A kind of 2.25cr1mo0.25v steel large cylinder forging combined forging and rolling manufacturing method

A 2.25cr1mo0.25v, large cylinder technology, applied in the direction of metal rolling, metal processing equipment, etc., can solve the problems of multiple fires to produce finished products, multiple hole reaming, etc., to reduce operating hours, shorten processing procedures, improve The effect of product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The 2.25Cr1Mo0.25V steel large cylinder forging combined forging and rolling manufacturing method of this embodiment includes the following steps:

[0042] (1) 2.25Cr1Mo0.25V steel smelting and ingot casting. Process flow: electric furnace→refining furnace→vacuum casting. It mainly meets the requirements of furnace body inclusions and raw materials, as well as the process parameters of electric furnace, refining furnace and ingot casting process. Specifically, the steel tapping conditions are guaranteed: the composition and temperature of 2.25Cr1Mo0.25V steel meet the requirements. The 2.25Cr1Mo0.25V steel ingot adopts the 24-edge ingot type with upper injection, and the weight of the ingot is 222t. The ingot quality is guaranteed by a series of parameters of the vacuum pouring system, including: vacuum argon blowing, pouring speed and temperature, etc.

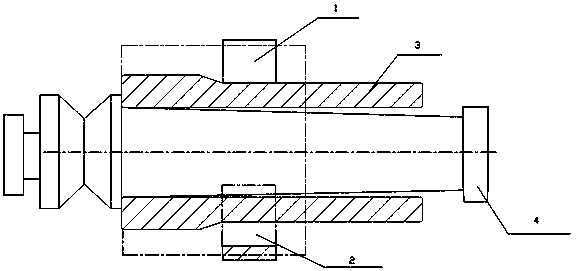

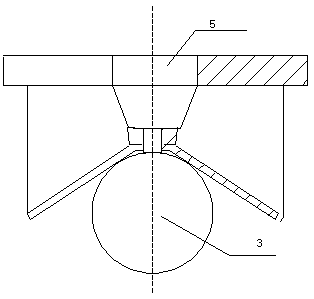

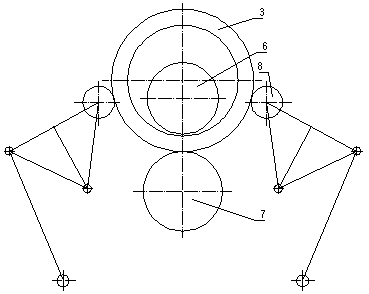

[0043] (2) 2.25Cr1Mo0.25V steel large cylinder forging combined forging and rolling forming process. Forming pro...

Embodiment 2

[0059] The 2.25Cr1Mo0.25V steel large cylinder forging combined forging and rolling manufacturing method of this embodiment includes the following steps:

[0060] (1) 2.25Cr1Mo0.25V steel smelting and ingot casting. Process flow: electric furnace→refining furnace→vacuum casting. The 2.25Cr1Mo0.25V steel ingot adopts the upper injection 24 edge ingot type, and the weight of the ingot is 249t. The ingot quality is guaranteed by a series of parameters of the vacuum pouring system, including: vacuum argon blowing, pouring speed and temperature, etc.

[0061] (2) 2.25Cr1Mo0.25V steel large cylinder forging combined forging and rolling forming process. Forging-rolling combined forming process: 2.25Cr1Mo0.25V steel large cylinder forging combined forging-rolling forming process. Forming process combined with forging and rolling: gas cutting → upsetting → punching → mandrel elongation → horse bar reaming → barrel section rolling mill rolling. The specific process regulations formu...

Embodiment 3

[0077] The 2.25Cr1Mo0.25V steel large cylinder forging combined forging and rolling manufacturing method of this embodiment includes the following steps:

[0078] (1) 2.25Cr1Mo0.25V steel smelting and ingot casting. Process flow: electric furnace→refining furnace→vacuum casting. It mainly meets the requirements of furnace body inclusions and raw materials, as well as the process parameters of electric furnace, refining furnace and ingot casting process. Specifically, the steel tapping conditions are guaranteed: the composition and temperature of 2.25Cr1Mo0.25V steel meet the requirements. The 2.25Cr1Mo0.25V steel ingot adopts the upper injection 24 edge ingot type, and the weight of the ingot is 249t. The ingot quality is guaranteed by a series of parameters of the vacuum pouring system, including: vacuum argon blowing, pouring speed and temperature, etc.

[0079] (2) 2.25Cr1Mo0.25V steel large cylinder forging combined forging and rolling forming process. Forging-rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com