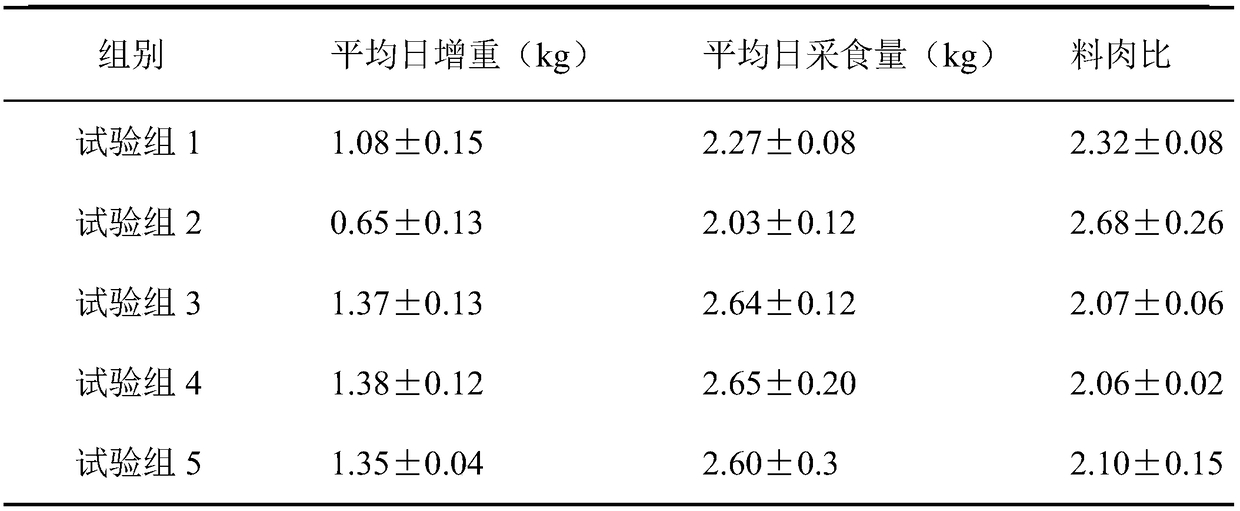

Examples

Embodiment 1

[0032] Weigh the following raw materials: 80 parts of Eucommia ulmoides, 80 parts of Ligustrum lucidum, 200 parts of astragalus, 40 parts of licorice, 50 parts of Bacillus subtilis, 30 parts of Saccharomyces cerevisiae, 20 parts of Enterococcus faecalis, 10 parts of zeolite powder, and 300 parts of Saccharomyces cerevisiae cell wall , 50 parts of glucose oxidase, 200 parts of high-purity nano-montmorillonite.

[0033]Specific preparation steps: 1) select and remove eucommia ulmoides, Ligustrum lucidum, astragalus, and licorice, then mix and pulverize them through a 40-mesh sieve; 2) pre-mix Bacillus subtilis, Saccharomyces cerevisiae, Enterococcus faecalis, and zeolite powder for 10 minutes; 3) The semi-finished product obtained in 1) and 2) is mixed with the cell wall of Saccharomyces cerevisiae, glucose oxidase, and high-purity nano-montmorillonite for 5 minutes, and then vacuum-packed to obtain the finished product.

[0034] The prepared finished feed additive is directly a...

Embodiment 2

[0036] Weigh the following raw materials: 100 parts of Eucommia ulmoides, 100 parts of Ligustrum lucidum, 240 parts of astragalus, 60 parts of licorice, 80 parts of Bacillus subtilis, 65 parts of Saccharomyces cerevisiae, 55 parts of Enterococcus faecalis, 20 parts of zeolite powder, 450 parts of Saccharomyces cerevisiae cell wall , 100 parts of glucose oxidase, 300 parts of high-purity nano-montmorillonite.

[0037] Specific preparation steps: 1) select and remove eucommia ulmoides, Ligustrum lucidum, astragalus, and licorice, then mix and pulverize them through a 40-mesh sieve; 2) pre-mix Bacillus subtilis, Saccharomyces cerevisiae, Enterococcus faecalis, and zeolite powder for 10 minutes; 3) The semi-finished product obtained in 1) and 2) is mixed with the cell wall of Saccharomyces cerevisiae, glucose oxidase, and high-purity nano-montmorillonite for 5 minutes, and then vacuum-packed to obtain the finished product.

[0038] The prepared finished feed additive is directly a...

Embodiment 3

[0040] Weigh the following raw materials: 90 parts of Eucommia ulmoides, 90 parts of Ligustrum lucidum, 220 parts of astragalus, 50 parts of licorice, 65 parts of Bacillus subtilis, 45 parts of Saccharomyces cerevisiae, 35 parts of Enterococcus faecalis, 15 parts of zeolite powder, and 370 parts of Saccharomyces cerevisiae cell wall , 75 parts of glucose oxidase, 250 parts of high-purity nano-montmorillonite.

[0041] Specific preparation steps: 1) select and remove eucommia ulmoides, Ligustrum lucidum, astragalus, and licorice, then mix and pulverize them through a 40-mesh sieve; 2) pre-mix Bacillus subtilis, Saccharomyces cerevisiae, Enterococcus faecalis, and zeolite powder for 10 minutes; 3) The semi-finished product obtained in 1) and 2) is mixed with the cell wall of Saccharomyces cerevisiae, glucose oxidase, and high-purity nano-montmorillonite for 5 minutes, and then vacuum-packed to obtain the finished product.

[0042] The prepared finished feed additive is directly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com