Microsphere controllable equipment based on optical tweezers and operation method

A technology of microspheres and optical tweezers, which is applied in the preparation of microspheres, microcapsule preparations, chemical/physical/physicochemical processes of applying energy, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

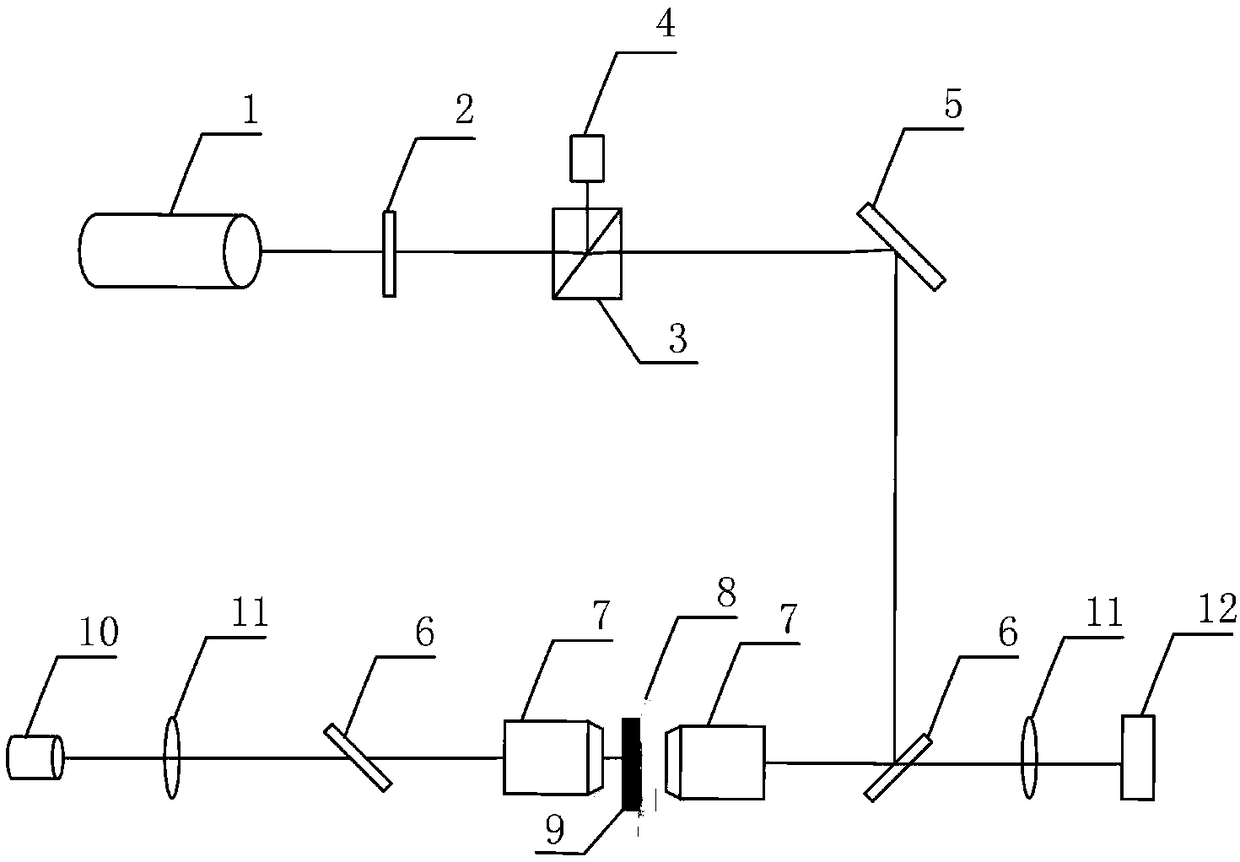

[0017] The method and device for controllable preparation and manipulation of microspheres based on optical tweezers of the present invention will be described in detail below with reference to the embodiments and accompanying drawings.

