Ingot cooling method and water circulation cooling device specially designed for method

A technology of water circulation cooling and cooling method, applied in the field of ingot cooling, can solve the problems of labor consumption, water splashing, affecting production, etc., and achieve the effects of good cooling effect, uniform cooling, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings:

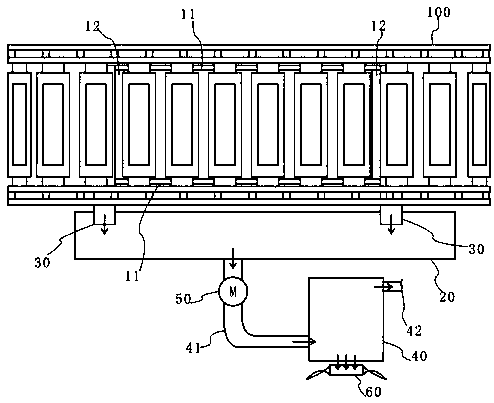

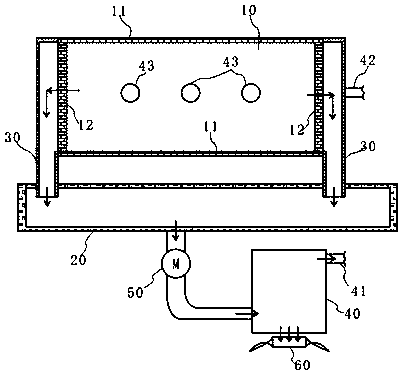

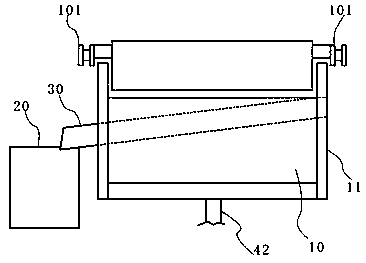

[0031] This embodiment provides an ingot cooling method, which is different from the traditional method in which cooling water is sprayed on the surface of the ingot mold. The ingot cooling method in this embodiment is to install a cooling water tank 10 below the conveyor chain machine 100. The cooling water tank The side plates A11 of the width direction 10 are higher than the bottom surface of the mold, and the drain ports 13 are left between the two side plates B12 in the longitudinal direction and the bottom surface of the mold. The ability of cooling water at a suitable height on the bottom surface of the mold, so that the lower part of the ingot mold is immersed under the cooling liquid surface during the cooling process, and the drainage port 13 is used to continuously drain outwards, with the appropriate water inlet rate to The cooling water in the cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com