Bismuth beneficiation, a beneficiation method instead of sodium cyanide

A beneficiation method and sodium cyanide technology, applied in the field of bismuth beneficiation, can solve problems such as complicated operation process, great safety hazard, waste of resources, etc., and achieve the effect of improving the beneficiation index, improving safety and saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

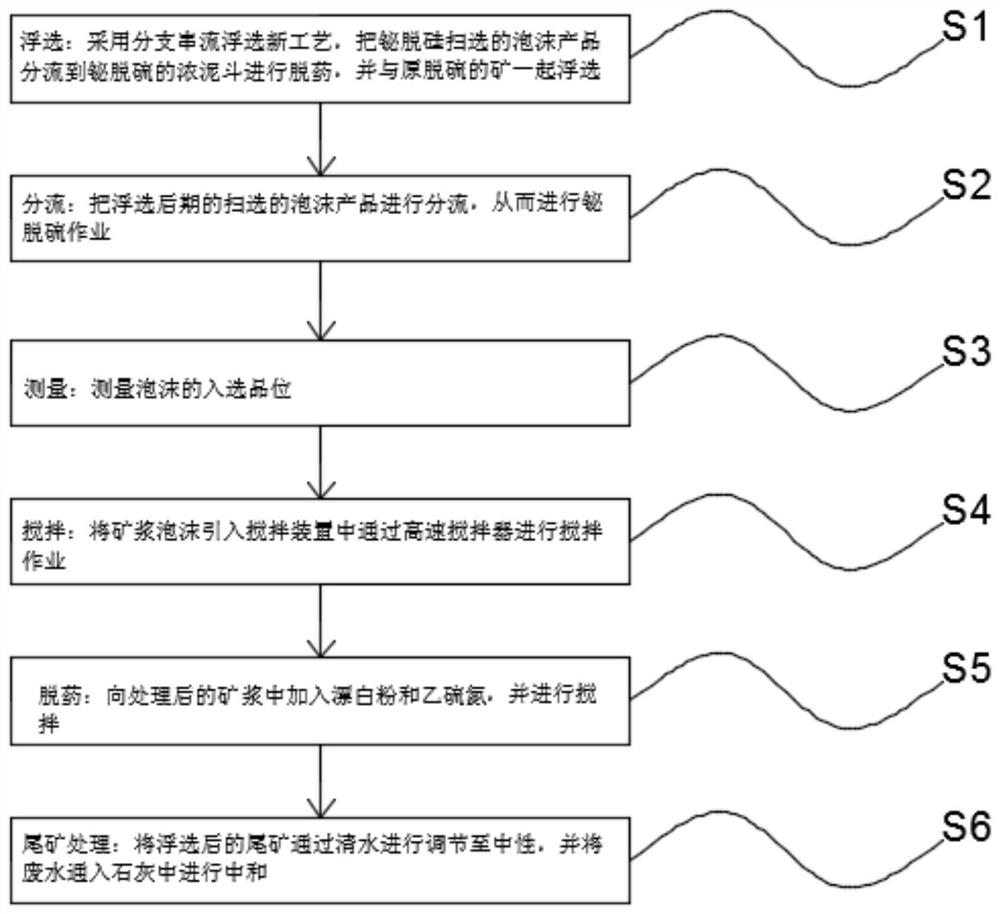

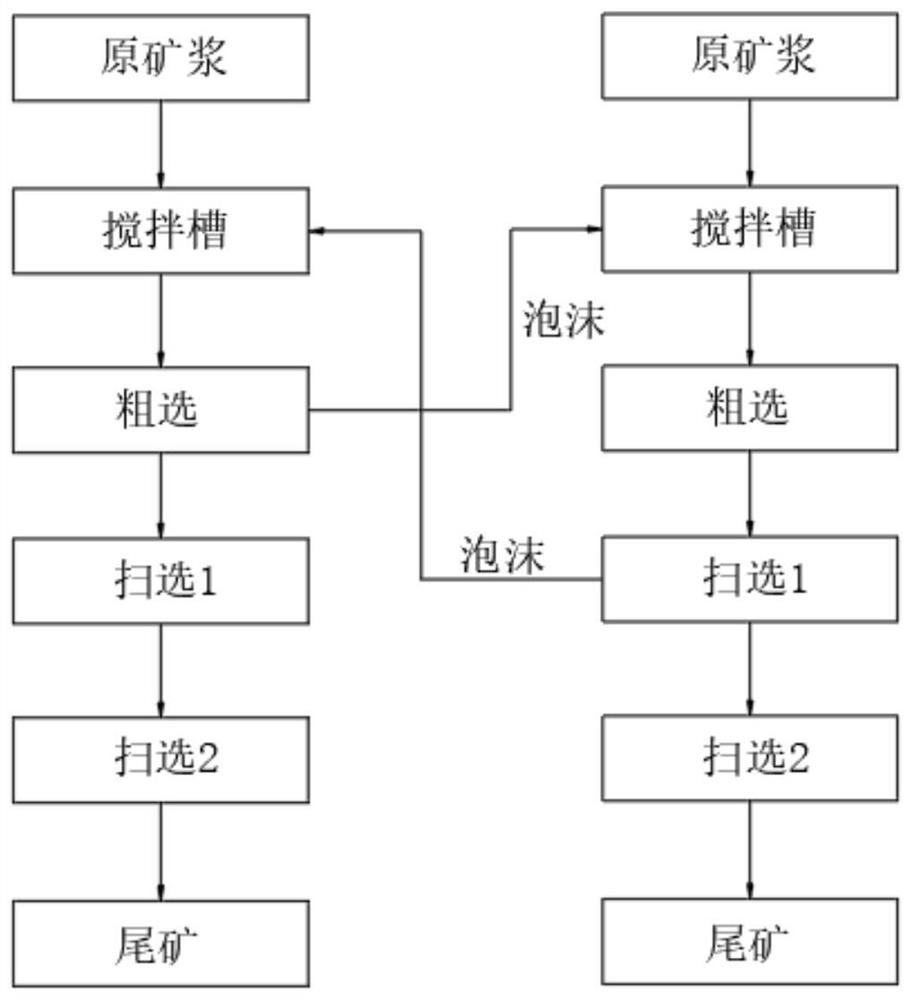

[0031] Embodiment 1: as figure 1 and figure 2 Shown, bismuth selects a kind of beneficiation method that replaces sodium cyanide, comprises the following steps:

[0032] S1. Flotation: A new branch series flow flotation process is adopted to divert the foam products of bismuth desiliconization and sweeping to the thick mud bucket of bismuth desulfurization for drug removal, and float together with the desulfurization ore;

[0033] S2, shunting: shunting the foam products swept in the later stage of flotation, so as to carry out bismuth desulfurization operation;

[0034] S3. Measurement: measure the selected grade of the diverted foam;

[0035] S4. Stirring: After the measurement, the foam is introduced into the stirring device and stirred by a high-speed stirrer;

[0036] S5, drug removal: add bleaching powder and ethyl disulfide to the stirred pulp;

[0037] S6. Tailings treatment: the flotation tailings are adjusted to be neutral, and the waste water separated from the...

Embodiment 2

[0052]Embodiment 2: a kind of beneficiation method of bismuth beneficiation instead of sodium cyanide comprises the following steps:

[0053] S1. Flotation: A new branch series flow flotation process is adopted to divert the foam products of bismuth desiliconization and sweeping to the thick mud bucket of bismuth desulfurization for drug removal, and float together with the desulfurization ore;

[0054] S2, shunting: shunting the foam products swept in the later stage of flotation, so as to carry out bismuth desulfurization operation;

[0055] S3. Measurement: measure the selected grade of the diverted foam;

[0056] S4. Stirring: After the measurement, the foam is introduced into the stirring device and stirred by a high-speed stirrer;

[0057] S5, drug removal: add activated carbon and ethyl disulfide to the stirred pulp;

[0058] S6. Tailings treatment: the flotation tailings are adjusted to be neutral, and the waste water separated from the tailings is passed into lime f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com