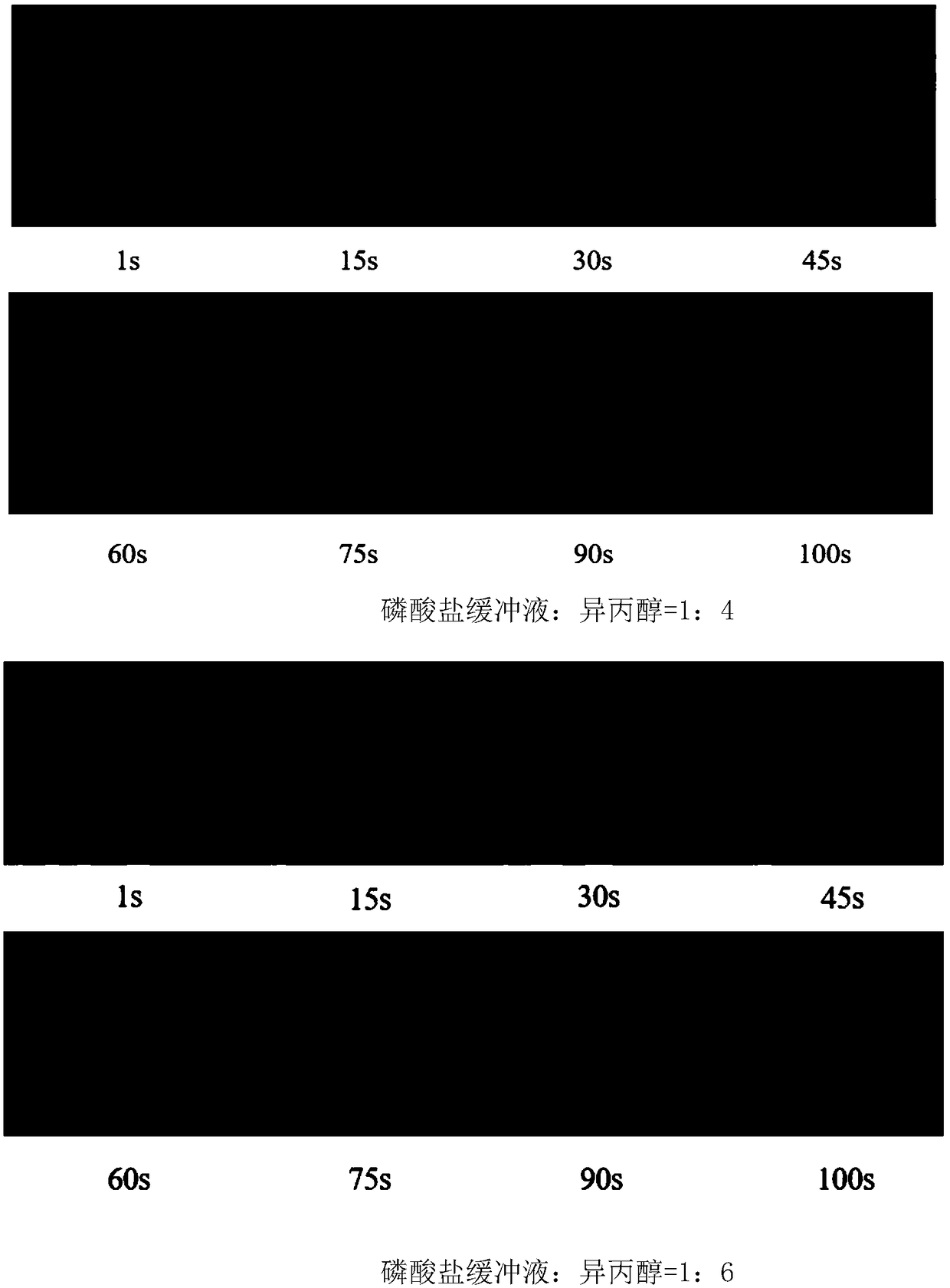

[0018] The two solutions used to prepare the microspheres in the experiment are phosphate buffer saline PBS (commercially available, the pH of PBS is 7.2-7.4, and the main components are potassium dihydrogen phosphate, disodium hydrogen phosphate, sodium chloride and potassium chloride) and isopropanol (commercially available, molecular weight is 60.10, isopropanol content is not less than 99.9%, water content 0.01%), when the volume ratio of the two solutions is 1:1, no microspheres are generated; when phosphate buffer When the volume ratio of liquid and isopropanol organic solvent is 1:3, 1:4, 1:5, 1:6, 1:8, microspheres will be formed, but the microspheres under the conditions of different volume ratios of the two solutions The growth rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com