Acid soil improver

A technology of acidic soil and improver, applied in application, animal carcass fertilizer, agriculture, etc., can solve the problems of desulfurization ash utilization mode and application range limitation, low utilization rate of desulfurization agent, difficult process control, etc., to achieve the promotion of types and quantities The effect of increasing, protecting the environment and increasing crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

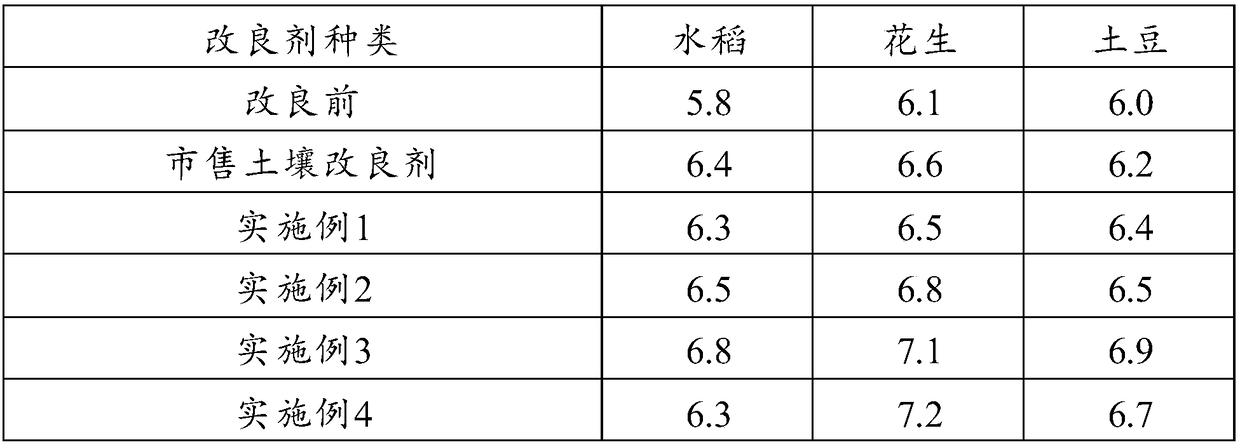

Examples

Embodiment 1

[0029] The weight percent of an acidic soil improver is as follows: semi-dry desulfurization ash: 25%, straw: 30%, oyster shell powder: 30%, magnesium sulfate: 7%, zinc sulfate: 8%;

[0030] The weight percent of semi-dry desulfurization ash is as follows: 40.0 parts by weight of SiO 2 , 14.8 parts by weight of Al 2 o 3 , 4.2 parts by weight of Fe 2 o 3 , 27.1 parts by weight of CaO, 2.9 parts by weight of MgO, 3.8 parts by weight of K 2 O, 4.8 parts by weight of Na 2 O and 2.4 parts by weight of P 2 o 5 ;

[0031] The fineness of semi-dry desulfurization ash is 45μm, and the sieve residue is not more than 15%; the straw is crushed to 5-100mm; the oyster shell powder fineness is 45μm, and the sieve residue is not more than 15%; magnesium sulfate, zinc sulfate The fineness is 45μm square hole sieve and the sieve residue is not more than 10%.

Embodiment 2

[0033]The weight percent of an acidic soil improver is as follows: semi-dry desulfurization ash: 30%, straw: 25%, oyster shell powder: 30%, magnesium sulfate: 7%, zinc sulfate: 8%;

[0034] The weight percent of semi-dry desulfurization ash is as follows: 45.0 parts by weight of SiO 2 , 11.6 parts by weight of Al 2 o 3 , 3.8 parts by weight of Fe 2 o 3 , 25.3 parts by weight of CaO, 2.5 parts by weight of MgO, 3.8 parts by weight of K 2 O, 4.9 parts by weight of Na 2 O and 2.9 parts by weight of P 2 o 5 ;

[0035] The fineness of semi-dry desulfurization ash is 45μm, and the sieve residue is not more than 15%; the straw is crushed to 5-100mm; the oyster shell powder fineness is 45μm, and the sieve residue is not more than 15%; magnesium sulfate, zinc sulfate The fineness is 45μm square hole sieve and the sieve residue is not more than 10%.

Embodiment 3

[0037] The percentage by weight of an acidic soil improver is as follows: semi-dry desulfurization ash: 35%, straw: 25%, oyster shell powder: 25%, magnesium sulfate: 7%, zinc sulfate: 8%;

[0038] The weight percent of semi-dry desulfurization ash is as follows: 50.0 parts by weight of SiO 2 , 10.3 parts by weight of Al 2 o 3 , 4.7 parts by weight of Fe 2 o 3 , 22.2 parts by weight of CaO, 2.6 parts by weight of MgO, 3.4 parts by weight of K 2 O, 4.0 parts by weight of Na 2 O and 2.8 parts by weight of P 2 o 5 ;

[0039] The fineness of semi-dry desulfurization ash is 45μm, and the sieve residue is not more than 15%; the straw is crushed to 5-100mm; the oyster shell powder fineness is 45μm, and the sieve residue is not more than 15%; magnesium sulfate, zinc sulfate The fineness is 45μm square hole sieve and the sieve residue is not more than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com