Gun drills of deep-hole digital controlled drilling machine

A technology of CNC drilling machine and gun drilling, which is applied in the parts of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc. High positioning accuracy, high precision, and the effect of optimizing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

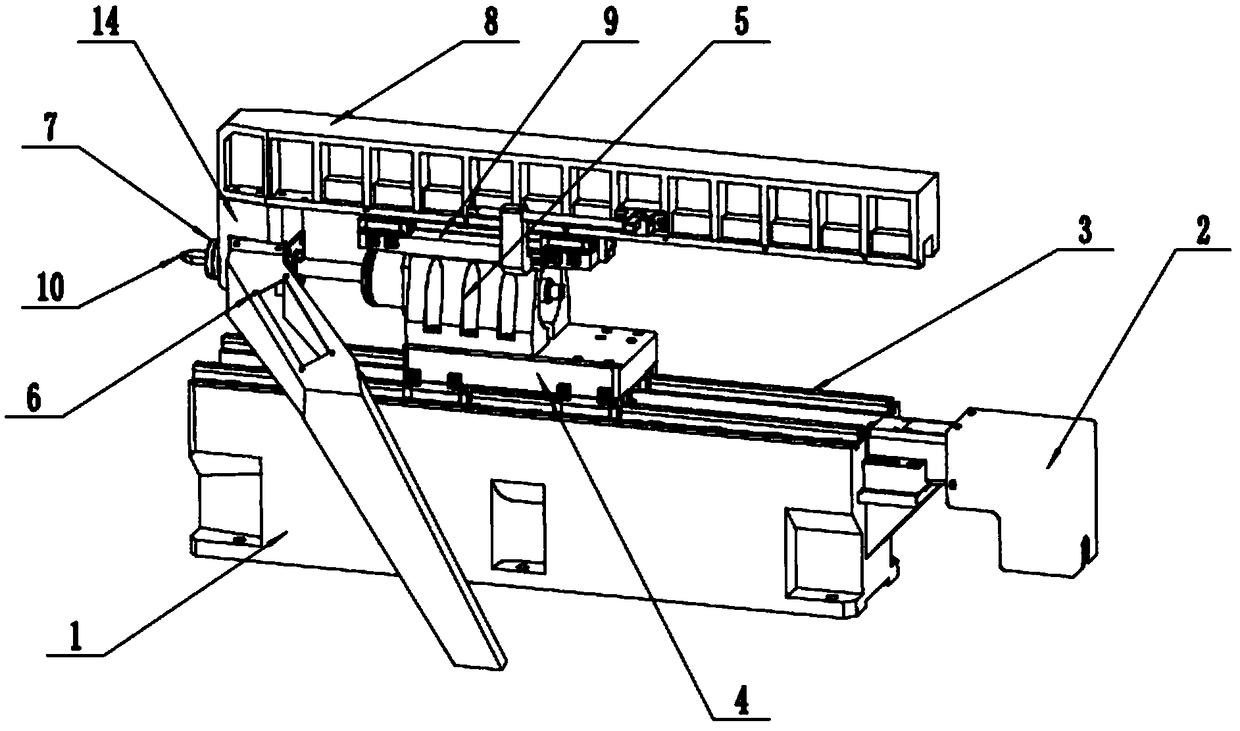

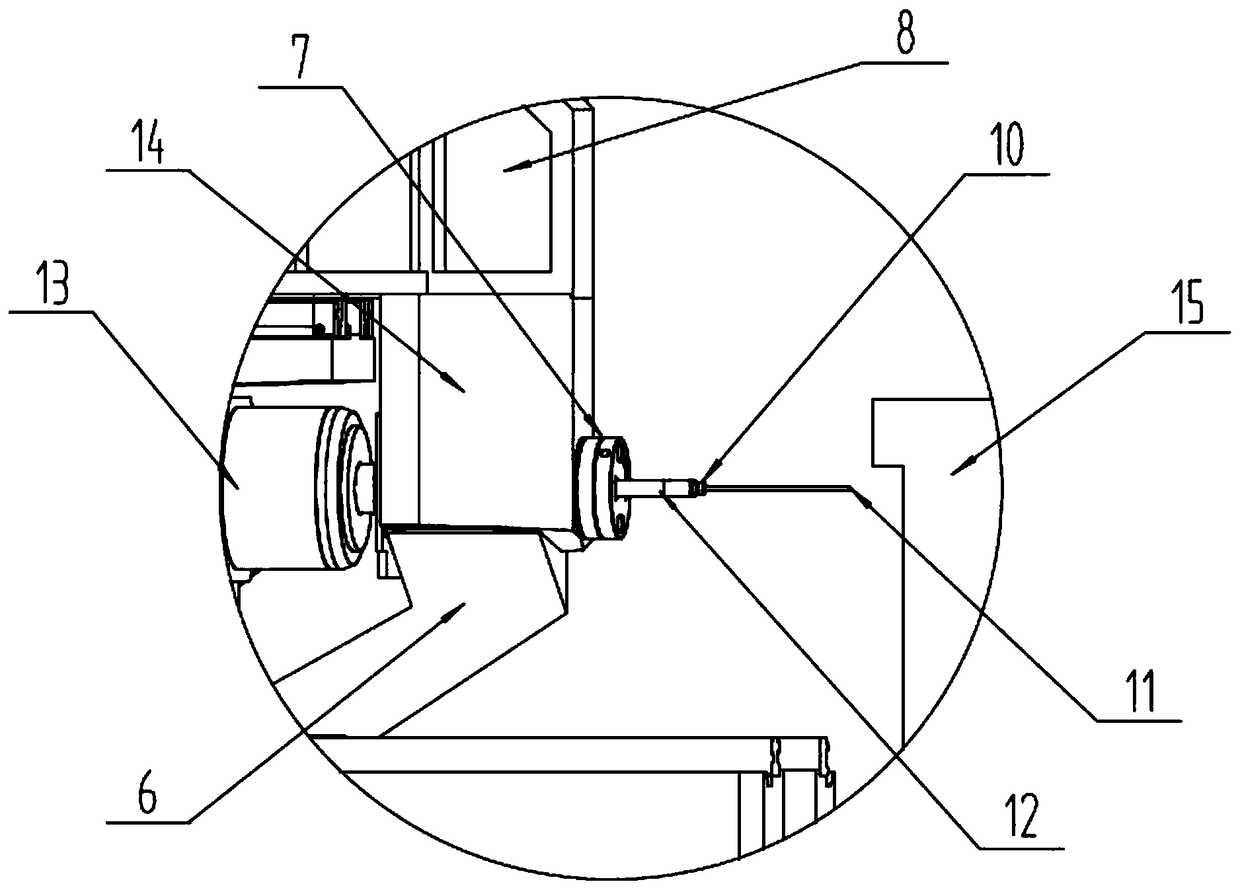

[0027] Such as Figure 1-2 As shown, this embodiment provides a gun drill for a deep-hole CNC drilling machine. In order to meet the requirements of the deep-hole CNC drilling machine using a horizontal single-row drilling machine, since the ring die workpiece is set axially upward, the gun drill needs to be processed along the ring die. Evenly distributed around the surface.

[0028] Such as figure 1 As shown, the gun drill of the deep hole CNC drilling machine of the present embodiment includes a guide rail, a gun drill and a guide arm 8, and the above guide rail, gun drill and guide arm 8 are all arranged along the Z-axis direction, and the guide rail includes a guide rail base 1, a linear guide rail 3, Move the pallet 4 and the servo motor 2, the upper part of the guide rail base 1 is the linear guide rail 3, the linear guide rail 3 is two single-line tracks and distributed on both sides of the top of the guide rail base 1, the middle part of the linear guide rail 3 is a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap