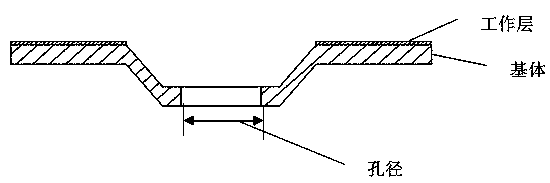

Environment-friendly resin cymbals-type grinding wheel

An environmentally friendly resin, cymbal-type technology, used in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of poor grinding performance, easy burns of workpieces, easy falling off of abrasives, etc., to improve surface quality and impact resistance, avoid The effect of workpiece burn and severe falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

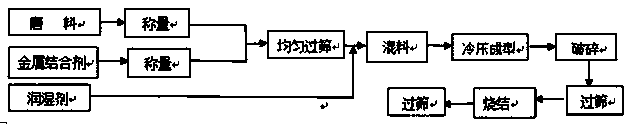

[0030] a. Granulation of precursor abrasive: sieve and mix 60% CBN abrasive and 38% metal bond (65% Cu powder, 20% Sn powder, 10% Fe powder, 5% Ni powder), and add 2 % wetting agent is mixed evenly for agglomeration and nucleation, and then grows into massive particles after cold pressing. Crush and sieve the blocky particles to obtain the required sintered abrasive, put the abrasive into a microwave sintering furnace for rapid sintering and keep it at 720°C for 120 minutes.

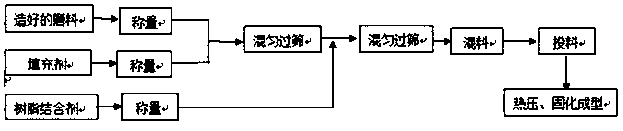

[0031] b. Sieve and mix 51% of cBN abrasive, 15% aluminum-magnesium hydrotalcite filler, and 4% diamond filler, then add 30% silicone oil modified phenolic resin binder, sieve and mix evenly, and The mixing was carried out in a high speed mixer for 2 hours. Store the mixed abrasives under closed conditions at room temperature for 8 hours, then feed the mixed abrasives in an environment with a humidity of 50%. Coat a thin layer of liquid resin on the substrate, throw the abrasive evenly on the substrate...

Embodiment 2

[0033] a. Granulation of precursor abrasive: sieve and mix 50% CBN abrasive and 46% metal bond (65% Cu powder, 20% Sn powder, 10% Fe powder, 5% Ni powder), and add 4 % wetting agent is mixed evenly for agglomeration and nucleation, and then grows into massive particles after cold pressing. Crush and sieve the massive particles to obtain the required sintered abrasive, put the abrasive into a microwave sintering furnace for rapid sintering and keep it at 760°C for 60 minutes.

[0034] b. Sieve and mix 51% of cBN abrasive, 14% aluminum-magnesium hydrotalcite filler, and 5% diamond filler, then add 35% silicone oil modified phenolic resin binder, sieve and mix evenly, and The mixing was carried out in a high speed mixer for 2 hours. The mixed abrasives were stored under closed conditions at room temperature for 8 hours, and the mixed abrasives were fed in an environment with a humidity of 45%. Coat a thin layer of liquid resin on the substrate, throw the abrasive evenly on the ...

Embodiment 3

[0036] a. Granulation of precursor abrasive: sieve and mix 47% of CBN abrasive and 48% of metal bond (65% of Cu powder, 20% of Sn powder, 10% of Fe powder, 5% of Ni powder), and add 5% % wetting agent is mixed evenly for agglomeration and nucleation, and then grows into massive particles after cold pressing. Crush and sieve the massive particles to obtain the required sintered abrasive, put the abrasive into a microwave sintering furnace for rapid sintering and keep it at 680°C for 120 minutes.

[0037] b. sieve and mix 51% of cBN abrasive, 27% aluminum-magnesium hydrotalcite filler, and 10% diamond filler, then add 20% silicone oil modified phenolic resin binder, sieve and mix evenly, and The mixing was carried out in a high speed mixer for 2 hours. Store the mixed abrasives under closed conditions at room temperature for 8 hours, and feed the mixed abrasives in an environment with a humidity of 40%. Coat a thin layer of liquid resin on the substrate, throw the abrasive eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com